What Are the Benefits of Silicone Milk Tubing?

Silicone milk tubing offers numerous benefits in dairy applications. The material ensures safety and compliance with food standards. Silicone tubing provides exceptional durability and flexibility. The transparency of silicone tubing allows for easy monitoring and inspection. Temperature resistance enhances the reliability of silicone tubing in diverse conditions. As a specialist in silicone industry, JESilicone will show you three key benefits of using silicone milk tube in dairy operations.

Benefit 1:Safety and Compliance

Food-Grade Material

Silicone milk tube offers a high level of safety in dairy operations. Manufacturers use FDA-approved materials to produce silicone milk tube. This ensures that the tube meets strict food safety standards. The non-toxic properties of silicone milk tube make it ideal for transporting milk. No harmful chemicals leach into the milk. This guarantees the purity of the product.

Non-Toxic Properties

Silicone milk tubing possesses non-toxic properties. These properties ensure that no harmful substances contaminate the milk. The material used in silicone milk tube does not react with milk fat or other components. This prevents any chemical interaction that could compromise milk quality. Studies have shown that silicone does not release siloxanes into milk or formula within six hours. This further supports the safety of silicone milk tube in dairy applications.

Compliance with Food Standards

Silicone milk tube complies with various food safety standards. This compliance ensures that the tube is safe for use in dairy processing. Manufacturers adhere to guidelines set by regulatory bodies. These guidelines ensure that silicone milk tube maintains its integrity during use. The compliance with food standards provides peace of mind for dairy operators. This guarantees that the milk remains uncontaminated throughout the process.

Learn more about food-grade silicone tubing

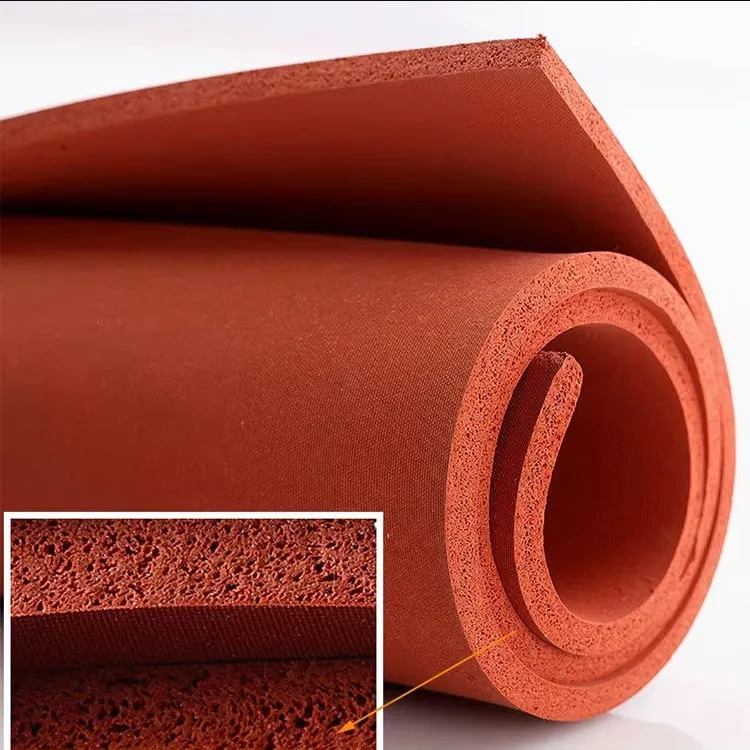

Durability

Silicone milk tubing offers exceptional durability. The material withstands the rigors of daily dairy operations. This durability ensures that the tube remains functional over time. Silicone milk tube resists wear and tear. This resistance makes it a reliable choice for dairy applications.

Resistance to Wear and Tear

Silicone milk tube exhibits strong resistance to wear and tear. The material does not crack or degrade easily. This resistance ensures that the tube maintains its functionality. Dairy operations often involve harsh conditions. Silicone milk tube withstands these conditions without compromising performance. This makes it an excellent choice for long-term use.

Longevity in Dairy Operations

Silicone dairy tubing provides longevity in dairy operations. The material's durability ensures that the tube lasts for extended periods. This longevity reduces the need for frequent replacements. Dairy operators benefit from reduced maintenance costs. The consistent performance of silicone milk tube enhances operational efficiency. This makes it a valuable asset in dairy processing.

Flexibility and Ease of Use

Installation and Handling

Silicone milk tube offers exceptional flexibility, making installation straightforward. The lightweight nature of silicone milk tube allows for easy handling during setup. Dairy operators appreciate the ease with which silicone milk tube can be maneuvered into place.

Lightweight Nature

The lightweight nature of silicone milk tube reduces strain during installation. Workers find silicone milk tube easier to manage compared to heavier alternatives. This feature enhances efficiency in dairy operations.

Easy to Cut and Fit

Silicone milk tube is easy to cut and fit to specific requirements. Dairy facilities benefit from the adaptability of silicone milk tube. Customization of silicone milk tube ensures optimal performance in various setups.

Versatility

Silicone milk tube demonstrates remarkable versatility in dairy applications. The compatibility of silicone milk tube with different equipment enhances its utility. Dairy operators value the seamless integration of silicone milk tube into existing systems.

Compatibility with Various Equipment

Silicone milk tube works well with a wide range of dairy equipment. The design of silicone milk tube ensures smooth operation without compatibility issues. This compatibility makes silicone milk tube a preferred choice in diverse dairy environments.

Adaptability to Different Dairy Processes

Silicone milk tube adapts to various dairy processes with ease. The resilience of silicone milk tube supports its use in multiple applications. Dairy operations benefit from the consistent performance of silicone milk tube across different tasks.

Transparency and Monitoring

Visual Inspection

Silicone milk tubing offers excellent transparency. Dairy operators can easily detect blockages within the tubing. The clear material allows for quick identification of any obstructions. This feature helps maintain a smooth milk flow.

Easy Detection of Blockages

The transparent nature of silicone milk tubing aids in spotting blockages. Operators can visually inspect the tubing for any clogs. This ability ensures prompt action to resolve issues. Quick detection minimizes disruptions in dairy operations.

Monitoring Milk Flow

Silicone milk tubing allows operators to monitor milk flow effectively. The clear tubing provides a direct view of the milk's movement. Operators can ensure consistent flow rates during processing. This monitoring enhances quality control in dairy facilities.

Aesthetic Appeal

Silicone milk tubing contributes to a clean and professional look. The tubing's clarity adds an aesthetic value to dairy facilities. The appearance of the tubing reflects high standards of hygiene. This visual appeal supports a positive image for dairy operations.

Clean and Professional Look

The sleek design of silicone milk tubing offers a polished appearance. Dairy facilities benefit from the tubing's neat presentation. The professional look aligns with industry standards. This feature enhances the overall environment of dairy operations.

Enhancing Dairy Facility Appearance

Silicone milk tubing improves the visual appeal of dairy facilities. The transparent material complements modern equipment. The tubing's appearance boosts the facility's image. An attractive setup fosters confidence in product quality.

Temperature Resistance

High-Temperature Tolerance

Silicone milk tubing exhibits remarkable high-temperature tolerance. The material withstands temperatures up to 200°C. This makes silicone tubing suitable for pasteurization processes. Dairy operations rely on pasteurization to ensure milk safety. Silicone tubing maintains its integrity under heat. The tubing does not degrade or lose flexibility. This reliability ensures consistent performance during high-temperature applications.

Suitable for Pasteurization Processes

Pasteurization requires materials that endure high temperatures. Silicone milk tubing meets these demands effectively. The tubing's resistance to heat prevents deformation. This quality ensures the safe processing of milk. Dairy facilities benefit from the tubing's durability in pasteurization.

Maintaining Integrity Under Heat

Silicone milk tubing retains its structure under extreme heat. The material does not crack or become brittle. This stability ensures long-term use in dairy operations. The tubing's ability to maintain integrity enhances operational efficiency. Dairy operators trust silicone tubing for reliable performance.

Cold Resistance

Silicone milk tubing also demonstrates excellent cold resistance. The material remains flexible at low temperatures. This property is crucial for refrigerated conditions. Dairy operations often involve storage and transportation in cold environments. Silicone tubing performs well in these settings.

Performance in Refrigerated Conditions

Refrigerated conditions require materials that resist brittleness. Silicone milk tubing excels in such environments. The tubing maintains flexibility and functionality. This performance ensures the smooth flow of milk. Dairy facilities rely on silicone tubing for consistent operation in cold storage.

Preventing Brittle Cracking

Silicone milk tubing prevents brittle cracking at low temperatures. The material's elasticity remains intact. This resistance reduces the risk of leaks or blockages. Dairy operators benefit from the tubing's durability in cold conditions. The prevention of cracking enhances the safety and efficiency of dairy processes.