Our large-diameter silicone tubing refers to hollow channels made of silicone rubber with inner diameters ranging from 20mm to 70mm. This type of tubing offers excellent flexibility, durability, and resistance to extreme temperatures and chemicals. Various industries, including automotive, pharmaceutical, and food processing, rely on large diameter silicone tubing for its versatility and reliability. The tubing's ability to withstand a wide temperature range from -40℃ to 250℃ makes it suitable for various applications.

Properties of Large Diameter Silicone Tubing

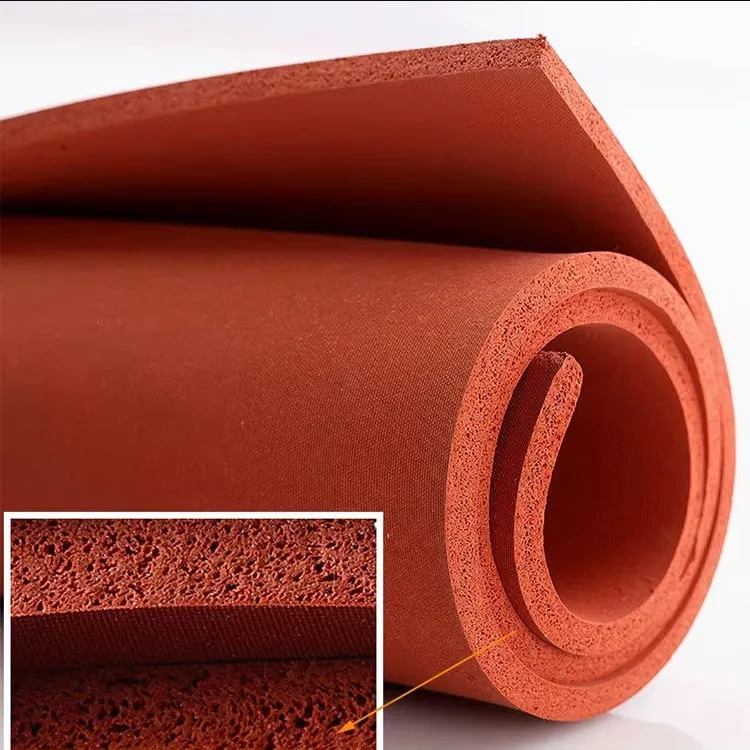

Silicone as a material

Silicone tubing is made from silicone rubber, a synthetic elastomer known for its flexibility and resilience. This material exhibits excellent thermal stability, maintaining its properties across a wide temperature range from -60℃ to 350℃. Silicone rubber's inherent biocompatibility makes it suitable for medical and pharmaceutical applications. The material's non-reactive nature ensures compatibility with various chemicals, enhancing its utility in diverse industrial settings.

Additives and enhancements

Manufacturers often incorporate additives to enhance the properties of silicone tubing. These additives can improve characteristics such as tear strength, elongation capacity, and resistance to environmental factors. For example, adding platinum can increase the tubing's durability and reduce the risk of contamination. Other enhancements might include colorants for easy identification or surface treatments to reduce friction and improve flow characteristics.

Flexibility and durability

Large diameter silicone tubing offers exceptional flexibility, allowing it to bend and stretch without losing its shape. This flexibility is crucial for applications requiring frequent movement or adjustments. The tubing also boasts high tear strength, with values reaching up to 25 Mpa, ensuring long-lasting performance even under stress.

Temperature resistance

Silicone tubing excels in extreme temperature conditions. It can withstand temperatures as low as -60℃ and as high as 350℃. This broad temperature range makes it ideal for applications in environments with fluctuating temperatures, such as automotive engines or industrial ovens.

Chemical resistance

The chemical resistance of silicone tubing makes it suitable for handling a variety of substances. It remains unaffected by most acids, bases, and solvents, ensuring safe and reliable performance in chemical processing and pharmaceutical manufacturing. This resistance also extends to UV light and ozone, further enhancing the tubing's longevity.

Customizable properties

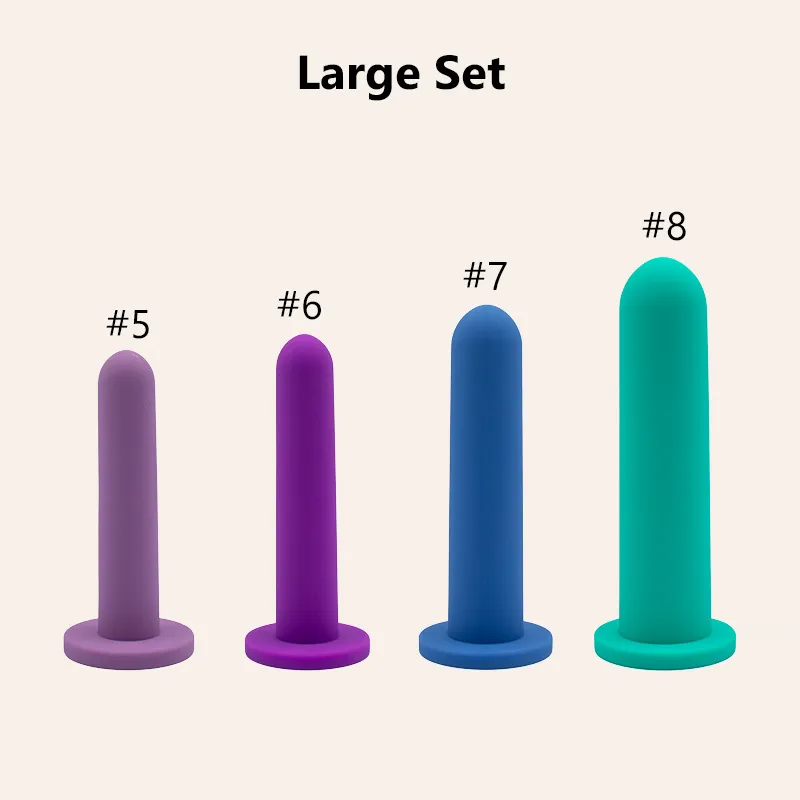

Manufacturers offer extensive customization options for silicone tubing. Customization includes variations in color, texture, and size. Businesses can select smooth, wave, or braided surfaces based on specific needs. Custom properties enhance the tubing's functionality, making it suitable for specialized applications. For instance, research labs reported improved sample integrity after switching to customized silicone tubing.

Manufacturing Process of Large-diameter Silicone Tube

Extrusion process

The extrusion process involves forcing silicone rubber through a die to create tubing with precise dimensions. This method ensures consistent wall thickness and diameter, critical for maintaining the tubing's performance characteristics. Advanced extrusion techniques allow for the production of large diameter silicone tubing with smooth or textured surfaces, depending on the application requirements.

Applications of Large Diameter Silicone Tubing

Uses in medical devices

Large diameter silicone tubing plays a crucial role in medical devices. Manufacturers use this tubing in applications such as catheters, drainage systems, and respiratory equipment. The biocompatibility of silicone tubing ensures patient safety and reduces the risk of adverse reactions. For instance, a pharmaceutical company utilized custom-designed silicone tubing in a novel drug delivery system, resulting in increased efficiency and patient safety.

Uses in manufacturing and processing

In industrial settings, large diameter silicone tubing finds applications in manufacturing and processing. Industries use this tubing for fluid transfer, chemical processing, and pneumatic systems. The flexibility and durability of silicone tubing make it ideal for environments requiring frequent movement and adjustments. A biotech firm incorporated silicone tubing in their bioreactors, enhancing the cultivation process of microbial cultures with improved sterility and temperature control.

Uses in food and beverage industry

The food and beverage industry benefits significantly from large diameter silicone tubing. This tubing is used for transferring liquids, such as juices, dairy products, and alcoholic beverages. The non-toxic and hypoallergenic properties of silicone tubing ensure that the transferred substances remain uncontaminated. The tubing's ability to withstand high temperatures makes it suitable for processes like pasteurization and sterilization.