Medical Silicone Tubing: Definition and Uses

Medical silicone tube plays a vital role in modern healthcare. This tubing offers exceptional biocompatibility, flexibility, and durability. Medical professionals rely on medical silicone tubes for critical applications such as drug delivery systems, catheters, and respiratory devices. The market for medical silicone tubing is growing rapidly, with a projected CAGR of 6% due to its increasing demand. Its unique properties make medical silicone tubing indispensable in the medical field.

What is Medical Silicone Tubing?

Definition

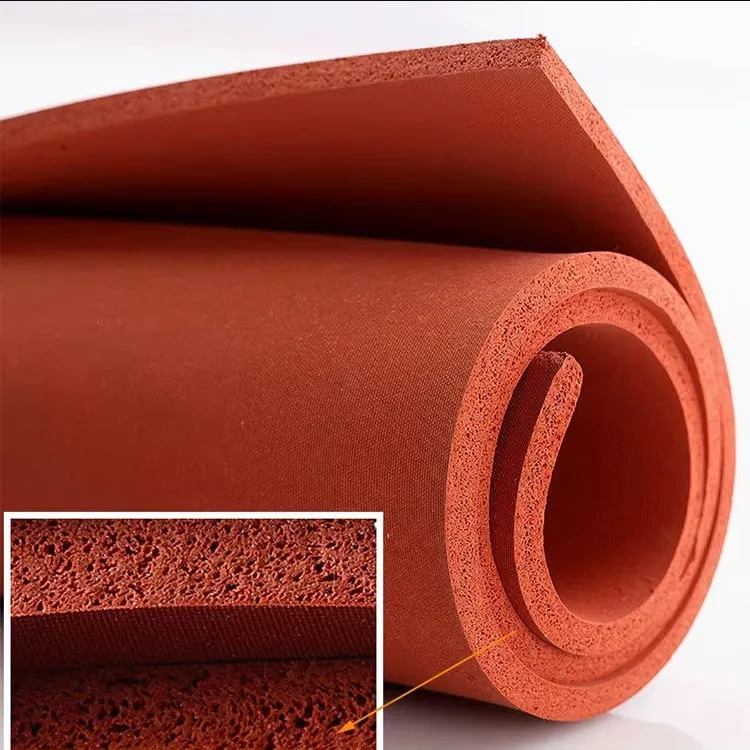

Medical silicone tubing serves as a flexible, hollow conduit made from silicone polymer. This synthetic material stands out for its exceptional biocompatibility and inertness. Unlike traditional materials such as rubber or plastic, silicone tubing offers a unique combination of properties ideal for medical applications.

Basic characteristics

Medical silicone tubing exhibits remarkable flexibility, durability, and resistance to a wide range of environmental factors. These characteristics make the tubing an indispensable component in various medical devices. The tubing can withstand extreme temperatures, resist chemical reactions, and maintain structural integrity over long periods. This makes medical silicone tube suitable for critical applications in healthcare.

Comparison with other materials

When compared to other materials like rubber or plastic, medical silicone tubing offers superior biocompatibility and physical properties. Rubber may cause allergic reactions and degrade over time. Plastic lacks the flexibility and durability required for many medical applications. Medical silicone tube, on the other hand, resists adhesion, supports no bacterial growth, and maintains high elasticity without the need for plasticizers. These advantages make medical silicone tubing the preferred choice in the medical industry.

Medical Silicone Tube Manufacturing Process

The manufacturing process of medical silicone tubing involves several steps to ensure high quality and performance.

Raw materials used

The production of medical silicone tubing begins with high-purity silicone polymers. These polymers must meet stringent medical-grade standards to ensure safety and effectiveness. Different grades of silicone, such as FDA Grade, Class VI Grade, and Platinum Cure Grade, provide various options for specific applications. Platinum Cure Grade tubing, for instance, is extremely robust and widely used in healthcare and pharmaceutical sectors.

Production techniques

Manufacturers employ advanced production techniques to create medical silicone tubing. These techniques include extrusion, molding, and curing processes. Extrusion involves forcing silicone through a die to form a continuous tube. Molding shapes the silicone into specific forms using molds. Curing solidifies the silicone, enhancing its strength and durability. Innovations in manufacturing, such as 3D printing and automation, further improve efficiency and customization, attracting various end-users.

Benefits of Medical Silicone Tubing

Importance in medical applications

Medical silicone tube exhibits exceptional biocompatibility, making it ideal for healthcare applications. Biocompatibility ensures that the tubing does not cause adverse reactions when in contact with human tissues or fluids. This property is crucial for devices like catheters and drug delivery systems. The inert nature of the medical silicone tube prevents any chemical interaction with medications or bodily fluids. This feature enhances patient safety and treatment efficacy.

Examples of biocompatible uses

Medical silicone tube finds extensive use in various biocompatible applications. Catheters made from silicone tubing minimize the risk of infections and allergic reactions. Drug delivery systems utilize silicone tubing to ensure precise and safe administration of medications. Respiratory devices also benefit from the biocompatibility of silicone tubing, providing a safe conduit for gases and vapors. These examples highlight the critical role of medical silicone tube in enhancing patient care and medical outcomes.

Long-term use

The durability of medical silicone tube makes it suitable for long-term use in healthcare settings. Silicone tubing withstands repeated sterilization processes without degrading. This longevity reduces the need for frequent replacements, lowering costs and minimizing waste. The robust nature of medical silicone tube ensures consistent performance over extended periods. This reliability is essential for devices that require continuous operation, such as infusion pumps and drainage systems.

Adaptability in various conditions

Medical silicone tube offers remarkable flexibility, allowing it to adapt to various conditions. The tubing maintains its structural integrity under extreme temperatures and pressures. This adaptability makes medical silicone tube suitable for diverse medical applications. For instance, silicone tubing can function effectively in both high-temperature sterilization and low-temperature storage environments. The flexibility of the tubing also enables easy manipulation during surgical procedures, enhancing precision and control.

Applications of Medical Silicone Tubes

Surgical Applications

Types of surgeries

Medical silicone tubing plays a crucial role in various surgical procedures. Surgeons use this tubing in cardiovascular surgeries to facilitate blood flow and ensure patient safety. Orthopedic surgeries also benefit from the flexibility and durability of silicone tubing. Neurosurgeons employ silicone tubing for shunt systems to manage cerebrospinal fluid. The versatility of medical silicone tubing makes it indispensable in diverse surgical fields.

Specific examples

In cardiovascular surgeries, medical silicone tubing assists in bypass procedures and heart valve replacements. Orthopedic surgeons use silicone tubing for irrigation during joint replacements. Neurosurgeons rely on silicone tubing for ventricular shunts to treat hydrocephalus. Each application highlights the tubing's adaptability and reliability in critical surgical settings.

Pharmaceutical and Laboratory Uses

Drug delivery systems

Pharmaceutical companies utilize medical silicone tubing in drug delivery systems. The tubing ensures precise and controlled administration of medications. Infusion pumps and insulin delivery devices depend on silicone tubing for consistent performance. The biocompatibility of silicone tubing prevents adverse reactions, ensuring patient safety.

Laboratory equipment

Laboratories employ medical silicone tubing in various equipment. Peristaltic pumps use silicone tubing for fluid transfer and sample handling. Chromatography systems rely on silicone tubing for accurate separation processes. The chemical resistance of silicone tubing makes it ideal for handling aggressive solvents and reagents. These applications demonstrate the tubing's importance in maintaining the integrity of laboratory procedures.

Other Medical Uses

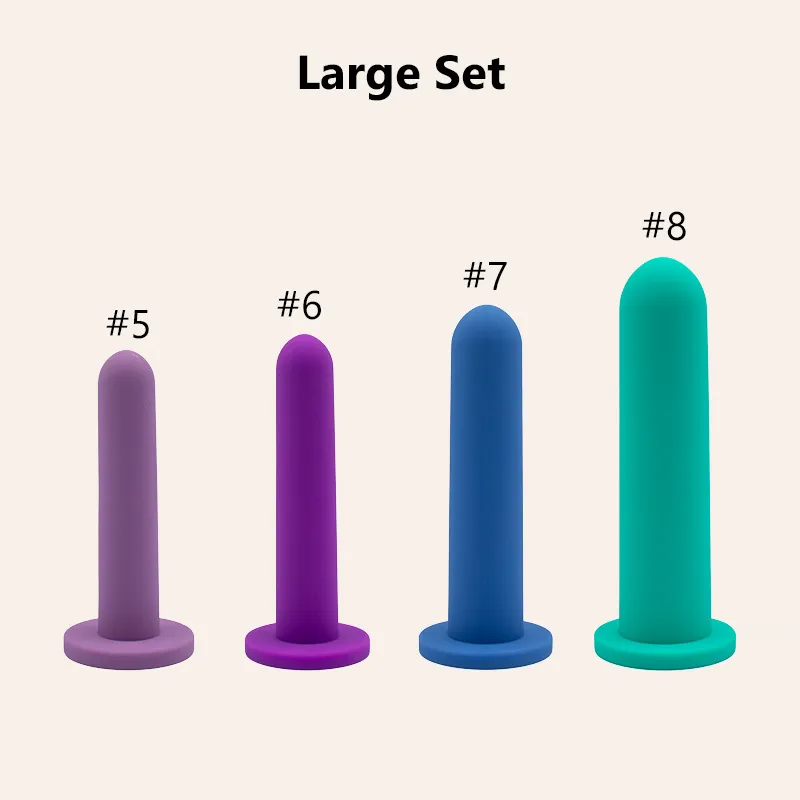

Catheters

Medical silicone tubing is essential in the production of catheters. The biocompatibility of silicone tubing reduces the risk of infections and allergic reactions. Urinary catheters, central venous catheters, and dialysis catheters all benefit from the properties of silicone tubing. The tubing's flexibility allows for easy insertion and patient comfort.

Respiratory devices

Respiratory devices also rely on medical silicone tubing. Ventilators use silicone tubing to deliver oxygen and remove carbon dioxide. Continuous Positive Airway Pressure (CPAP) machines for sleep apnea patients incorporate silicone tubing for airflow management. The durability and flexibility of silicone tubing ensure reliable performance in respiratory care.

Medical silicone tubing's unique properties make it a preferred choice in various medical applications. Its biocompatibility, flexibility, and durability enhance the performance and safety of medical devices across multiple fields.