Peristaltic Pumps Silicone Tubing: A Comprehensive Guide

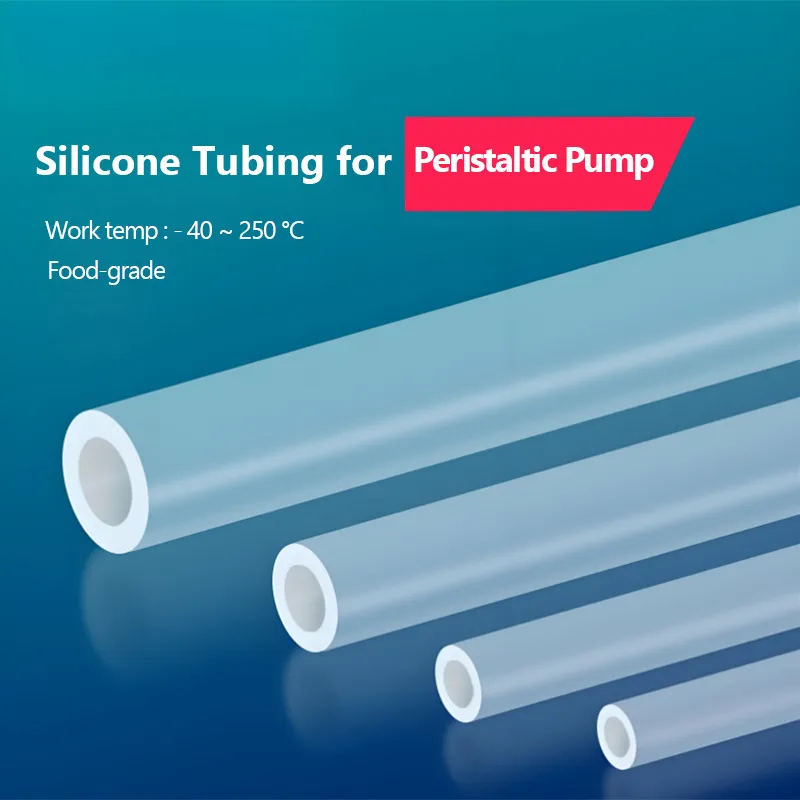

Peristaltic pump silicone tubing is designed for precise fluid transfer in various applications, including medical, laboratory, and industrial settings. Made from high-quality silicone, it offers excellent flexibility, durability, and resistance to abrasion, ensuring reliable performance over time. The tubing is non-toxic, biocompatible, and resistant to a wide range of chemicals, making it ideal for applications requiring high hygiene standards. Its smooth inner surface minimizes the risk of contamination and ensures consistent flow. Available in various sizes and lengths, peristaltic pump silicone tubing is a key component for applications requiring accurate and efficient fluid handling.

JESilicone is a leading manufacturer of peristaltic pump silicone tubing, boasting over 20 years of expertise.

Click here for more details on our silicone tubing for peristaltic pumps.

What Is Peristaltic Pump Silicone Tubing?

Definition and Function of Peristaltic Pumps

Definition of Peristaltic Pumps:

A peristaltic pump, also known as a hose pump or a roller pump, is a type of positive displacement pump that moves fluids through flexible tubing. It operates based on the principle of peristalsis, a process similar to the natural muscle contractions seen in the human digestive system. As rollers or shoes press against the tubing, they create a moving "pocket" of fluid that is pushed along the tube. This action is repeated in a continuous cycle, ensuring a steady flow of the fluid.

Function of Peristaltic Pumps:

- Peristaltic pumps are designed to transport a wide variety of liquids, including chemicals, foodstuffs, and biological fluids, in a controlled and precise manner. Key functions include:

- Precise Flow Control: These pumps allow for accurate and consistent flow rates, making them ideal for applications that require precise fluid dispensing, such as in laboratories or pharmaceutical production.

- Gentle Fluid Handling: Since the fluid never comes into direct contact with the pump’s mechanical parts, it’s less prone to damage or contamination. This is especially beneficial when handling sensitive fluids like cell cultures or medical fluids.

- Self-Priming: Peristaltic pumps can operate without the need for external priming, allowing them to start moving fluids from dry or empty conditions easily.

- Durability and Versatility: These pumps are highly resistant to clogging and wear, as the fluid path is always sealed by the tubing. They are also capable of pumping a wide range of viscosities and are suitable for both low and high-pressure applications.

- Easy Maintenance: Since the fluid only contacts the tubing, maintenance is simple—only the tubing needs to be replaced periodically. This makes peristaltic pumps easy to maintain and cost-effective in the long term.

Types of Peristaltic Pump Tubing

Peristaltic pump tubing comes in a variety of materials, each suited to different applications based on factors like chemical resistance, flexibility, and temperature tolerance. Peristaltic pump silicone tubing is one of the most popular options due to its excellent flexibility, high-temperature resistance, and biocompatibility. It is ideal for medical, food, and pharmaceutical industries where hygiene and non-toxicity are essential. Silicone’s smooth interior prevents clogging, and its ability to withstand extreme temperatures makes it a top choice for sterile environments, ensuring both reliable and consistent performance in critical applications.

Peristaltic pump tubing is also divided into various types based on different materials, such as PVC tubing, Tygon Tubing, Santoprene Tubing, Norprene Tubing, Viton Tubing, Polyurethane (PU) Tubing, EPDM Tubing, etc.

Key Benefits of Using Silicone Tubing in Peristaltic Pumps

Superior Chemical Resistance

The superior chemical resistance of silicone tubing, especially when used in peristaltic pumps, makes it an ideal material for handling a wide variety of aggressive chemicals. Silicone rubber’s molecular structure provides excellent stability and resistance to both organic and inorganic substances, preventing degradation or chemical reaction even when exposed to harsh environments. This resistance allows peristaltic pumps equipped with silicone tubing to transfer corrosive liquids, solvents, and acids without the risk of tubing failure or contamination. Additionally, silicone maintains its flexibility and strength over time, even when subjected to fluctuating temperatures, ensuring consistent performance in critical applications across industries such as pharmaceuticals, biotechnology, and food processing. This makes silicone tubing an indispensable choice for demanding fluid handling systems.

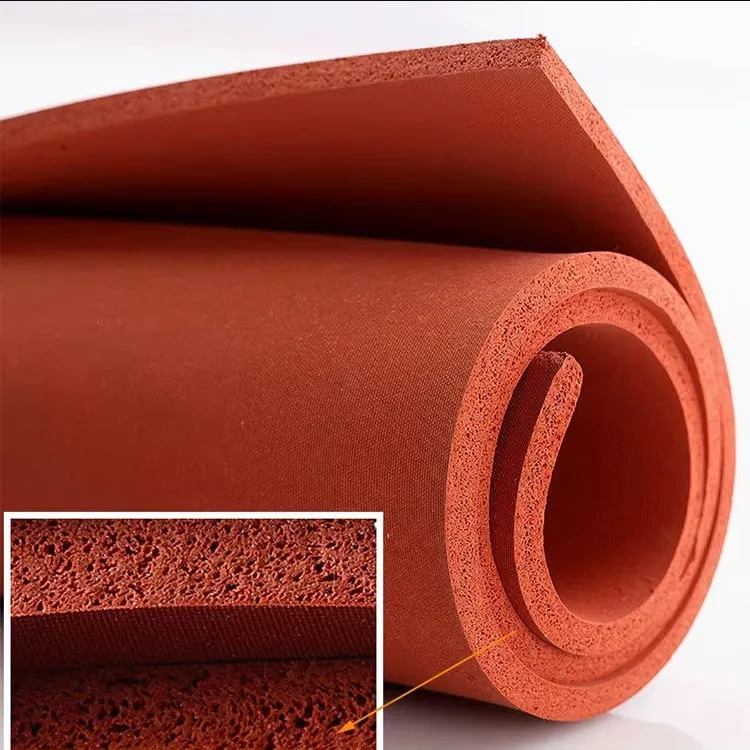

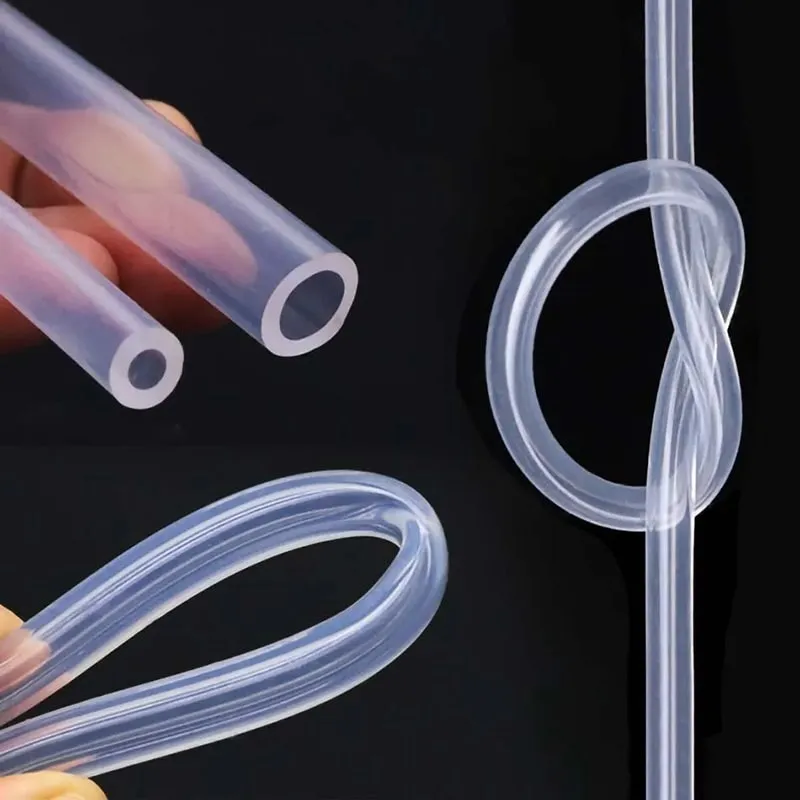

Flexibility and Durability

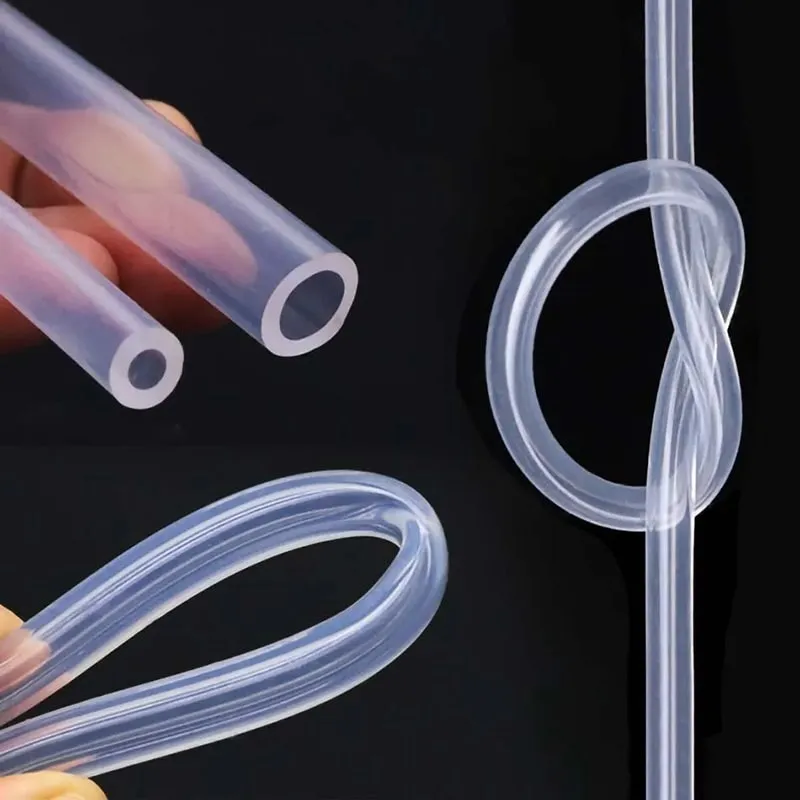

Silicone tubing used in peristaltic pumps is renowned for its exceptional flexibility and durability, which are crucial for reliable and long-lasting performance. The inherent flexibility of silicone allows the tubing to bend and stretch easily without cracking or kinking, ensuring smooth fluid transfer even in tight or complex piping systems. This flexibility also enables the tubing to withstand repetitive compression and elongation from the peristaltic pump rollers, which helps in maintaining a consistent flow rate over time. Additionally, silicone's durability means that it resists wear and tear, even under continuous operation or exposure to mechanical stress. Unlike many other materials, silicone tubing remains flexible and maintains its structural integrity throughout its lifespan, even in challenging environments. This combination of flexibility and durability makes silicone tubing an ideal choice for demanding applications in industries such as pharmaceuticals, food and beverage, and chemical processing, where performance, reliability, and long-term operation are essential.

Key Industries for Peristaltic Pumps Silicone Hoses

Peristaltic pumps silicone hoses are widely used across industries that require precise, contamination-free fluid handling. Key sectors include pharmaceuticals and biotech, where sanitary conditions are vital for handling drugs and cultures. In food and beverage, they ensure hygienic transport of ingredients. Water treatment facilities rely on these pumps for chemical dosing and filtration. The cosmetic and chemical industries also benefit from their ability to transfer delicate or aggressive substances safely. Other applications include laboratories, medical devices, and printing industries, all demanding accurate and sterile fluid management.

Healthcare and Pharmaceutical Applications

Peristaltic pumps with silicone hoses are crucial in healthcare and pharmaceutical applications due to their ability to provide accurate, contamination-free fluid handling.

In the pharmaceutical industry, these pumps are used for the precise dosing of active ingredients, vaccines, and other sensitive liquids. The silicone hoses prevent contamination, making them ideal for sterile environments.

In healthcare, they are commonly employed in drug delivery systems, including IV pumps and dialysis machines, where precise flow rates are critical for patient safety. The gentle, non-invasive pumping action of peristaltic pumps ensures that delicate biological fluids like blood, nutrients, or hormones are transported without degradation. Moreover, silicone's biocompatibility and resistance to temperature and chemicals make it a preferred material for these pumps in applications such as fluid management in clinical diagnostics and laboratory automation.

Overall, the combination of accuracy, reliability, and hygienic performance makes peristaltic pumps with silicone hoses indispensable in healthcare and pharmaceutical settings.

Food and Beverage Industry

Peristaltic pumps with silicone hoses play a vital role in the food and beverage industry due to their hygienic and precise fluid handling capabilities. These pumps are used for transferring liquids such as juices, sauces, dairy products, and liquid sweeteners without contamination, ensuring the highest quality standards. Silicone hoses are particularly valued for their resistance to temperature extremes, which is essential during pasteurization or sterilization processes. The non-contact nature of peristaltic pumps ensures that the product only comes into contact with the hose, reducing the risk of contamination or product degradation. Additionally, their ability to handle varying viscosities makes them suitable for both thin liquids and thicker substances like puree or batter. These pumps also ensure accurate dosing of ingredients in recipe formulations, improving consistency and efficiency in production lines.

Overall, the combination of silicone's flexibility, durability, and non-contaminating properties makes peristaltic pumps an essential tool in food and beverage manufacturing.

How to Choose the Right Silicone Tubing for Your Peristaltic Pump

When selecting silicone tubing for your peristaltic pump, several key factors should be considered to ensure optimal performance. First, focus on the tubing's size. The inner diameter must match the pump’s specifications to maintain accurate flow rates. Next, consider the tubing's hardness or Shore A hardness. Softer tubing provides better compression and flexibility, ideal for delicate fluids, while harder tubing may offer greater durability and resistance to wear. Chemical compatibility is crucial—ensure the silicone material is resistant to the fluids being pumped, particularly if they are aggressive or have high temperatures. Additionally, look at the tubing’s pressure and temperature tolerance, as peristaltic pumps can generate high pressure and may operate in varying thermal conditions. Lastly, opt for bio-compatibility if using the pump in medical or food applications to prevent contamination. Properly chosen silicone tubing enhances pump efficiency, reduces maintenance, and ensures the longevity of both the tubing and pump.

Sizing and Compatibility with Pumps

When choosing silicone tubing for a peristaltic pump, proper sizing is critical to ensuring optimal performance and efficiency. The inner diameter (ID) of the tubing directly impacts the flow rate, as it determines the volume of fluid that can be moved per revolution. It's essential to match the tubing’s ID with the pump’s specifications for accurate fluid delivery. If the tubing is too narrow, it may cause excessive pressure and wear on both the tubing and pump components. Conversely, too wide a diameter can result in reduced flow accuracy and efficiency.

In addition to sizing, compatibility with the pump must be considered. Different pumps may require specific tubing types due to varying roller configurations and tube compressions. Tubing that is too rigid or too soft may not work well with certain pump designs, affecting performance. Always ensure the selected silicone tubing fits the pump’s roller and head size, and is designed for smooth, consistent operation across the pump's speed range.

Temperature Resistance and Chemical Compatibility

When selecting silicone tubing for a peristaltic pump, temperature resistance and chemical compatibility are two crucial factors to consider. Silicone tubing is known for its excellent temperature stability, but each type has specific limits. Ensure the tubing you choose can withstand the operating temperature range of both the pump and the fluid being pumped. Tubing with inadequate temperature resistance may become brittle or lose flexibility, leading to failure or inconsistent flow. Always check the manufacturer's specifications for maximum and minimum temperature tolerances.

Chemical compatibility is equally important, especially if the pump is handling aggressive or corrosive fluids. Silicone is generally resistant to a wide range of chemicals, but it’s essential to verify that the specific type of silicone tubing is compatible with the chemicals in use. Incompatible materials may cause the tubing to degrade, leading to leaks, contamination, or a compromised pump performance. Consider factors like pH, solvent type, and fluid concentration when selecting the right tubing to avoid costly downtime or maintenance.

FAQs about Peristaltic Pumps Silicone Tubing

1. What is silicone tubing used for in peristaltic pumps?

Silicone tubing is used in peristaltic pumps because of its flexibility, durability, and resistance to wear and tear. It ensures a smooth, consistent flow while preventing contamination by maintaining a sealed environment. This makes it ideal for medical, pharmaceutical, and food processing applications where hygiene is critical.

2. What makes silicone tubing ideal for peristaltic pumps?

Silicone tubing is ideal due to its high flexibility and ability to return to its original shape after being compressed. It’s resistant to heat, UV light, and chemicals, making it a versatile choice for various applications. Additionally, its non-reactive nature prevents contamination of the pumped fluids, ensuring purity and safety.

3. How does silicone tubing perform under different temperatures?

Silicone tubing performs exceptionally well across a wide range of temperatures, from -50°C to 250°C. It maintains its flexibility and elasticity even in extreme heat or cold. This thermal resilience ensures that peristaltic pumps can function effectively in a variety of industrial and laboratory conditions.

4. Can silicone tubing be used for all types of fluids in peristaltic pumps?

Silicone tubing is compatible with many types of fluids, including water, oils, food-grade liquids, and some chemicals. However, it may not be suitable for all aggressive chemicals or solvents. It's important to check compatibility with specific fluids to ensure optimal performance and avoid degradation.

5. How long does silicone tubing last in peristaltic pumps?

The lifespan of silicone tubing in peristaltic pumps depends on factors such as the fluid type, operating pressure, and frequency of use. Typically, high-quality silicone tubing can last for months to years. Regular maintenance, such as cleaning and inspecting for wear, can extend its life and maintain efficient pump performance.

6. What are the benefits of using silicone tubing in peristaltic pumps over other materials?

Silicone tubing offers several benefits over other materials, including superior flexibility, a wide temperature range, and resistance to many chemicals. It is also non-toxic, making it safe for use in sensitive applications like food and medical fields. Additionally, silicone tubing is easy to sterilize, ensuring hygiene is maintained during operation.

7. How do I choose the right silicone tubing for my peristaltic pump?

Choosing the right silicone tubing involves considering factors such as the pump's flow rate, the type of fluid being pumped, and the operating environment. Key factors include tubing size, wall thickness, temperature tolerance, and chemical compatibility. Consult the pump manufacturer’s guidelines for recommended specifications.

8. Is silicone tubing flexible enough to fit all peristaltic pump models?

Silicone tubing is highly flexible and can fit a wide range of peristaltic pump models. However, it is important to select the right inner and outer diameter to ensure a secure fit and optimal performance. Many pumps come with size options to accommodate different tubing dimensions. Always verify compatibility with your specific pump.

9. Can silicone tubing be reused in peristaltic pumps?

Silicone tubing can be reused as long as it remains in good condition and shows no signs of wear, cracking, or degradation. Proper cleaning and sterilization after each use help prolong its life. However, over time, repeated use and compression may lead to reduced elasticity and flow consistency.

10. What maintenance is required for silicone tubing in peristaltic pumps?

Regular maintenance of silicone tubing includes inspecting for wear, cracks, or discoloration. It should be cleaned after each use with appropriate solutions to prevent bacterial buildup. Ensuring the tubing is free of contaminants and checking for proper alignment will help maintain the pump’s efficiency and extend the tubing's lifespan.

Peristaltic pump silicone tubing plays a crucial role in ensuring the reliable and efficient transfer of fluids in various industries. Known for its excellent chemical resistance, flexibility, and temperature tolerance, silicone tubing is ideal for applications requiring precise fluid handling, such as in healthcare, pharmaceuticals, food, and beverage industries. Its inert properties make it safe for transporting sensitive fluids, and its durability ensures long-lasting performance under demanding conditions.

Choosing the right silicone tubing for a peristaltic pump involves considering factors such as tubing size, wall thickness, temperature resistance, and compatibility with specific pump models. Proper maintenance, including regular inspections for signs of wear, kinks, or blockages, is essential to ensure optimal pump performance and prevent disruptions in fluid flow. Additionally, silicone tubing’s smooth interior helps reduce bacterial build-up, making it particularly suitable for food-grade and medical applications.

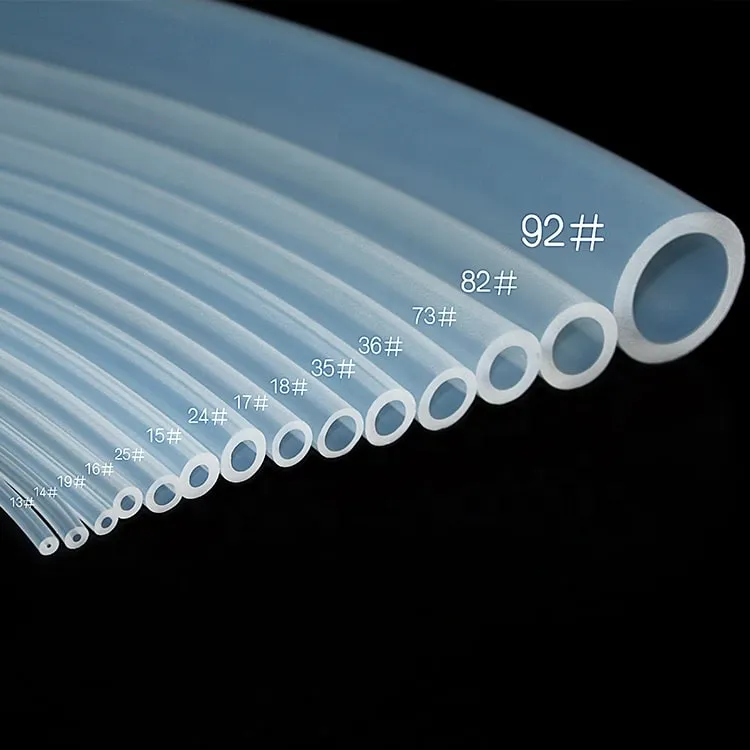

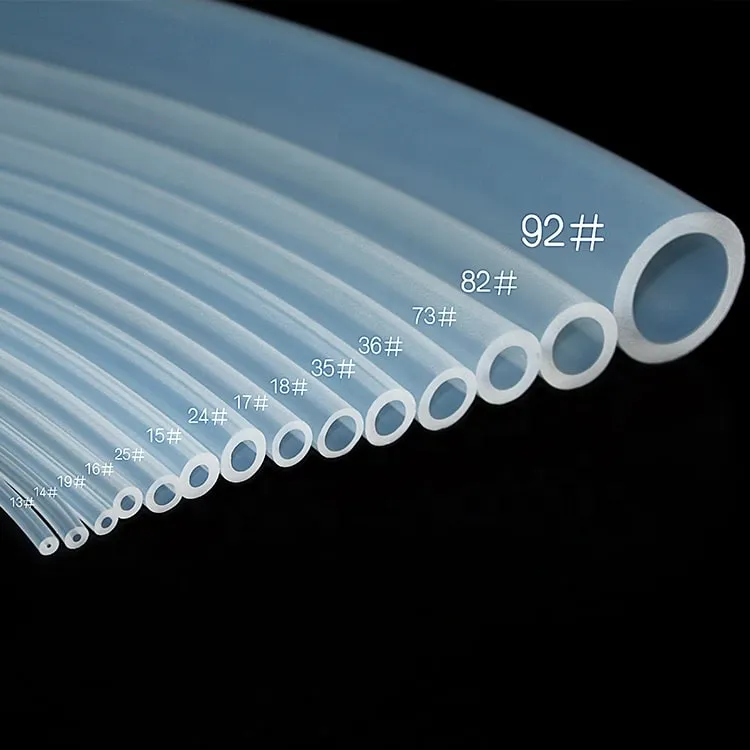

JESilicone offers professional customization and production of high-quality peristaltic pump silicone tubing in a wide range of sizes (such as 13# 14# 15# 16# 17# 18# 24# 25# 35# 36# 73# 82# 86# 88# 90# 92#,etc). With over 20 years of expertise and advanced manufacturing techniques, we ensure that each tube meets the highest standards of durability and performance. Whether you need specific dimensions or unique requirements, we are committed to providing tailored solutions to suit your needs. Contact us now for more details and a competitive quote. We look forward to assisting you with your project!

In Conclusion

Peristaltic pump silicone tubing plays a crucial role in ensuring the reliable and efficient transfer of fluids in various industries. Known for its excellent chemical resistance, flexibility, and temperature tolerance, silicone tubing is ideal for applications requiring precise fluid handling, such as in healthcare, pharmaceuticals, food, and beverage industries. Its inert properties make it safe for transporting sensitive fluids, and its durability ensures long-lasting performance under demanding conditions.

Choosing the right silicone tubing for a peristaltic pump involves considering factors such as tubing size, wall thickness, temperature resistance, and compatibility with specific pump models. Proper maintenance, including regular inspections for signs of wear, kinks, or blockages, is essential to ensure optimal pump performance and prevent disruptions in fluid flow. Additionally, silicone tubing’s smooth interior helps reduce bacterial build-up, making it particularly suitable for food-grade and medical applications.

JESilicone offers professional customization and production of high-quality peristaltic pump silicone tubing in a wide range of sizes (such as 13# 14# 15# 16# 17# 18# 24# 25# 35# 36# 73# 82# 86# 88# 90# 92#,etc). With over 20 years of expertise and advanced manufacturing techniques, we ensure that each tube meets the highest standards of durability and performance. Whether you need specific dimensions or unique requirements, we are committed to providing tailored solutions to suit your needs. Contact us now for more details and a competitive quote. We look forward to assisting you with your project!