What are Silicone Foam Tubes?

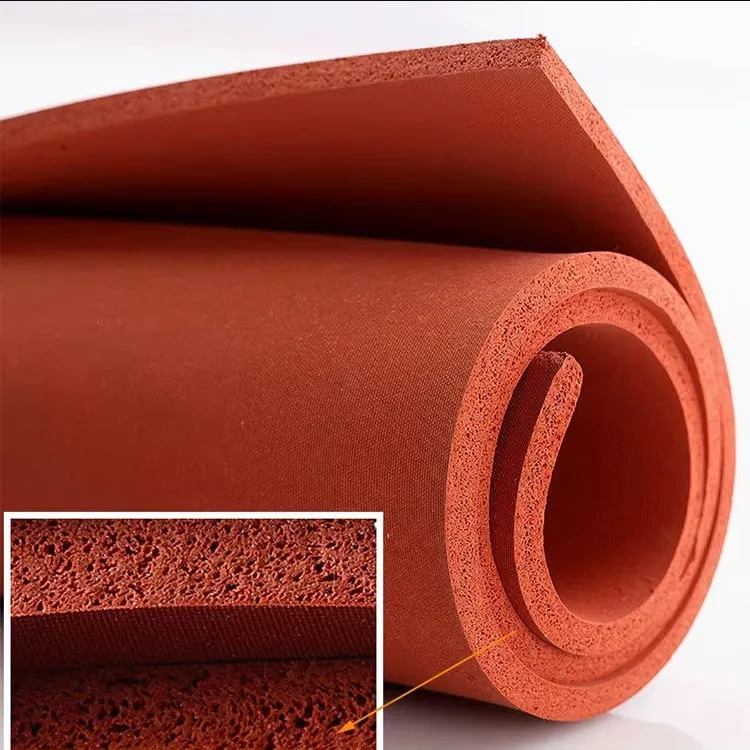

A silicone foam tube is a type of tubing crafted from silicone foam material. This material exhibits lightweight, compressible, and flexible characteristics. Excellent thermal and electrical insulation properties define silicone foam. Resistance to water, chemicals, and UV radiation further enhances its suitability for diverse applications. The closed-cell structure of the silicone foam tube ensures that tiny bubbles formed during heat curing do not connect, providing superior sealing and insulating capabilities.

Manufacturing Process of Silicone Sponge Tubing

The manufacturing process of a silicone sponge tubing involves several key steps. Initially, raw silicone material undergoes mixing with blowing agents. This mixture then enters an extrusion machine where it shapes into tubes. The extruded tubes proceed to a heat-curing stage. During this phase, the material expands, creating the closed-cell structure. The final product undergoes quality checks to ensure compliance with industry standards.

Key Properties of Silicone Foam Sponge Tubes

Physical Properties: Silicone foam tubes exhibit lightweight, high flexibility, and compressibility. The closed-cell structure provides excellent cushioning and shock absorption.

Chemical Properties: Silicone sponge tubes can resist a wide range of chemicals, such as oils, solvents, and other harsh substances. This resistance ensures durability and longevity in demanding environments.

Thermal Properties: Silicone foam tubes provide effective thermal insulation, maintaining stability across a broad temperature range. Resistance to extreme temperatures makes them suitable for both high-heat and low-temperature applications.

Why Use Silicone Foam Tubing?

Comparison with Traditional Rubber and Plastic Materials: When compared to traditional rubber and plastic materials, silicone foam tubes offer several advantages, including better heat resistance, flexibility, and longevity. Traditional materials may degrade more quickly when exposed to high temperatures or harsh chemicals, whereas silicone foam tubes maintain their properties for a longer period. Additionally, silicone foam tubes are more lightweight, which can reduce transportation costs and improve the overall performance of systems.

Cost Efficiency in the Long Run: Silicone foam tubes's durability and long lifespan make them more cost-effective over time. Businesses that choose silicone foam tubes can expect fewer maintenance and replacement costs, as well as reduced downtime in critical systems.

Silicone Foam Tube: Open-Cell vs. Closed-Cell

Open-cell silicone foam tubes feature interconnected cells. These cells allow the absorption and release of liquids or gases. This structure provides superior cushioning and flexibility. Open-cell tubes excel in applications requiring breathability and moisture management. The lightweight nature of open-cell foam enhances its usability in various industries.

Closed-cell silicone foam tubes possess a denser and less porous structure. This design makes them impermeable to air or water. Closed-cell tubes offer rigidity and stability. These tubes provide excellent sealing and insulation properties. The closed-cell structure ensures minimal fluid absorption, making them ideal for demanding environments.

Applications of Silicone Foam / Sponge Tubing

JESilicone can provide almost any silicone foam tube solution you require, and manufacture the highest quality foam tubes.Our sponge silicone tubing is used in many applications, such as insulation and sealing processes, the following are some common uses:

1. Pipe insulation, and protect pipes in residential, commercial, and industrial settings.

2. Used in HVAC systems to insulate refrigerant lines and ductwork。

3. Used to insulate and protect electrical wiring and cables.

4. Provide some sound-dampening properties, which is useful in applications where noise reduction is necessary.

5. Used to insulate and protect various components in vehicles.

6. Used in various sports and recreation equipment.

7. Used for grips for utensils.

Read more about: Complete Guide to Silicone Foam Tubes: Benefits, Applications, Customization & Market Trends

As a more than 20 years silicone product supplier, JEsilicone manufactures a wide range of standard and customized silicone foam tubes. Our silicone foam tubes offer versatile solutions for insulation, protection, and cushioning. Various specifications can be customized according to the requirements by different customers.

Any Requirement About Silicone Foam Tubing? Our engineers are here to help you.

Please feel free to leave your message. Our experienced engineers will reply to you as soon as possible.