JESilicone provides one-stop custom silicone products service for a broad range of industries including medical, food & beverage, electronics, automotive and more. Our custom silicone product range includes extrusions, moldings, sheeting, gaskets and seals. From simple seals to the most complex silicone parts, we utilize many sophisticated technologies and processes to consistently manufacture high-quality silicone products to meet your application's demand. The following are part of our successful cases of custom silicone products.

Custom Silicone Sleeves / Silicone Covers / Silicone Parts

Custom Silicone Gaskets and O-rings

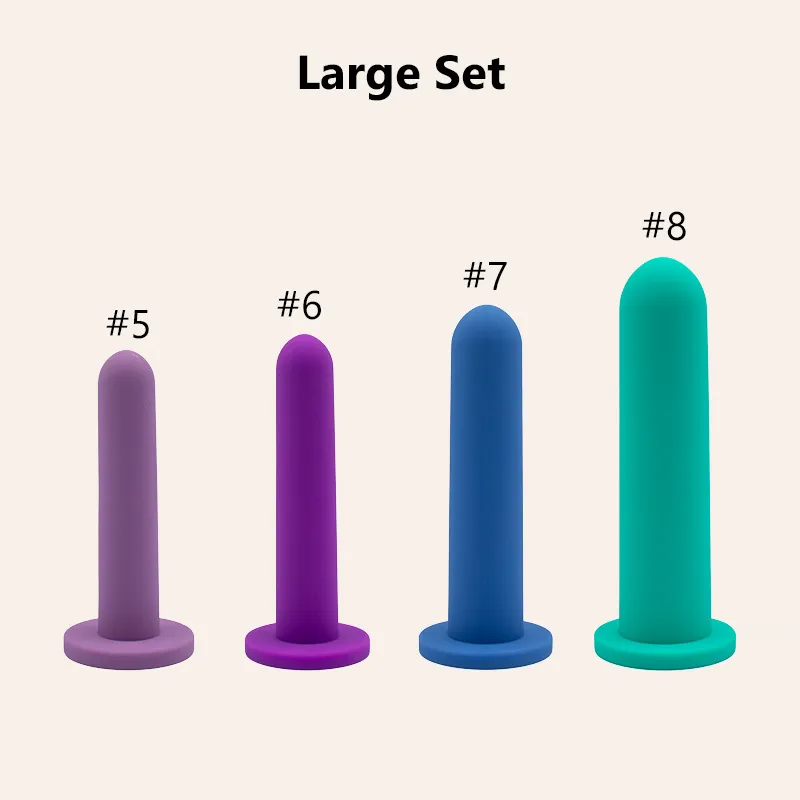

Custom Silicone Molded Parts

Custom Liquid Silicone Products

Guide to Custom Silicone Products Manufacturing

Conceptualization and Design for Customized Silicone Products

Identifying Product Requirements

Understanding product requirements is the first step in designing custom silicone products. Identify specific needs for functionality, durability, and aesthetics. Consider the environment where the product will be used. Evaluate factors such as temperature, chemical exposure, and mechanical stress. This evaluation ensures that custom silicone products meet all necessary specifications.

Creating Design Prototypes

Creating prototypes allows for testing and refinement. Use 3D modeling to visualize designs. Develop physical prototypes using techniques like 3D printed tooling. Prototyping helps in assessing the design's feasibility. Make necessary adjustments before moving to full-scale production. This process ensures that custom silicone products achieve desired outcomes.

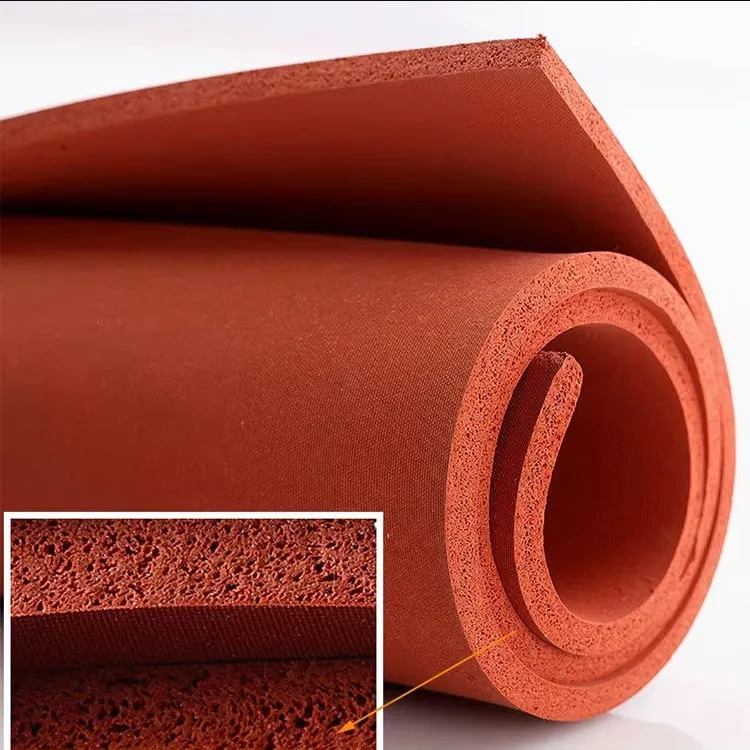

Material Selection for Customized Silicone Products

Choosing the Right Silicone Type

Selecting the appropriate silicone type is crucial. Consider the properties required for the product. Liquid Silicone Rubber (LSR) suits intricate designs. High Consistency Rubber (HCR) offers robust mechanical properties. Room Temperature Vulcanizing (RTV) silicone provides quick setting. Each type serves different needs for custom silicone products.

Considering Additives and Fillers

Additives and fillers enhance silicone properties. Use additives to improve flexibility or color. Fillers can increase strength or reduce cost. Choose based on the specific application of the product. Proper selection ensures that custom silicone products perform optimally. This step tailors the material to meet unique client demands.

Custom Silicone Products Molding Techniques Includes Compression Molding, Injection Molding and Transfer Molding

Compression Molding

Compression molding involves placing silicone material into a heated mold. The mold closes, applying pressure to shape the material. This technique suits large parts and simple designs. Industries choose compression molding for its cost-effectiveness in low-quantity production. The equipment costs less compared to other methods.

Injection Molding

Injection molding injects liquid silicone into a mold cavity. This process works well for complex and smaller parts. High quantities of small- or medium-sized items benefit from injection molding's efficiency. Manufacturers prefer this method for its precision and speed. The process allows for intricate designs and consistent quality.

Transfer Molding

Transfer molding combines features of both compression and injection molding. Silicone material transfers into a mold through a plunger. This technique excels in producing high-precision parts. Industries use transfer molding for exact quantities and lower per-unit costs. The method provides excellent control over the final product's dimensions.

Quality Control and Testing

Ensuring Product Consistency

Quality control ensures that each silicone product meets specifications. Consistent product quality requires regular monitoring during production. Manufacturers implement strict guidelines to maintain uniformity. Each batch undergoes inspection to verify adherence to standards. Consistency builds trust with clients and enhances product reliability.

Testing for Durability and Safety

Testing evaluates the durability and safety of silicone products. Products undergo stress tests to measure resistance to wear and tear. Safety assessments check for potential hazards in use. Manufacturers conduct chemical stability tests to ensure safety in various environments. Rigorous testing guarantees that products perform as expected under different conditions.

How to Select the Best Custom Silicone Products Manufacturer

Selecting the best custom silicone product manufacturer involves several key considerations. Here’s a step-by-step guide to help you make an informed decision:

- Identify Your Needs

Product Specifications: Define the type of silicone product you need, including dimensions, design, and intended use.

Volume Requirements: Determine the quantity you’ll need for initial orders and ongoing production.

- Research Manufacturers

Experience and Expertise: Look for manufacturers with a solid track record in producing silicone products. Check how long they’ve been in business and their specific areas of expertise.

Industry Reputation: Read reviews, testimonials, and case studies. Networking in industry forums can provide insights.

- Assess Capabilities

Technology and Equipment: Ensure the manufacturer has modern machinery and technology suitable for your product specifications.

Customization Options: Verify their ability to create custom molds and designs to meet your requirements.

- Quality Control

Certifications: Check for relevant quality certifications (e.g., ISO, FDA compliance) that ensure product safety and quality.

Testing Procedures: Inquire about their quality control processes and whether they conduct regular testing.

- Production Processes

Lead Times: Understand their production timeline from design to delivery.

Flexibility: Assess how adaptable they are to changes in design or order volume.

- Communication and Support

Responsiveness: Evaluate how quickly and effectively they communicate. Good communication is crucial for successful collaboration.

Customer Support: Look for a manufacturer that provides ongoing support throughout the project lifecycle.

- Sample Production

Prototyping: Request samples or prototypes to evaluate quality and fit before committing to a larger order.

Feedback Loop: Ensure they are open to feedback during the prototyping phase.

- Logistics and Shipping

Location: Consider the manufacturer’s location for shipping costs and times.

Shipping Options: Ask about their logistics capabilities and how they handle shipping and delivery.

- Long-term Partnership

Scalability: Ensure they can handle future growth in production as your needs evolve.

Relationship: Look for a manufacturer that values building a long-term partnership rather than just a one-off transaction.