What Silicone Molded Parts We Can Make

| Silicone Tubes |

Silicone Hoses |

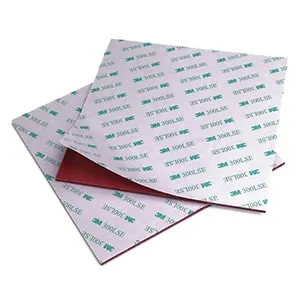

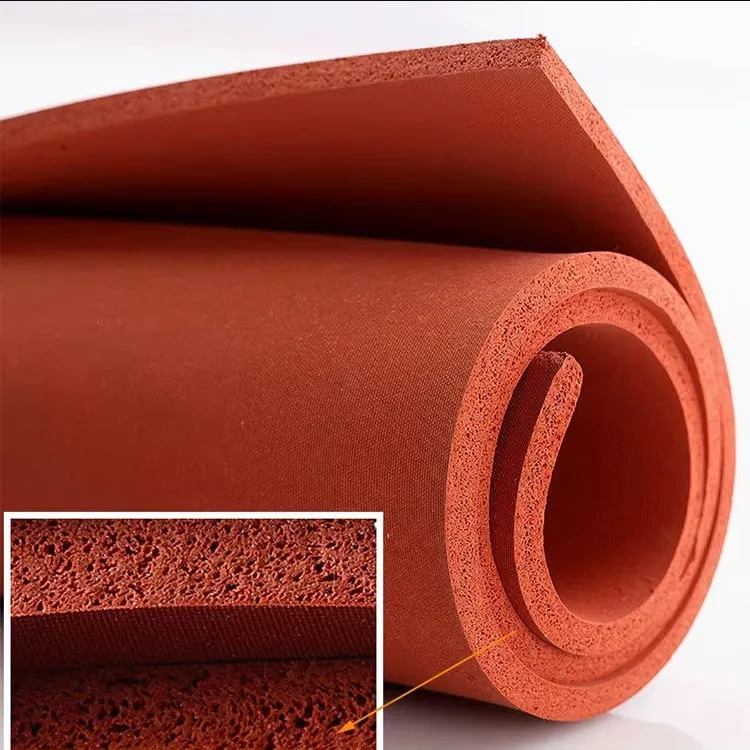

Silicone Sheets |

Silicone Seals |

| Silicone Sleeves |

Silicone Covers |

Silicone Cases |

Silicone Gaskets |

| Silicone Grommets |

Silicone Rings |

Silicone Orings |

Silicone Strips |

| Silicone Balls |

Silicone Pads |

Silicone Wheels |

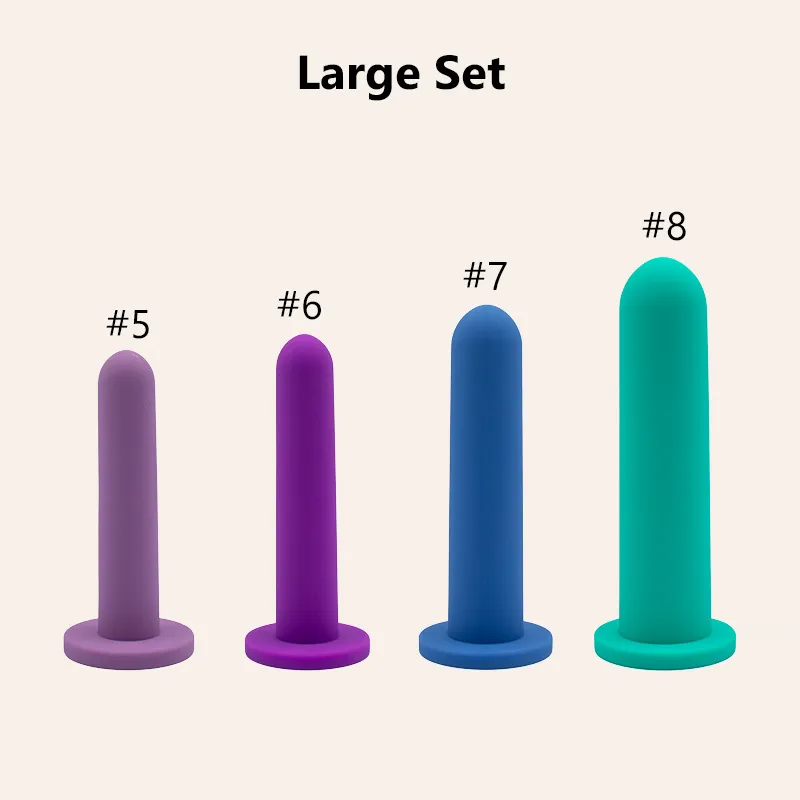

Silicone Toys |

| Silicone Plugs |

Silicone Washes |

Silicone Rollers |

Silicone Protectors |

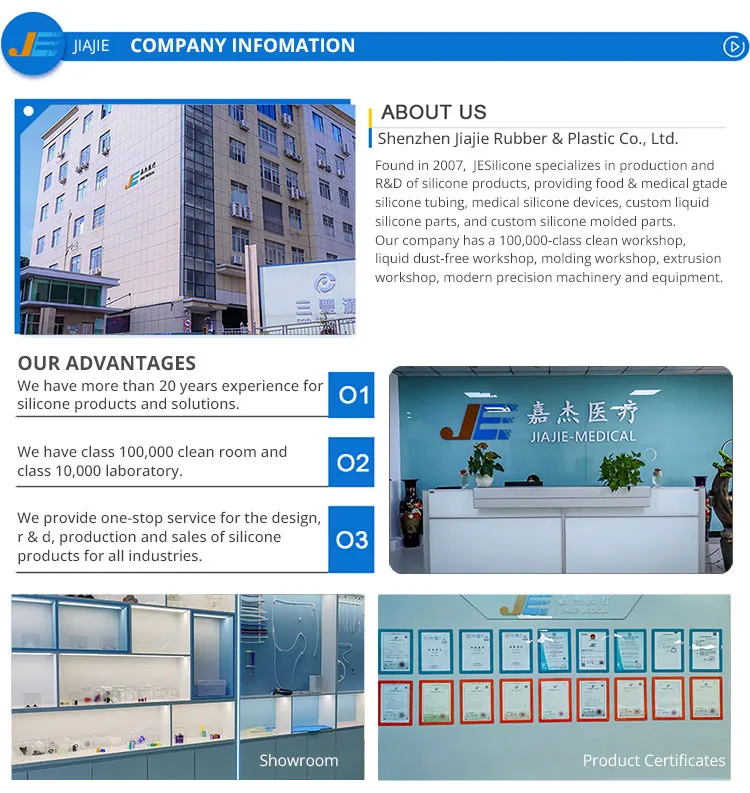

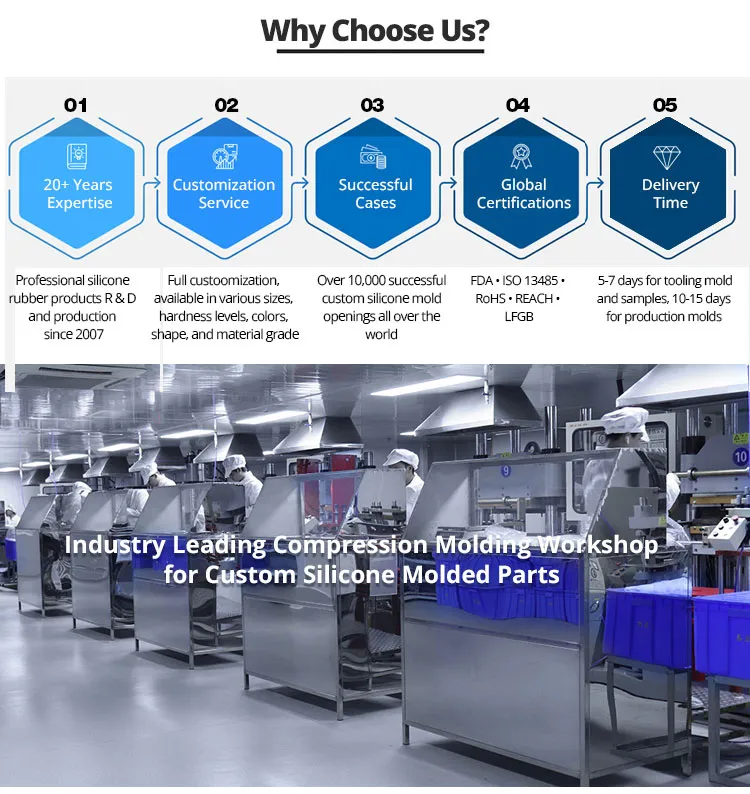

Why Choose JE Silicone As Your Custom Silicone Parts Supplier?

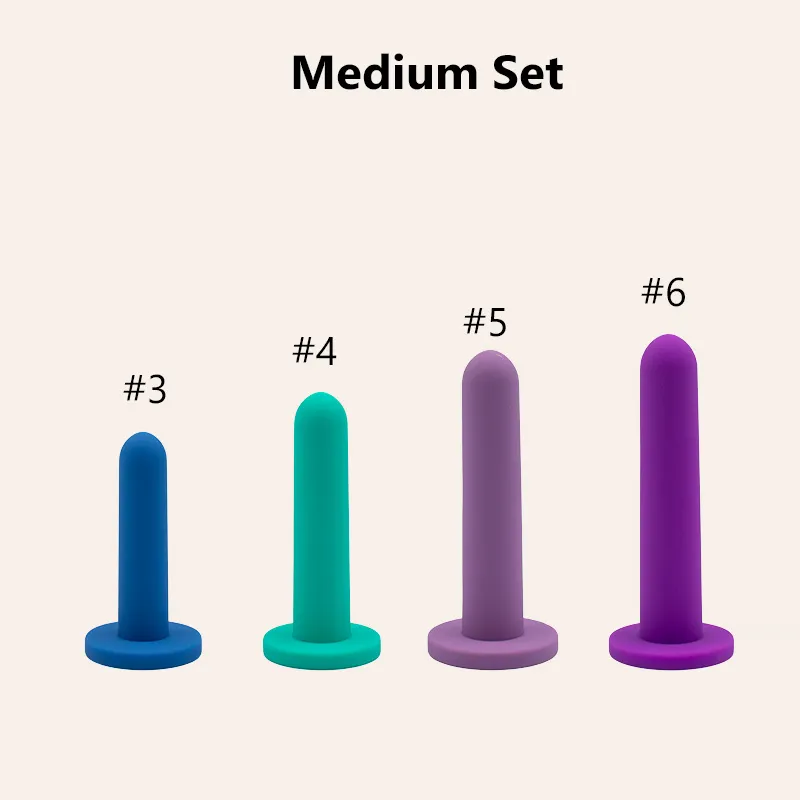

- Customizable Design: Our custom silicone rubber parts are designed to meet your specific needs, allowing you customize the shapes, sizes, colors, silicone material grade, and hardness levels (10-80 Shore A) to suit your application.

- Wide Applications: Our silicone parts are suitable for use in all industries, making them a versatile solution for various machinery and equipment applications.

- Competitive Pricing: We offer a competitive price for our custom silicone / EPDM / NBR molded rubber parts, ensuring

you get high-quality products at an affordable cost.

- Flexible MOQ: No MOQ required, we cater to both small and large-scale businesses, making it ideal for users such as "small businesses" or "startups" looking to test the market.

- Quick Sample Time: 5-7 days for sample tooling, enable you to receive your custom rubber parts quickly, allowing you to speed up your production process and stay ahead of the competition.

Successful Cases Show

JE Silicone has 10,000+ successful custom silicone mold openings for a broad range of industries including medical, food & beverage, electronics, automotive and more.

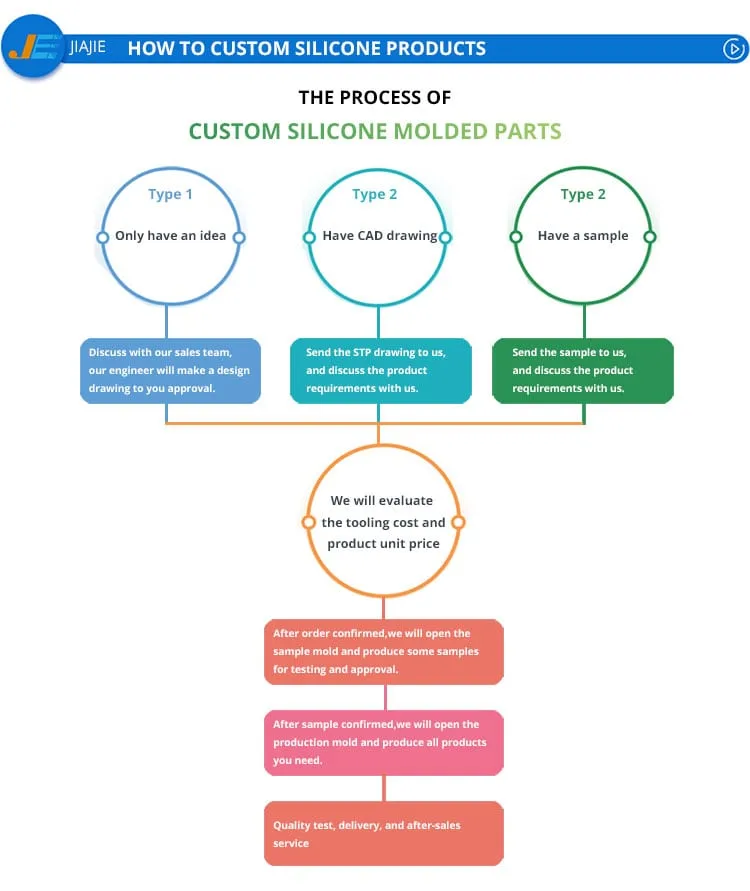

The Complete Process of Custom Silicone Parts Manufacturing

With over 20 years of expertise and 10,000+ successful molding projects, our process combines technical precision with industry-leading efficiency. Below is a detailed breakdown of the custom silicone parts production journey:

1. Requirement Analysis & Design Consultation

The process begins with an in-depth discussion to clarify your specifications:

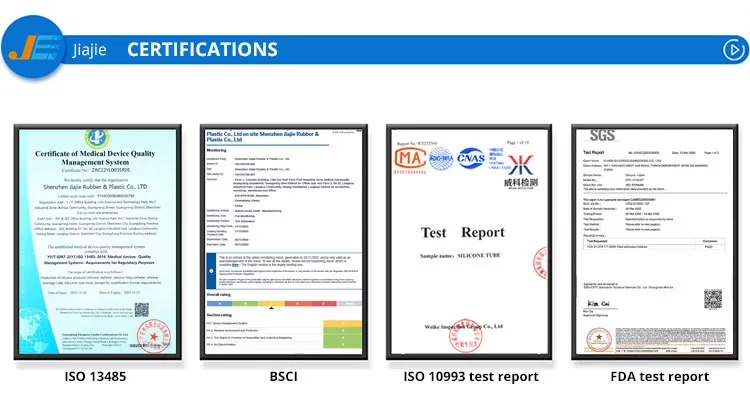

- Functional Needs: Temperature resistance, flexibility, certifications (FDA, LFGB, ROHS, etc.)

- Design Inputs: CAD files, 3D models, or hand-drawn sketches

- Usage Context: Medical, automotive, food contact, or industrial applications

2. Material Selection & Verification

Silicone compounds are chosen based on operational demands, we will consider hardness, color, and compliance, We provide material test reports (TDS, MSDS) and physical samples for approval.

3. Precision Mold Development

Mold fabrication follows a rigorous 4-step protocol:

- 3D Modeling: Create CNC-compatible tooling designs

- Prototype Tooling: Test with LSR (Liquid Silicone Rubber) or HCR (High-Consistency Rubber)

- Trial Runs: Produce 5–10 samples for dimensional verification

- Final Adjustments: Modify gate positions and cooling channels

- Typical lead time: 10–15 days | Tolerance: ±0.05mm

4. Prototyping & Functional Testing

- Pre-production prototypes undergo critical evaluations:

- Dimensional Accuracy: CMM (Coordinate Measuring Machine) inspection

- Mechanical Testing: Tensile strength, elongation, tear resistance

- Environmental Simulation: Aging, UV exposure, and chemical resistance tests

5. Mass Production

Upon prototype sign-off, full-scale manufacturing commences:

- Molding Techniques: LSR injection, compression, or extrusion molding

- In-Process QC: Real-time monitoring of pressure (150–200 MPa) and temperature (120–200°C)

- Post-Processing: Deburring, surface texturing, or secondary bonding

6. Comprehensive Quality Assurance

A three-tier inspection system ensures reliability:

- Visual Check: Surface defects, flash, or discoloration

- Dimensional Audit: 100% critical dimension verification

- Performance Validation: Leakage tests, compression set analysis

7. Logistics & After-Sales Support

- Packaging: Vacuum-sealed anti-contamination bags

- Shipping: FCL/LCL options with DDP/DAP incoterms

- Post-Delivery: 24-month tooling warranty, technical troubleshooting