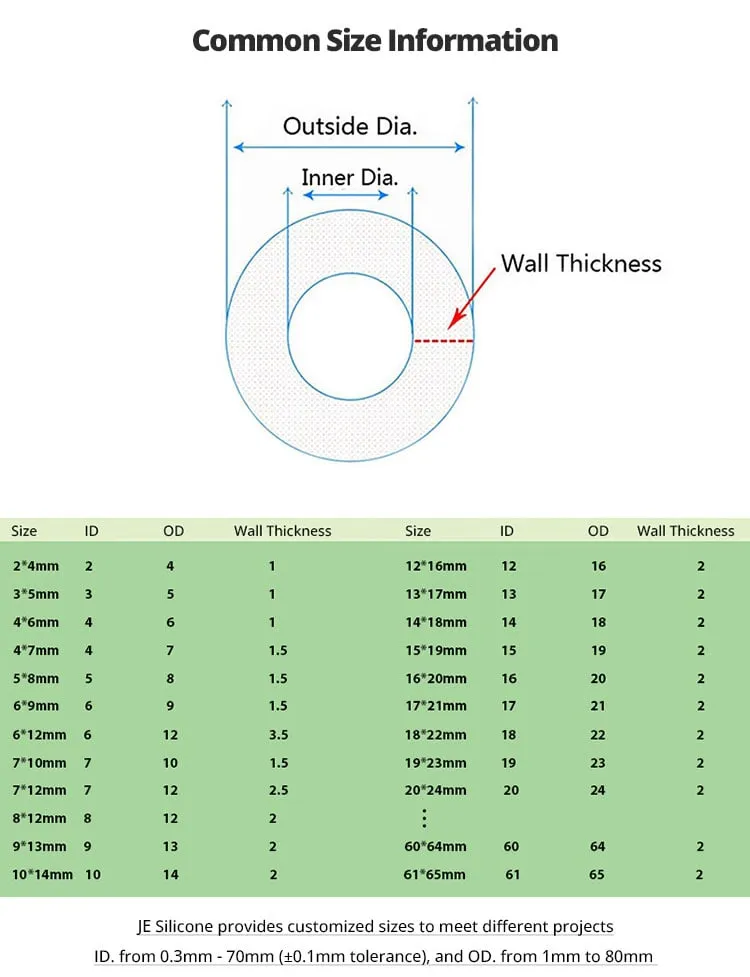

List of Common Thin Wall Silicone Tubing We Provide

|

Inner Diameter (ID) |

Outer Diameter (OD) |

Wall Thickness |

Color |

|

1/16" |

1/8" |

1/32" |

Clear, or Pantone color |

|

1/8" |

3/16" |

1/32" |

Clear, or Pantone color |

|

3/8" |

9/16" |

3/32" |

Clear, or Pantone color |

|

3/16" |

3/8" |

3/32" |

Clear, or Pantone color |

|

3/16" |

5/16" |

1/16" |

Clear, or Pantone color |

|

5/8" |

3/4" |

1/16" |

Clear, or Pantone color |

|

1/12" |

1/4" |

1/12" |

Clear, or Pantone color |

|

1/64" |

1/16" |

3/128" |

Clear, or Pantone color |

|

1/2" |

5/8" |

1/16" |

Clear, or Pantone color |

|

1/2" |

9/16" |

1/32" |

Clear, or Pantone color |

|

1/4" |

1/2" |

1/8" |

Clear, or Pantone color |

|

1/4" |

3/8" |

1/16" |

Clear, or Pantone color |

|

3/8" |

1/2" |

1/16" |

Clear, or Pantone color |

|

5/16" |

1/2" |

3/32" |

Clear, or Pantone color |

|

5/16" |

7/16" |

1/16" |

Clear, or Pantone color |

|

Customized |

Customized |

(OD-ID)/2 |

Clear, or Pantone color |

Why Our Thin Wall Silicone Tubing Stands Out

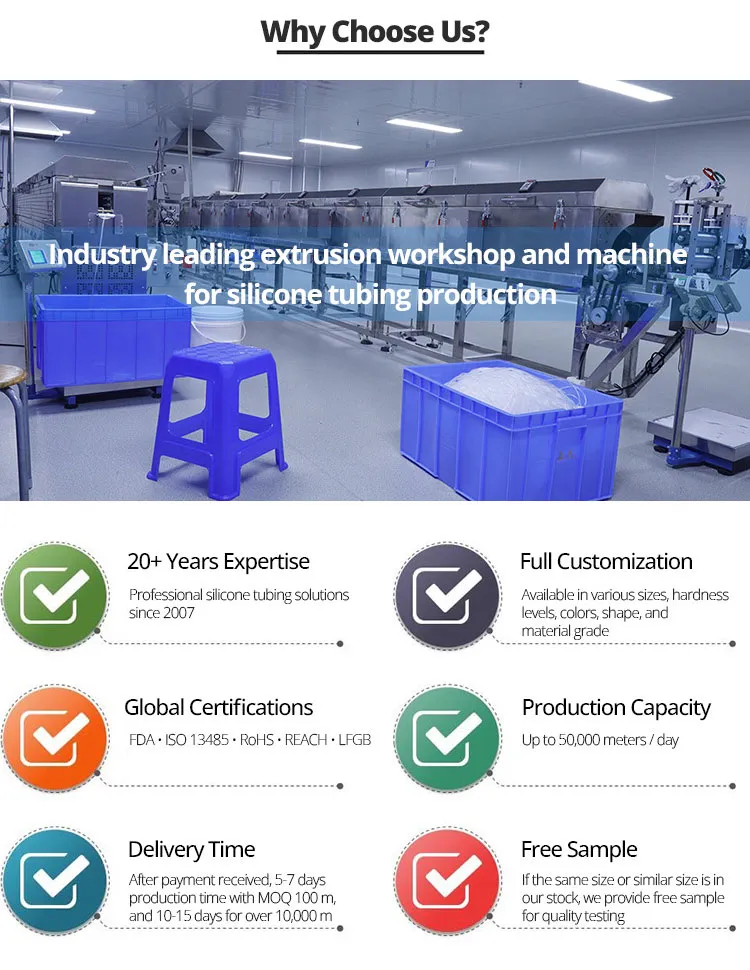

1. Precision Manufacturing: Each silicone tube is produced under strict quality control standards, ensuring it meets the specifications of your unique needs. We utilize state-of-the-art equipment and techniques to produce consistent, high-quality tubing every time.

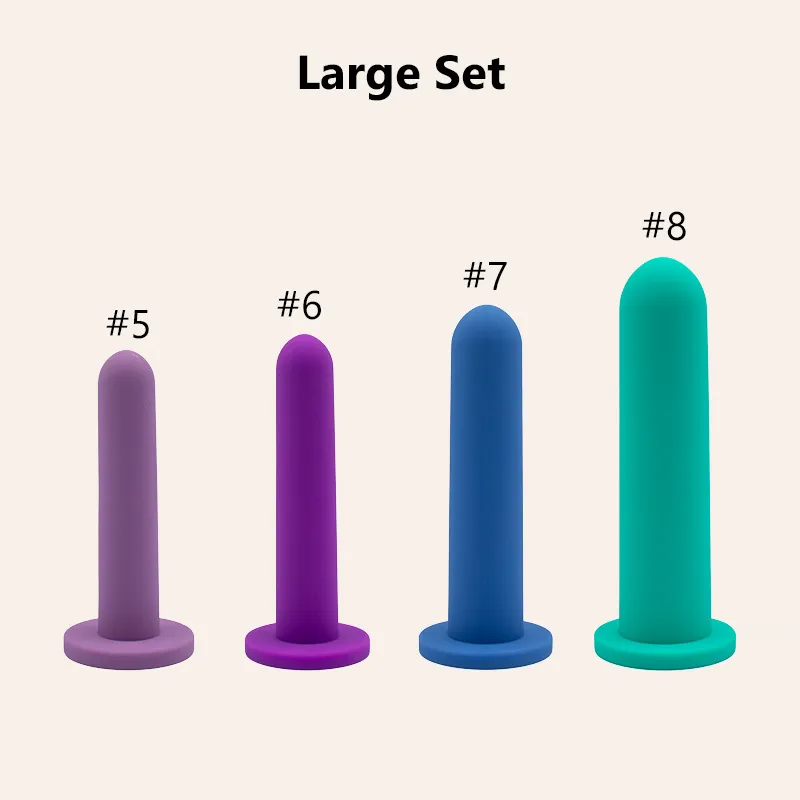

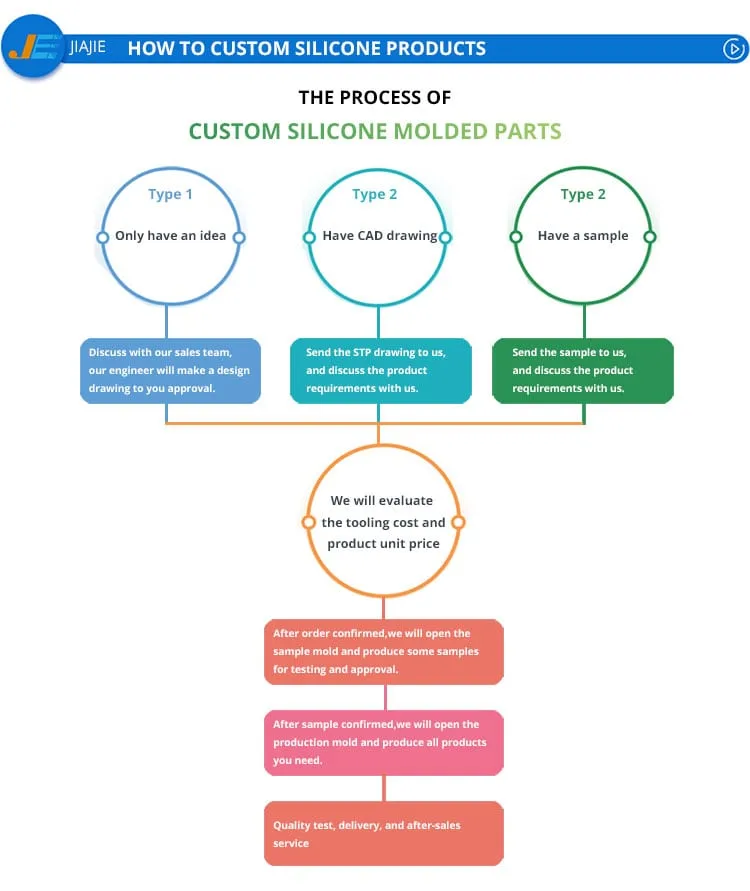

2. Custom Sizing: We offer a range of standard sizes, but we can also customize the diameter, length, and wall thickness of the tube to meet your exact requirements.

3. Global Shipping: We provide fast and reliable shipping options to customers worldwide. Whether you’re in North America, Europe, Asia, or beyond, you can count on timely delivery of your order.

4. Customer Support: Our expert customer support team is here to assist you with any questions or concerns. Whether you need technical advice or assistance with placing an order, we’re here to help.

What’s Thin Wall Silicone Tubing

Thin wall silicone tubing is a specialized type of tubing made from high-quality silicone rubber. It features an ultra-thin wall thickness, often as low as 0.25mm, which makes it lightweight and highly flexible. This tubing is designed to perform in demanding environments, offering exceptional durability and resistance to extreme temperatures, chemicals, and environmental factors. Its unique properties make it a preferred choice for industries requiring precision and reliability.

Unlike traditional tubing, thin-wall silicone tubing provides a balance of flexibility and strength. It is non-toxic, odorless, and does not release harmful fumes, ensuring safety in sensitive applications. Manufacturers often customize this tubing to meet specific requirements, such as varying diameters, wall thicknesses, and hardness levels, making it versatile across multiple industries.

Various industries, such as medical, manufacturing, food and beverage, laboratory, and scientific research, rely on this tubing for its unique properties. The medical field uses it in catheters, feeding tubes, and drainage devices. Manufacturing employs it for conduits for transferring fluids, gases, and electrical wiring. Food and beverage sectors utilize it for transferring liquids. Laboratories use it for fluid transfer and chromatography. Key properties of this tube include chemical inertness, biocompatibility, flexibility, temperature resistance, and sterilizability.

Relate Article: Thin Wall Silicone Tubing VS. Traditional Tubing

Basic Characteristics of Thin Wall Silicone Tubing

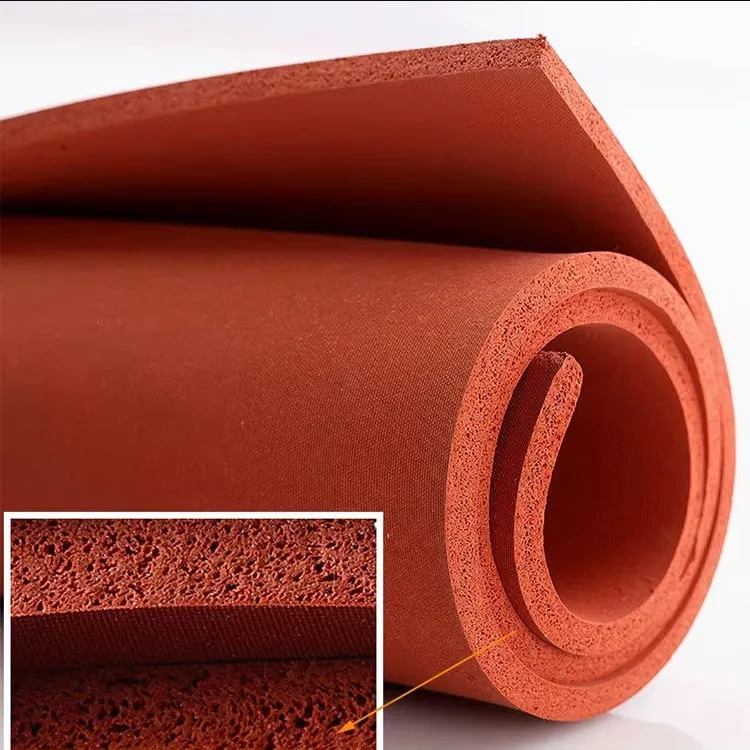

Silicone as a base material

Thin wall silicone tubing uses silicone elastomers as the primary material. Silicone, a synthetic polymer, consists of silicon, oxygen, carbon, and hydrogen. This composition provides exceptional flexibility and temperature resistance. The biocompatibility of silicone makes it suitable for medical and food applications.

Additives and their roles

Manufacturers often incorporate additives into thin wall silicone tubing to enhance specific properties. These additives can improve flexibility, durability, and chemical resistance. For instance, some additives increase the tubing’s resistance to ultraviolet (UV) light, extending its lifespan in outdoor applications.

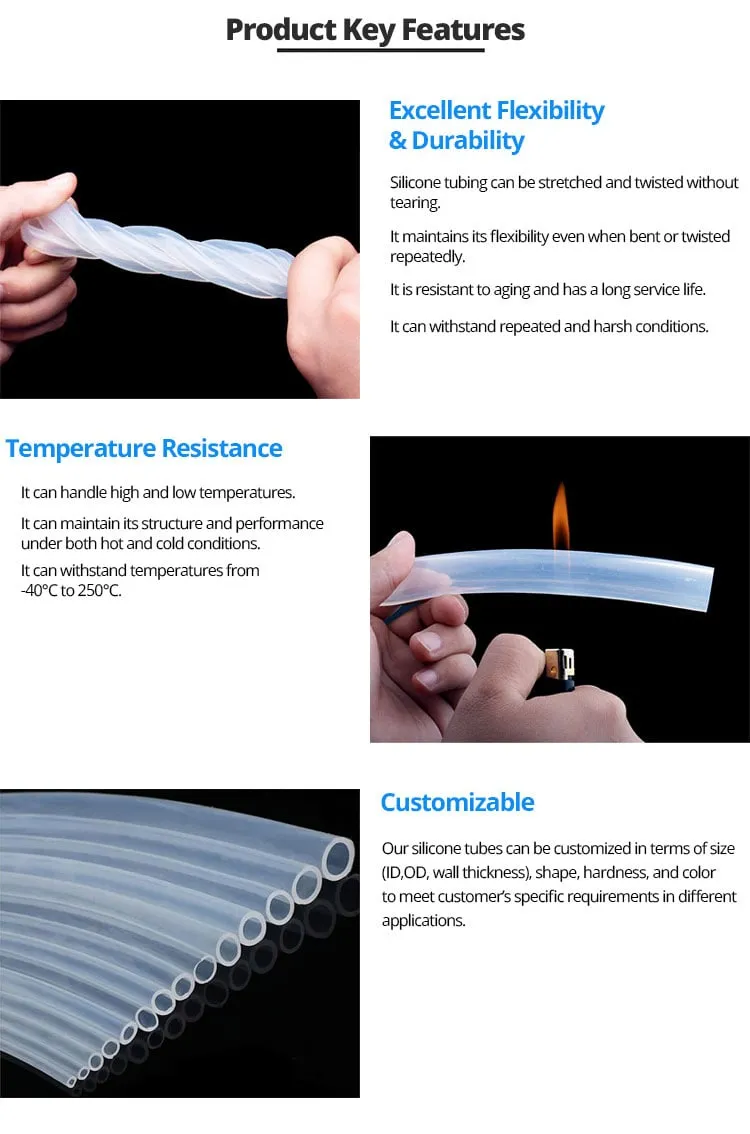

Flexibility and elasticity

Thin wall silicone tubing offers remarkable flexibility and elasticity. This property allows the tubing to bend and stretch without breaking. The thin walls provide flexibility without compromising strength. This makes the tubing ideal for complex designs and tight spaces.

Temperature resistance

Thin wall silicone tubing exhibits excellent temperature resistance. The material can withstand extreme temperatures ranging from -40°C to 250°C. This makes the tubing suitable for various applications, including those involving high heat or cold environments. The tubing maintains its properties even after repeated exposure to these conditions.

Durability and longevity

Thin wall silicone tubing boasts impressive durability and longevity. The material resists wear and tear, ensuring a long service life. The tubing can endure harsh conditions, including exposure to chemicals, UV light, and mechanical stress. This durability reduces the need for frequent replacements, offering long-term cost efficiency.

Applications of Ultra Thin Wall Silicone Tubing

Uses in medical devices

Thin wall silicone tubing plays a vital role in the medical industry. Manufacturers use this tubing in catheters, feeding tubes, and respiratory devices. The biocompatibility of thin wall silicone tubing ensures safe contact with bodily fluids and tissues. The flexibility of the tubing allows for easy insertion and maneuverability within the human body.

Benefits in healthcare applications

Thin wall silicone tubing offers numerous benefits in healthcare settings. The material’s resistance to high temperatures and sterilization methods ensures safe reuse. The tubing’s durability reduces the need for frequent replacements, providing long-term cost efficiency. The non-toxic nature of the tubing minimizes the risk of adverse reactions in patients.

Common uses in food processing

Food processing facilities use thin wall silicone tubing for various applications. The tubing transfers liquids, such as juices and sauces, without contamination. The flexibility of the tubing simplifies installation and maintenance, reducing downtime. The tubing’s chemical resistance ensures longevity, even in harsh processing environments.

Uses in industrial applications

Thin wall silicone tubing exhibits excellent chemical resistance, making it suitable for industrial applications. The tubing withstands exposure to acids, bases, and solvents, ensuring durability in demanding environments. This property enhances the longevity of equipment and machinery, reducing maintenance costs.

Uses in manufacturing processes

Manufacturing industries rely on thin wall silicone tubing for various processes. The tubing serves as conduits for fluids, gases, and electrical wiring. The material’s insulating properties protect against electrical hazards. The tubing’s flexibility allows for easy integration into complex designs and tight spaces.

What factors need to be considered when selecting thin wall silicone tubing

Specific needs based on industry

Different industries have unique requirements for thin wall silicone tubing. The medical field demands biocompatibility and sterilizability. Food and beverage sectors require compliance with food-grade standards. Industrial applications need chemical resistance and durability. Understanding these specific needs ensures the selection of suitable tubing.

Matching tubing properties to applications

Matching the properties of thin wall silicone tubing to its intended application is crucial. High-temperature environments benefit from tubing with excellent temperature resistance. Applications involving movement or vibration require flexible and elastic tubing. Chemical processing industries need tubing with superior chemical resistance. Proper matching enhances performance and longevity.

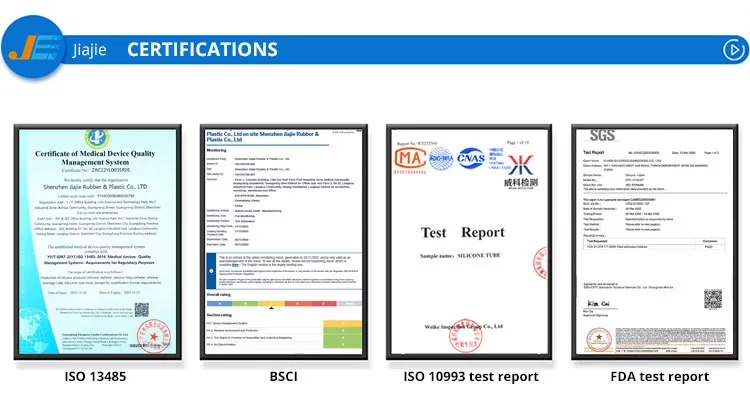

Industry standards and certifications

Adhering to industry standards and certifications guarantees the quality of thin wall silicone tubing. Medical-grade tubing must meet FDA and ISO 10993 standards. Food-grade tubing should comply with FDA and NSF regulations. Industrial tubing often requires compliance with ASTM standards. These certifications ensure safety and reliability.

Ensuring product quality

Ensuring the quality of thin wall silicone tubing involves several steps. Manufacturers should conduct rigorous testing for flexibility, durability, and chemical resistance. Quality control processes should include inspections for defects and consistency. Using high-quality raw materials enhances the overall performance of the tubing. Reliable manufacturers provide documentation of compliance with industry standards.