Peristaltic Pump Silicone Tubing: The Ultimate Sizing & Selection Guide

Selecting and sizing silicone tubing for a peristaltic pump shouldn’t feel like guesswork. If you work in food and beverage processing or industrial dosing/water treatment, this guide gives you a clear, vendor-neutral path to decide between silicone and TPE (PharMed/Norprene-type) alternatives and to size tubing by ID, wall, RPM, and pressure for reliable, compliant flow. This article is practical engineering guidance, not regulatory or legal advice—always verify with your supplier’s certifications and your QA team.

When silicone tubing is the right choice (and when it isn’t)

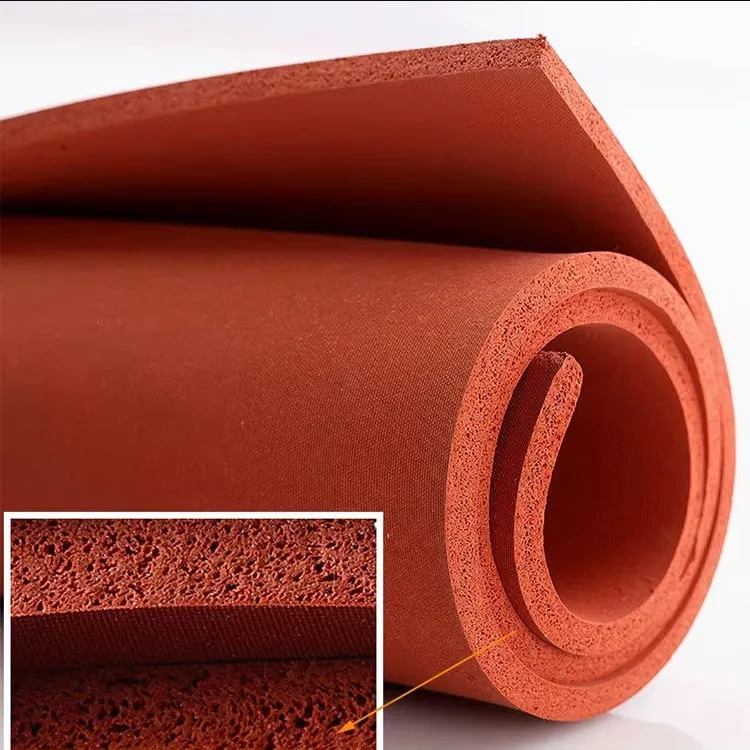

Silicone is popular in peristaltic applications because it’s flexible, easy to load, and remains compliant across a wide temperature window. In food and beverage lines, platinum-cured silicone is often favored for its low extractables and minimal taste/odor contribution, which helps protect product sensory quality. In general lab and industrial dosing, silicone’s availability, broad temperature tolerance, and straightforward handling make it a common default.

Where silicone can fall short is service life and spallation in heavy-duty peristaltic duty. Compared with pump-optimized TPEs, standard silicone tends to shed more particles (spallation) and may have shorter life under higher pressure or abrasive/oxidizing chemistries. If the process is sensitive to particulate generation, or you need long maintenance intervals with continuous duty, a peristaltic-optimized TPE or composite tube may be a better fit.

Silicone vs. TPE/PharMed/Norprene: how to decide

Think in terms of performance envelopes rather than absolutes—formulations and pumpheads differ. Still, a few patterns can guide you:

- Longevity and spallation: Many TPEs engineered for peristaltic use deliver significantly longer life and lower spallation than standard silicone. Manufacturer literature highlights long-life TPEs and composites designed to resist abrasion and compression set in pump tracks. Validate these claims in your own duty cycle with pilot runs.

- Chemical resistance and permeability: Silicone offers broad compatibility but relatively high gas permeability. TPEs and composite fluoroelastomer liners often reduce gas ingress and improve resistance to certain organics. For caustics, coagulants, and oxidants typical in water treatment, TPEs frequently hold up better.

- Temperature window: Silicone typically tolerates a broader low/high temperature range and remains soft at low temperatures, which can aid startup and loading.

- Cost of ownership: Even if silicone’s unit price is lower, frequent changeouts can drive higher labor and downtime costs. If your line is continuous or changeout access is constrained, long-life tubing can win overall.

- Caveat: Performance depends on specific grades and the pumphead geometry/occlusion. Bench-test both materials under your pressure, RPM, fluid, and temperature to see the true life and accuracy profile.

Platinum-cured vs. peroxide-cured silicone

Both are silicone elastomers, but curing chemistry affects purity and performance nuances:

- Extractables, taste, and odor: Platinum-cured (addition-cured) silicone generally exhibits lower extractables and minimal organoleptic impact, which is why it’s preferred for sensitive food and beverage dosing. Industry references describe reduced residues relative to peroxide-cured grades and better suitability where taste/odor neutrality matters. See technical guidance from silicone suppliers and bioprocessing studies, such as WACKER’s materials guide and a Saint-Gobain white paper on sterilization effects, which note mechanical and purity differences between curing systems (WACKER materials guide; Saint-Gobain sterilization white paper).

- Sterilization tolerance: Both types handle steam and EtO; platinum-cured grades often retain mechanical properties better under gamma/e-beam per cited tests (same sources above). Match the curing system to your sanitation regime.

- Typical use: In food & beverage and high-purity transfer, platinum-cured silicone is the default. Peroxide-cured can be suitable for less sensitive tasks where trace extractables aren’t critical.

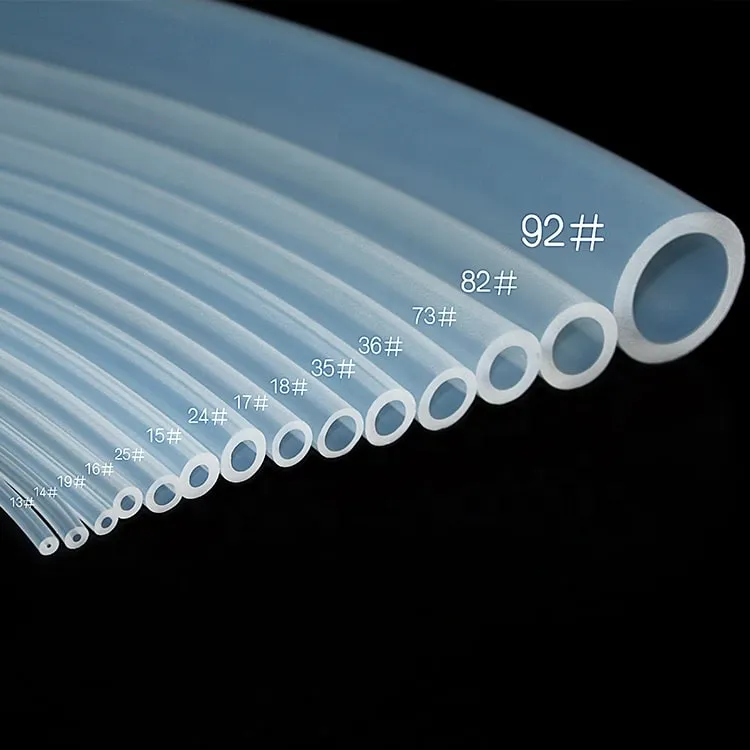

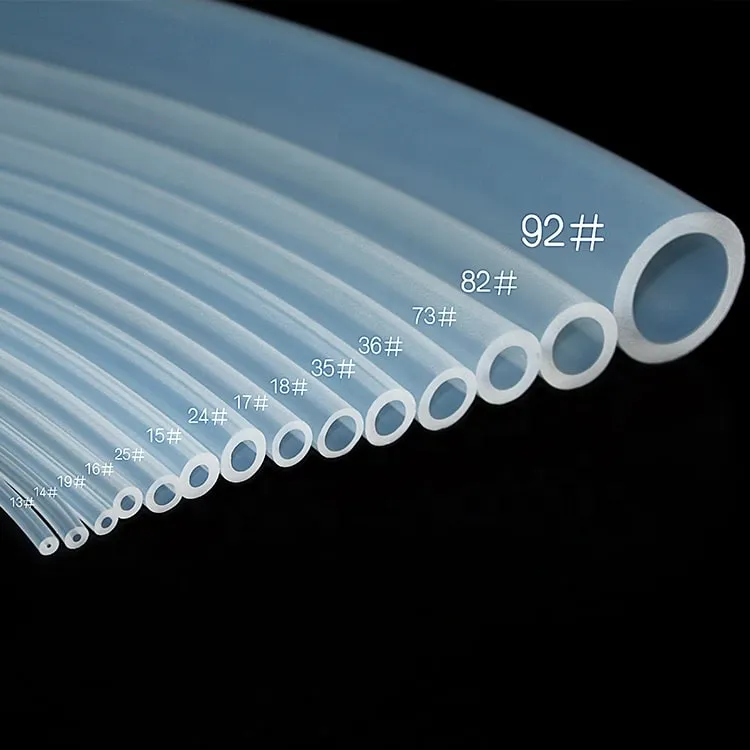

How to size tubing for target flow and pressure

At the heart of peristaltic selection is a simple relationship: Q = N × V, where Q is flow (mL/min), N is pump speed (RPM), and V is the volume per revolution. V is strongly influenced by tubing ID, wall thickness, occlusion, and pumphead geometry. OEMs publish flow tables that map tubing IDs to flow at standard RPMs for specific heads; that’s your starting point.

Sizing workflow:

1. Define requirements

- Target flow (mL/min) and control range

- Available drive RPM range (min/max)

- Expected backpressure and fluid viscosity

- Acceptable pulsation and accuracy

2.Shortlist ID by flow at mid-range RPM

Use the pump manufacturer’s flow table to find IDs that hit your target near the middle of your RPM range. Running in the middle gives headroom to adjust up/down and typically improves tube life.

3. Select wall thickness for pressure and head compatibility

Check pumphead’s approved tubing sizes (ID × wall). Thicker walls generally support higher pressure but increase stiffness; confirm that the selected wall is listed for your head and pressure.

4. Validate bend radius and routing

Ensure the minimum bend radius is respected throughout the run, especially near the pump. Tighter bends increase fatigue and can kink the line, hurting accuracy and life.

5. Prototype and calibrate

Build a test loop with your actual fluid, temperature, and backpressure. Measure real flow gravimetrically and set a correction factor in the drive (if available).

Sizing Worksheet (Example)

The following worksheet illustrates the decisions and calculations you’ll make. Replace inputs with your values, consult your pump’s flow tables, and record the selected combination.

| Step |

INPUT/ACTION |

Note |

| 1 |

Target flow Qset = 450 mL/min |

Define min/max and acceptable error (e.g., ±2%). |

| 2 |

Drive RPM range = 30–300 RPM |

Confirm controller resolution. |

| 3 |

Candidate IDs from OEM table |

Find IDs delivering ~450 mL/min at ~150 RPM. |

| 4 |

Select ID = (from table) |

Pick ID that centers RPM and minimizes pulsation. |

| 5 |

Wall options from head spec |

E.g., 1.6 mm or 2.4 mm wall; check pressure rating. |

| 6 |

Backpressure estimate = 1.5 bar |

Include filters, elevation, valves; add safety factor. |

| 7 |

Fluid viscosity = 150 cP |

Higher viscosity lowers actual flow; expect correction. |

| 8 |

Check bend radius ≥ OEM min |

Reroute or choose reinforced tubing if needed. |

| 9 |

Prototype: measure Qactual |

Gravimetric test over ≥2 min to reduce error. |

| 10 |

Correction factor CF = Qset/Qactual |

Store in drive; re-check after initial run-in. |

Why no universal “flow chart” numbers here? Because peristaltic flow depends on the specific pumphead and occlusion setting. The most accurate approach is to use the manufacturer’s flow table for your pump model and then calibrate in situ. OEM manuals from major suppliers include these tables and flow calibration menus; for example, see the 630 Du/DuN and 530 series manuals with step-by-step “Flow calibration” procedures (630 Du/DuN manual; 530 Pn/PnN manual; 530 U/UN manual).

Pressure limits, bend radius, occlusion, and tube life

- Working pressure isn’t just a material property; it’s an interaction between tube, head, and drive. For example, reinforced silicone products list high static pressure capabilities, but peristaltic working limits depend on the pumphead. Review the tubing and pump manuals together. Vendor pages provide indicative ranges—for instance, platinum-cured silicone offerings and braid-reinforced silicone lines publish size-dependent pressure figures, while TPE peristaltic tubes (e.g., long-life lines) highlight higher pump-life at given pressures (Pumpsil page; Tygon SPT-3370 IB; Tygon XL-60 PDF; PharMed BPT datasheet).

- Bend radius: Keep bends as large as practical and avoid tight routing near the pump. OEM installation guides for hose and cased pumps consistently advise maximizing bend radius to prevent kinking and early fatigue (Bredel APEX manual excerpt).

- Occlusion and loading: Over-occlusion accelerates wear and spallation; under-occlusion reduces efficiency and accuracy. Follow your pumphead manual to set the correct gap and load tubing straight, without twist, and with the recommended slack. Manufacturer manuals stress these adjustments and cleanliness of the track/rollers (501RL pumpheads manual page; 401U manual).

Compliance: what to ask your supplier (food & beverage focus)

- FDA 21 CFR 177.2600: This U.S. regulation covers rubber articles for repeated food contact, including silicone elastomers. It specifies authorized constituents and extraction tests in water and n-hexane at reflux for 7 hours, with residue limits per area. Ask for a Declaration of Compliance (DoC) and supporting test reports referencing §177.2600 (eCFR §177.2600; CFR 2024 index).

- EU 1935/2004 and GMP 2023/2006: In the EU, silicone food-contact tubing is governed by the general framework requiring materials not to endanger health, change food composition, or alter organoleptics, plus good manufacturing practice. Request a DoC to 1935/2004 and evidence of GMP controls (EC FCM legislation overview).

- EU 10/2011 plastics regulation: It does not apply to silicone elastomers; it’s plastics-specific per Article 1 on EUR-Lex. If a certificate cites 10/2011 for silicone, ask for clarification and proper basis under 1935/2004 or relevant national recommendations (EUR-Lex 10/2011 scope).

- NSF/ANSI 51: While not mandatory everywhere, certification to NSF/ANSI 51 (materials for food equipment) helps with acceptance and addresses material safety and cleanability consistent with FDA’s indirect additives framework. If your equipment falls under these expectations, request NSF/ANSI 51 certification details (NSF/ANSI 51 overview).

- Practical note: Testing simulants and conditions designed for plastics may not suit elastomers like silicone; EU technical discussions recognize the need to adapt conditions. This nuance helps explain differences in reports you’ll see from suppliers (EFSA network minutes, 2023).

Calibration procedure for flow accuracy

Most modern peristaltic drives include a “Flow calibration” function. The procedure mirrors OEM manuals and looks like this:

- Stabilize the system: Run at the target RPM with product fluid at operating temperature and normal backpressure. Let the tubing settle through initial run-in.

- Measure gravimetrically: Collect discharge into a tared container for a defined time (e.g., 120–300 seconds). Calculate Qactual = mass ÷ (density × time). Minimize evaporation and timing error.

- Compute and apply a correction factor: CF = Qset ÷ Qactual. Enter CF into the drive’s calibration menu where supported. Re-verify at a few setpoints for linearity. OEM manuals describe this workflow in detail (e.g., the 630 Du/DuN and 530 series “Flow calibration” sections: 630 Du/DuN manual; 530 Pn/PnN manual; 530 U/UN manual).

Two quick application examples

- Beverage syrup dosing: A plant needs 300–500 mL/min of viscous syrup with strict taste/odor limits. Platinum-cured silicone is selected for organoleptic neutrality, sized using OEM flow tables to hit ~400 mL/min at mid-range RPM. Backpressure from small-bore nozzles reduces actual flow, so the team performs gravimetric calibration and enters a correction factor in the drive. Tube routing respects the minimum bend radius to prevent kinking, and occlusion is set per the pumphead manual.

- Water treatment coagulant dosing: Operators dose coagulants continuously at 100–200 mL/min under modest backpressure. Standard silicone showed frequent changeouts and visible spallation in filters. A peristaltic-optimized TPE alternative is trialed, demonstrating longer life and cleaner operation. Chemical compatibility is confirmed via supplier data; occlusion is tuned to reduce compression fatigue, and replacement intervals are set based on observed hours-to-failure.

Maintenance and replacement cadence

Inspect tubing on a schedule aligned with your duty cycle. Look for:

- Visual wear: whitening, cracking, or permanent flattening in the track

- Spallation: particles downstream or darkening in filters

- Flow drift: increasing correction factor needed over time

Cleaning/CIP should match the tubing’s material and curing system. After CIP/SIP, re-check calibration—thermal cycles can change compliance. Keep bends gentle, avoid unnecessary valves near the pump, and load tubing straight with the correct occlusion. These habits reduce fatigue and can extend life.

Closing thoughts: You don’t have to choose silicone or TPE in a vacuum. Start with your process priorities—taste/odor neutrality, longevity, chemical resistance—then use OEM flow tables to shortlist ID and wall combinations, prototype under real conditions, and calibrate. Document compliance (FDA §177.2600; EU 1935/2004; NSF/ANSI 51 where relevant) and maintain sensible routing and occlusion. Do that, and your peristaltic line will run accurately and with fewer surprises.