As a custom silicone manufacturer with over 20 years of experience and 10000 successful custom silicone mold openings, JESilicone provides high quality custom extruded and molded products for a broad range of industries including medical, food & beverage, electronics, automotive, and more.

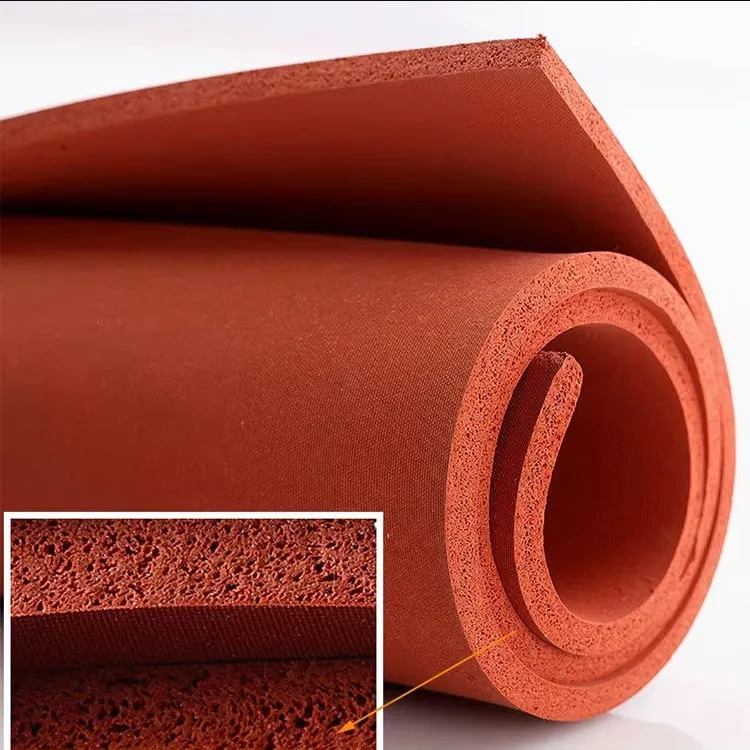

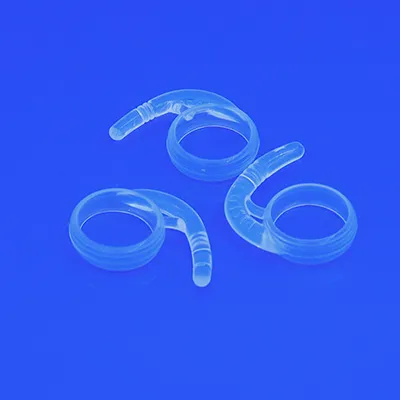

Our custom silicone product range includes silicone extrusion tubing, silicone sleeves, silicone cases, silicone sheets, silicone gaskets, silicone grommets, silicone o-rings, silicone seals, LSR parts, and other customized silicone parts. From simple seals to the most complex silicone parts, we utilize a host of sophisticated technologies and processes to consistently manufacture high-quality silicone parts to meet your applications‘s demand.

No matter what type of silicone product you’re looking for, our experienced engineers will work with you to determine the best compound and manufacturing method.

INQUIRY NOW >>

Industries We Serve

JESilicone supplies a wide range of custom Silicone Rubber parts and LSR injection molded components. These components can be found in products used in a wide array of industries, including medical & healthcare, consumer goods, food & beverage, automotive, mobility, electronics, sanitary, and industrial and special applications.

Let a JESilicone expert offer you solutions that will help optimize your design, meet your high-quality & high-volume demand for precision silicone injection molded components, and add value every step of the way.

INQUIRY NOW >>

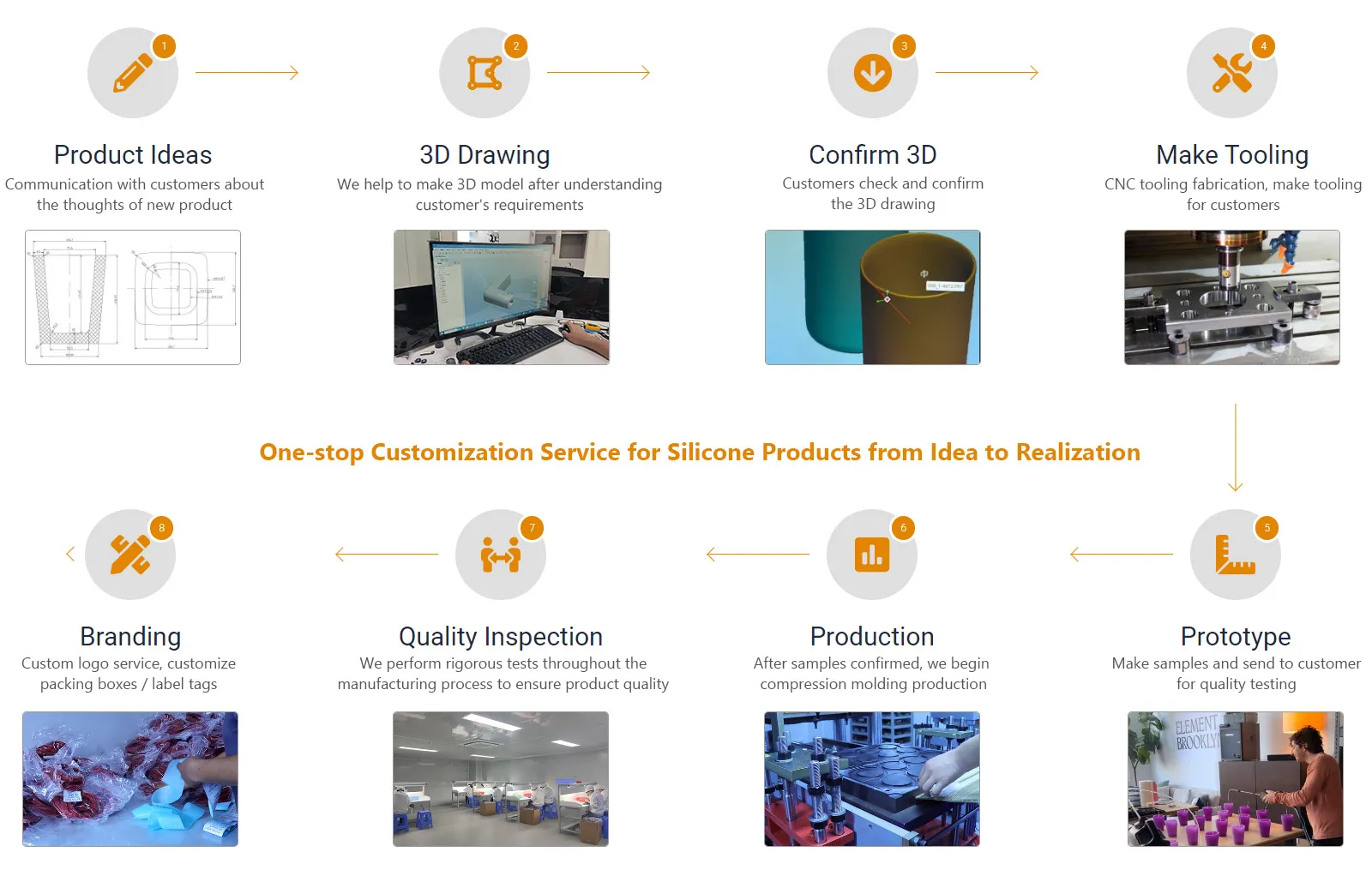

HOW TO CUSTOMIZED SILICONE PRODUCTS | CUSTOM SERVICE PROCESS

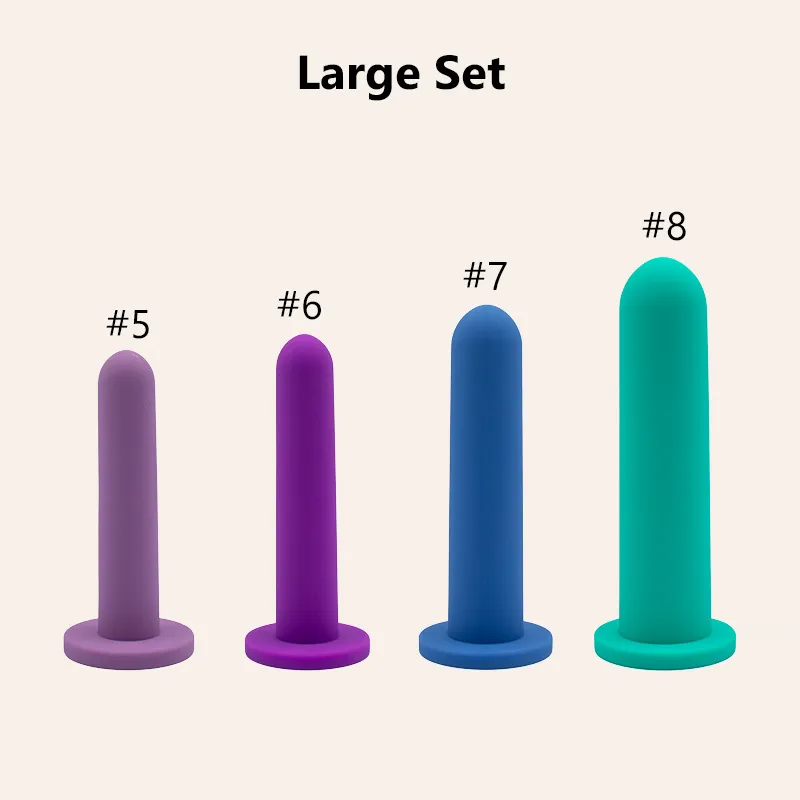

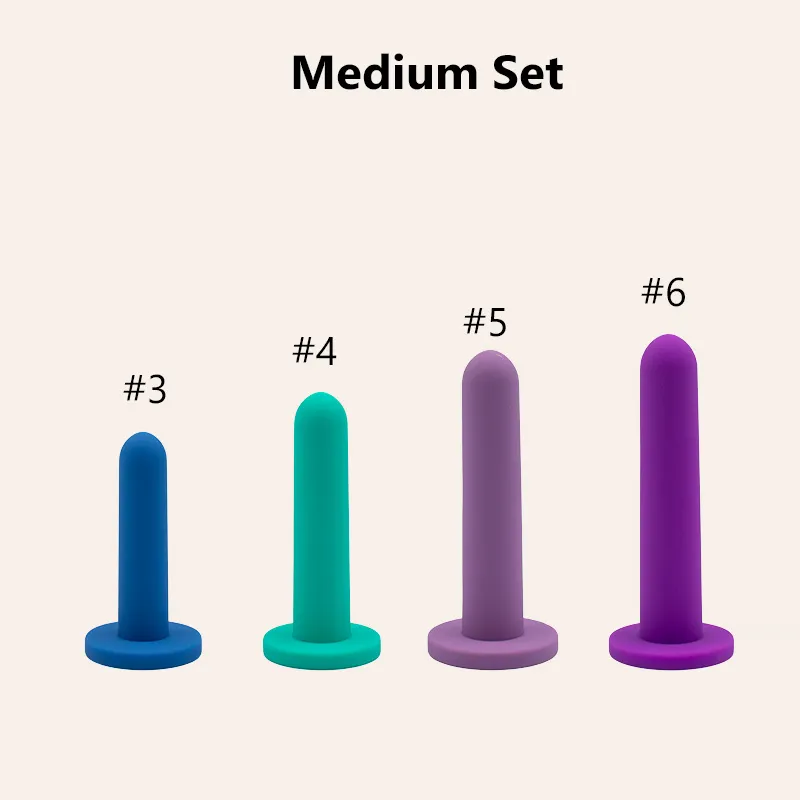

We offer a wide range of customization options, including: material, shapes, surfaces, size, colors, hardness, logo, package, etc.

OUR CAPABILITIES

We specialize in designing, developing, and producing high-quality custom parts that meet your exact specifications.

Product Design Service

If our customer can’t offer 3D drawing, our engineer team will help to build the 3D files when we receive detailed product requirements from customer.

Our highly skilled engineers collaborate closely with customers during the initial stages of designing customized silicone parts. Through effective communication, we work together to develop 3D files based on the finalized design, ensuring a mutual agreement is reached. The 2D or 3D CAD modeling is then shared with the customer for thorough review, providing an opportunity to identify any areas that may require revisions.

INQUIRY NOW >>

Prototype & Compression Molding & Manufactring

After the drawings and designs are confirmed, we will develop the molds to build prototypes. The purpose is to verify and assist the customer in understanding the product’s characteristics.

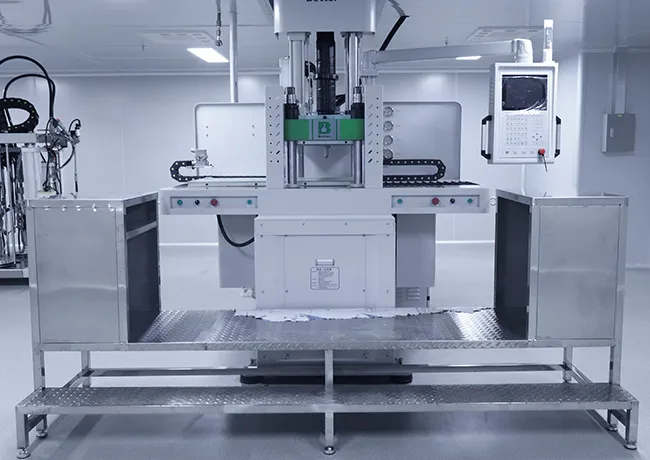

Our facility is equipped with more than 10 sets of professional vulcanization equipment to produce various molded silicone products.

Silicone compression molding is a common manufacturing technique used to transform uncured / unvulcanized silicone rubber into a pre-defined shape, the uncured silicone rubber material will be placed between two halves of a pre-heated tool mold.

The mold is then closed under a top force from the vulcanizer molding machine. The high pressure will force the silicone material into contact with all areas of the mold cavity.

The heat and pressure will last for a few minutes until the raw material is fully cured, so this process is also known as silicone vulcanization.

INQUIRY NOW >>

LSR Injection Molding

We offer complete turnkey solutions for all business in need of high quality liquid silicone rubber injection molded parts (LSR molded parts).

Our facility is equipped with state-of-the-art liquid injection molding (LIM) cells with inline vision technology, value-added operations stations and finely tuned quality systems – all of which ensure we deliver high-quality, high-volume LSR parts to our customers.

INQUIRY NOW >>

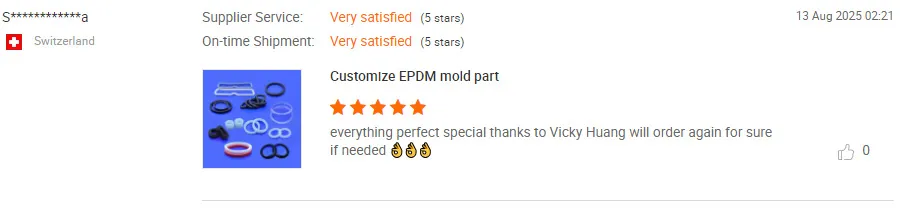

WHAT OUR CLIENTS SAY

Our customers are very pleased with the precision, timeliness, and product quality of our custom silicone products..

Contact Us

Thank you very much for considering JESilicone Company. Thank you for your trust in our service!

Usually, we provide 1 working day for quotation, 7 days for sample, 2 weeks for mass production.

To get a quick and exact quote for custom silicone products, please fill out this standard contact form, this will help us respond to your request faster.