What Are the Benefits of Silicone Tubing in Peristaltic Pumps

Peristaltic pumps are crucial in many industries, handling fluids with precision. These pumps use flexible tubes to efficiently move liquids.

Silicone peristaltic pump tubing is an excellent choice due to its unique properties. Selecting the right tubing material enhances pump performance and longevity. Additionally, the right material prevents contamination and maintains consistent flow rates, which is vital for medical, pharmaceutical, and food applications.

Overview of Peristaltic Pumps

How Peristaltic Pumps Work

Basic Mechanism

Peristaltic pumps work using peristalsis. Rollers squeeze a flexible tube, pushing fluid forward. This keeps the fluid inside the tube, away from pump parts. No valves or seals touch the fluid, so there's less clogging and maintenance. These pumps are great for precise dosing.

Applications in Various Industries

Many industries use peristaltic pumps. In pharmaceuticals, they move fluids accurately. The food industry uses them to stay clean. Chemicals need these pumps for tough fluids. They also help in water treatment and labs.

Importance of Tubing Material in Peristaltic Pumps

Factors to Consider

Choosing the right tubing is important for good pump performance. Durable tubes last longer. Chemical-friendly tubes don't react with fluids. Flexible tubes are easy to install and use smoothly. Medical and pharma needs biocompatible tubes. All these factors make the pump work well.

Common Materials Used

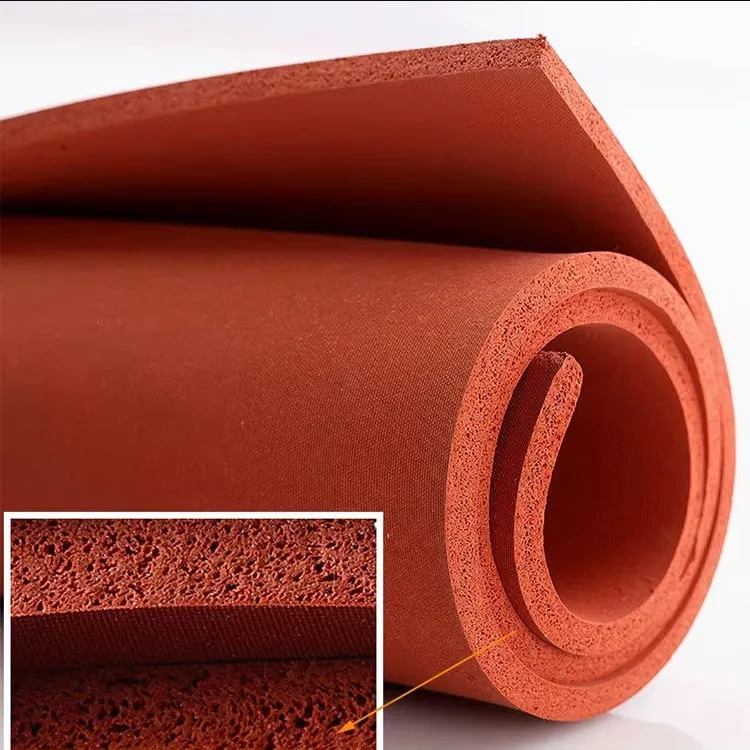

Different materials are used for tubing in these pumps. Silicone is flexible and strong, lasting a long time without wearing out easily. It handles chemicals well, fitting many uses. PVC resists chemicals but isn't as flexible as silicone. Tygon is both chemical-resistant and flexible but not as durable as silicone. Each material fits different needs.

Benefits of Silicone Tubing in Peristaltic Pumps

Strong and Lasting

Tough Against Damage

Silicone tubing is tough. It doesn't wear out easily. This means it lasts a long time, even with heavy use. So, industries don't need to replace it often.

Long Lifespan

Silicone tubing works well for a long time. It can handle many squeezes and releases without breaking. This makes it good for long-term use. It also saves money on maintenance.

Handles Chemicals Well

Chemical Resistant

Silicone tubing resists chemicals well. It doesn't react or break down when used with different chemicals. This makes it useful in many industries.

Used in Chemical Work

Chemical industries like silicone tubing because it handles chemicals safely. It doesn't corrode or degrade, keeping fluids pure and safe.

Flexible and Stretchy

Easy to Install

Silicone tubing is easy to install. It bends into tight spaces without breaking. This makes setup quick and simple.

Works Under Pressure

Silicone tubing stays strong under pressure. It goes back to its shape after being squeezed. This keeps the flow steady and reliable.

Safe for the Body

Used in Hospitals

Silicone tubes are important in hospitals. They help deliver medicine. The tubes make sure the medicine flows right. Labs use these tubes for tests too. The flexible tubes fit into tricky places easily.

Medical tools need safe materials. Silicone tubes are safe for the body. They don't react with body parts or fluids. This makes them good for medical use. The tubes don't cause contamination, keeping patients safe.

Safe and Non-Toxic

Safety is key in medicine and drugs. Silicone tubes are very safe to use. They are non-toxic, so they won't harm anything sensitive. The material doesn't leak bad stuff into the fluid, keeping it clean.

Silicone tubes can handle hot and cold temperatures well. They don't break down easily when sterilized with steam, which keeps things clean in hospitals.

The tubes also resist ozone and UV light, which stops them from wearing out quickly. This means they last a long time and save money because they don’t need to be replaced often.

Practical Uses of Silicone Pump Tubing

Medical and Drug Industries

Medicine Delivery

Silicone pump tubing is key in giving medicine. Hospitals use these tubes to make sure medicine flows right. The flexible tubes fit into tricky medical devices. Silicone is safe and doesn't react with medicine, keeping it pure.

Lab Tools

Labs need silicone pump tubing for many jobs. The tubing handles different chemicals without breaking down. This makes it good for tests and experiments. It lasts a long time, so labs don't need new tubes often. Easy setup helps lab work go faster.

Food and Drink Industry

Clean Fluid Moving

Silicone pump tubing keeps fluids clean in food and drinks. It doesn't cause contamination. Silicone has no smell or taste, so food stays the same flavor. Flexible tubes fit into tight spots in machines.

Meets Safety Rules

Silicone pump tubing follows strict food safety rules. It can handle high heat, making it easy to clean with steam. This keeps the tubes safe to use. Long-lasting silicone cuts down on repair costs for factories.

Industrial Uses

Chemical Work

Chemical plants use silicone pump tubing because it's tough against chemicals. The material doesn’t rust, keeping chemicals pure. Durable tubing stands up to rough industrial places.

Water Cleaning

Water treatment plants trust silicone pump tubing for steady flow rates needed for cleaning water well. The strong material lasts long without wearing out quickly, saving money on replacements.