China's Leading Manufacturer of Silicone Parts

JESilicone provides one-stop custom service of silicone parts for a broad range of industries including medical, automotive, food, electronics, and more. Our company has over 20 years of experience with more than 10,000 successful customized silicone mold openings. Our custom silicone parts process includes product design, material selection, silicone mixing & cutting, silicone mold making & prototype, production, quality inspection, packaging, labeling, and shipping.

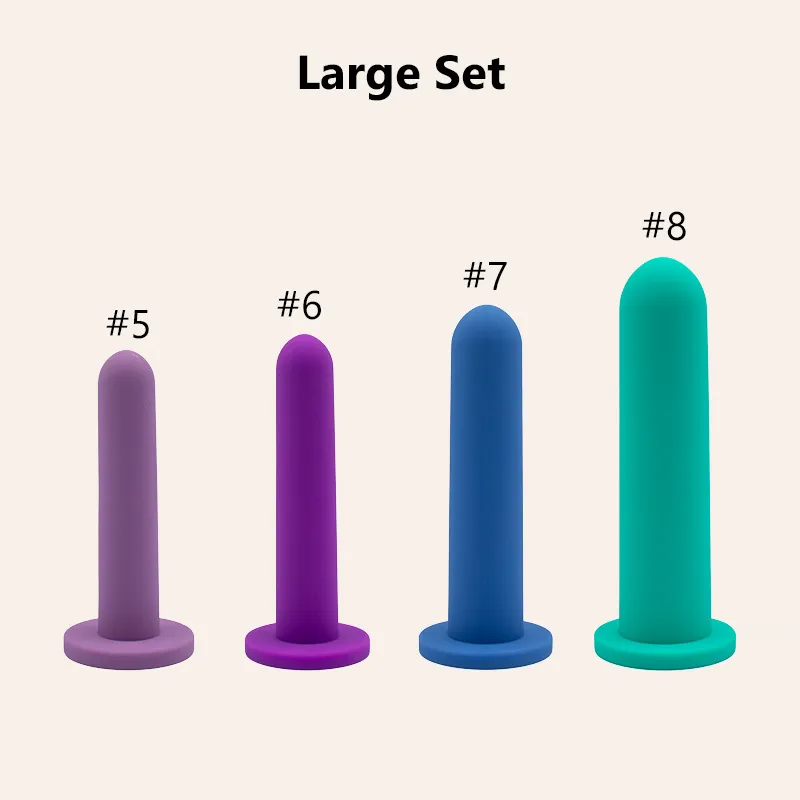

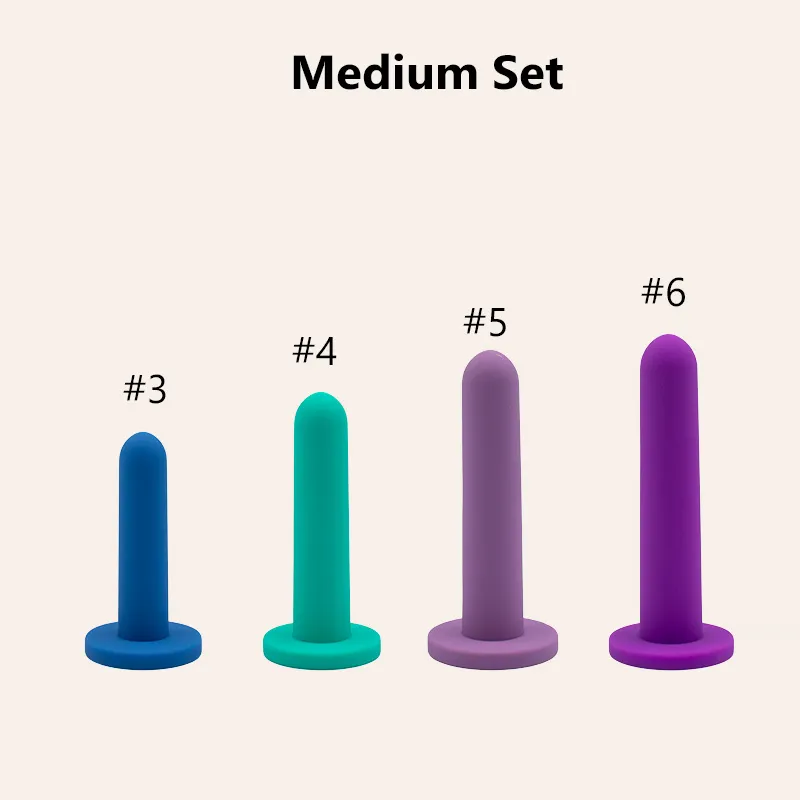

Customization options include product shape, size, color, hardness, logo, package, label, and so on.

JESilicone provides industry-leading custom extruded and molded products. From simple sleeves to the most complex silicone parts, we utilize a host of sophisticated technologies and processes to consistently manufacture high-quality silicone parts to meet your applications demand.

Our team of experts has decades of knowledge and experience in compression molding and LSR injection molding. Our state-of-the-art production facilities are fully equipped with modern equipment and use the latest technologies. Since we have so many successful mold opening cases, we can manufacture your custom rubber molding components efficiently and economically, while meeting the highest quality standards. No matter what type of silicone part you’re looking for, our engineers will work with you to determine the best compound and manufacturing method. Call us or send an email to us so we can collaborate and provide solution for your project.

Silicone Parts Manufacturing Process

1. Material Selection

Criteria For Choosing Silicone

Selecting the right silicone material is crucial for manufacturing high-quality silicone parts. The choice depends on several factors:

- Application Requirements: Consider the specific use of the part, such as medical devices, automotive components, or kitchenware.

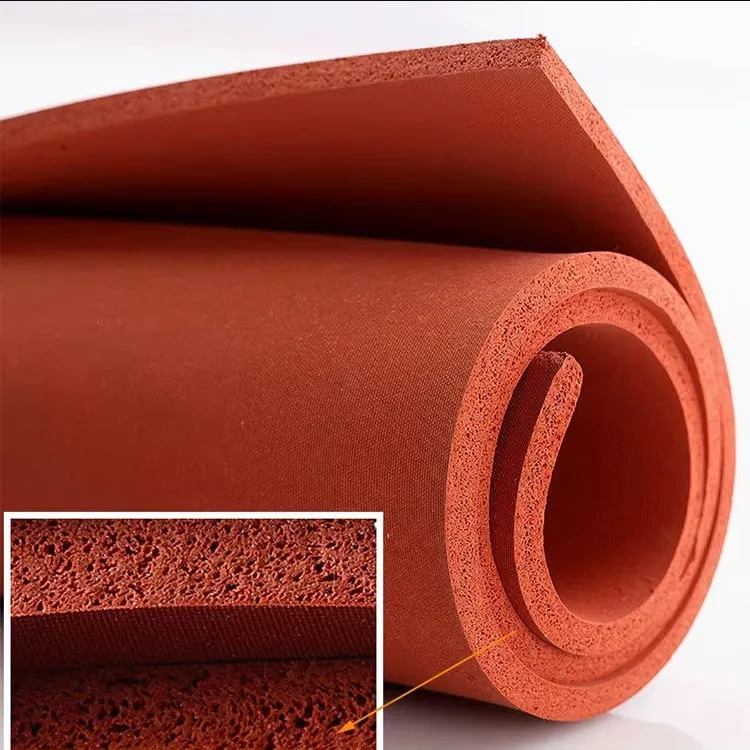

- Type of Silicone: Choose between Liquid Silicone Rubber (LSR) and High Consistency Rubber (HCR). LSR offers excellent thermal stability and flexibility, while HCR provides enhanced mechanical strength.

- Durometer (Hardness): Select the appropriate hardness level to ensure optimal performance and durability.

- Color: Decide on color based on aesthetic requirements or functional needs.

Common Additives And Fillers

Additives and fillers enhance the properties of silicone materials. Common options include:

- Silica Fillers: Improve mechanical strength and thermal stability.

- Pigments: Provide color customization for aesthetic purposes.

- Flame Retardants: Enhance fire resistance for safety-critical applications.

2. Mold Design And Fabrication

Types Of Molds

Different types of molds are used in silicone parts manufacturing:

- Single-Cavity Molds: Suitable for low-volume production with simple designs.

- Multi-Cavity Molds: Ideal for high-volume production, reducing cycle time per part.

- Family Molds: Produce multiple different parts in one molding cycle.

Mold Making Techniques

Several techniques are employed to create molds:

- CNC Machining: Provides high precision and accuracy in mold fabrication.

- Electrical Discharge Machining (EDM): Used for intricate mold designs requiring fine details.

- 3D Printing: Offers rapid prototyping capabilities, allowing quick iterations during design phases.

3.Post-Processing

Curing And Vulcanization

Curing and vulcanization are essential steps in the manufacturing of silicone parts. These processes involve applying heat to the silicone material, which facilitates cross-linking between polymer chains. This cross-linking enhances the mechanical properties and stability of the final product.

- Curing Methods: The two primary curing methods include thermal curing and platinum-catalyzed curing. Thermal curing uses elevated temperatures to initiate the reaction, while platinum-catalyzed curing employs a platinum catalyst for room temperature or low-temperature curing.

- Vulcanization Process: Vulcanization typically involves heating silicone rubber with sulfur or other curatives. This process improves elasticity, strength, and resistance to environmental factors.

Trimming And Finishing

Trimming and finishing ensure that silicone parts meet precise specifications and aesthetic standards. These steps remove excess material, flash, or imperfections resulting from the molding process.

- Trimming Techniques: Manual trimming using knives or scissors is common for small production runs. Automated trimming machines provide higher efficiency for large-scale operations.

- Finishing Processes: Surface treatments such as sanding, buffing, or coating enhance the appearance and functionality of silicone products. These processes can also improve surface smoothness and reduce friction.

Quality Control And Testing

Quality control ensures that manufactured silicone parts meet industry standards and customer requirements. Rigorous testing identifies defects early in the production cycle, minimizing waste and ensuring consistent quality.

- Dimensional Inspection: Measuring tools such as calipers, micrometers, and coordinate measuring machines (CMM) verify dimensional accuracy.

- Mechanical Testing: Tests like tensile strength, elongation at break, hardness (durometer), and tear resistance assess mechanical properties.

- Environmental Testing: Exposure to extreme temperatures, UV light, chemicals, or humidity evaluates durability under various conditions.

Pinch Testing

Pinch testing determines the quality of silicone products by assessing their composition. This test involves pinching a section of the silicone part to observe any color change indicating plastic fillers’ presence.

- Procedure: Apply pressure to a small area of the part using fingers or specialized tools.

- Interpretation: A noticeable color change suggests contamination with plastic fillers; no color change indicates pure silicone material.

What Are The Applications of Silicone Parts?

The following are part of common applications of silicone molded parts:

Medical Devices

Silicone parts play a critical role in the medical industry. Manufacturers use silicone to produce various medical devices due to its biocompatibility and flexibility. Examples include catheters, tubing, and respiratory masks. These devices require materials that can withstand sterilization processes without degrading.

Implants

Silicone is also used for implants. The material’s non-reactive nature makes it suitable for long-term implantation in the human body. Common applications include breast implants, joint replacements, and heart valves. These implants benefit from silicone’s durability and ability to mimic natural tissue properties.

Seals And Gaskets

Silicone parts are essential for creating seals and gaskets. These components must endure extreme temperatures and exposure to oils and chemicals. Silicone’s temperature resistance ensures reliable performance under harsh conditions.

Hoses And Tubing

Automotive manufacturers also use silicone for hoses and tubing. These parts need flexibility and strength to handle high-pressure fluids within engines. Silicone provides excellent thermal stability, making it ideal for coolant hoses, turbocharger hoses, and vacuum lines.

Insulation Components

Silicone is used in insulation components within aircraft systems too. The material offers excellent electrical insulation properties while resisting fire hazards. This makes silicone suitable for insulating wires, cables, and other electronic components in aerospace applications.

Kitchenware

Silicone parts have revolutionized the kitchenware industry. Manufacturers prefer silicone for its non-stick properties and heat resistance. Silicone baking mats, spatulas, and molds withstand high temperatures without degrading. These products do not retain odors or flavors, ensuring food safety.

Electronics

The electronics industry benefits significantly from silicone parts due to their insulating properties. Silicone provides excellent electrical insulation, making it ideal for protecting electronic components.

Any Requirement About Custom Silicone Parts? Our engineers are here to help you.

Please feel free to leave your message. Our experienced engineers will reply to you as soon as possible.