Food-grade silicone tubing refers to a type of flexible, durable tube made from high-quality silicone rubber. This material meets stringent safety and hygiene standards for use in food and beverage applications. These materials ensure that no harmful chemicals leach into consumables. Food safe silicone tubes offer non-toxic, odorless, and tasteless properties, making them ideal for maintaining the purity of food and beverages.

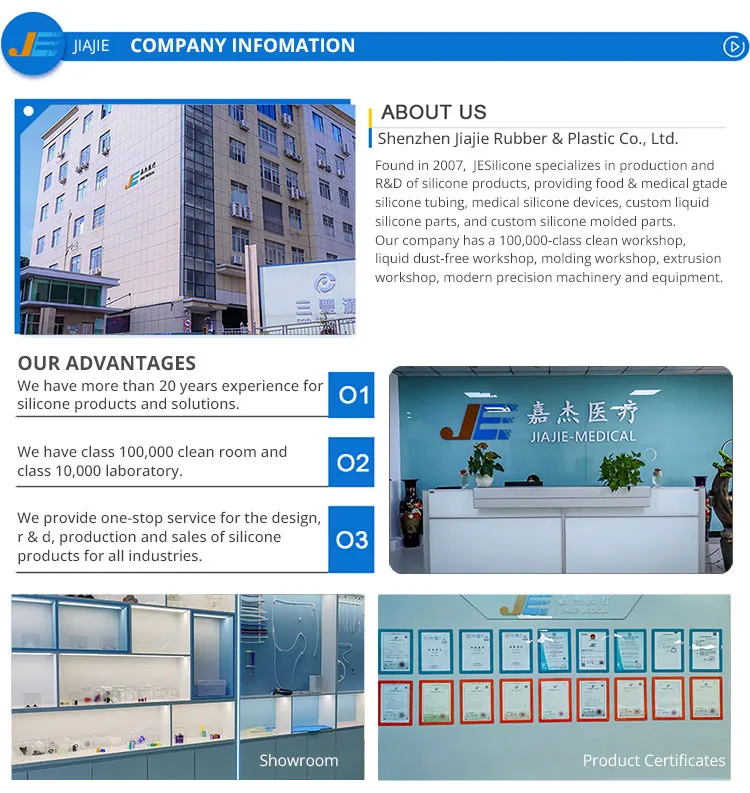

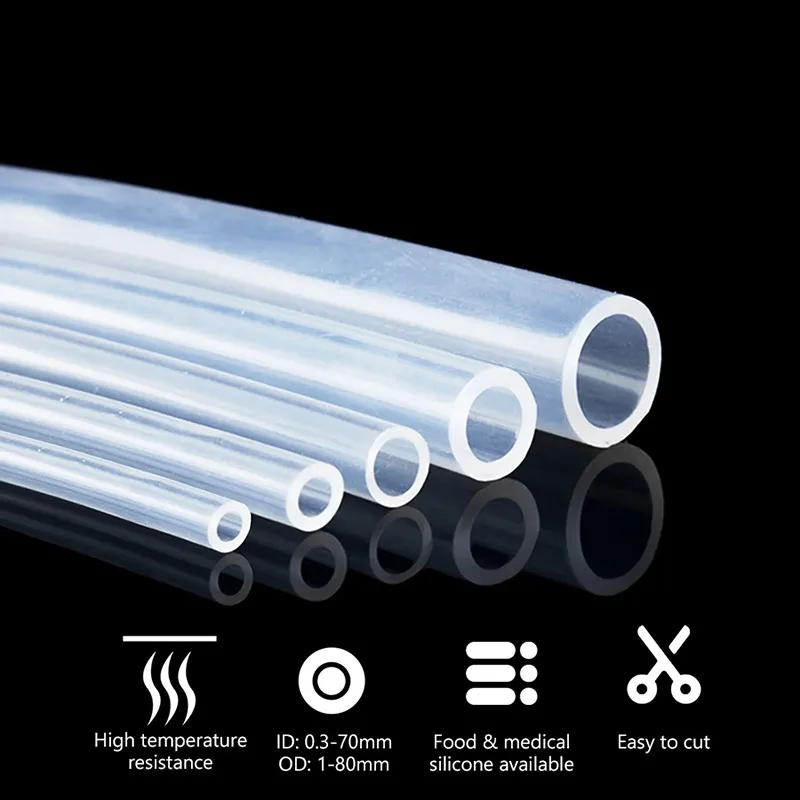

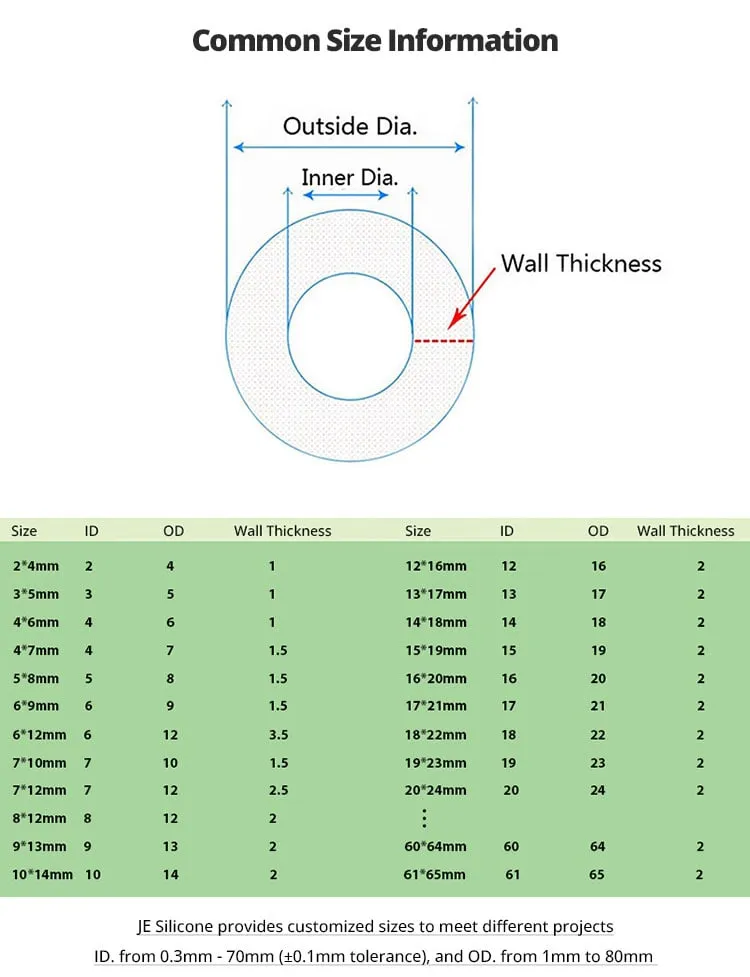

JESilicone provides professional custom silicone tube service, we can custom inner diameters from 0.3mm to 70mm, and outer diameters from 1mm to 80mm, which can meet most customer’s specific requirements.

Key Applications of Food Grade Silicone Hoses

1. Dairy & Milk Processing

Food-grade silicone tubing ensures hygienic transfer of milk, cream, and dairy products, resisting bacterial buildup and harsh CIP cleaning chemicals. Its smooth interior prevents residue accumulation, complying with 3-A Sanitary Standards for direct contact with sensitive liquids like raw milk and whey.

2. Brewery & Winemaking

Ideal for high-temperature wort, beer, and wine transfers, these hoses withstand boiling liquids and resist alcohol, acids, and carbonation. Non-reactive properties preserve flavor integrity, while flexibility suits cramped brewery setups.

3. Beverage Production

From carbonated sodas to acidic juices, silicone tubes prevent flavor transfer and handle pressurized lines. Odorless and non-toxic, they meet FDA standards for direct contact with sugary syrups and concentrates.

4. Food Manufacturing

Durable in high-heat frying oil transfers and viscous food processing (sauces, purees), these hoses resist steam sterilization and fats. USP Class VI certification ensures safety for ingredient conveying.

5. Pharmaceutical & Nutraceutical

Autoclavable and chemically inert, platinum-cured silicone tubing safely transports sterile drugs, vaccines, and supplements. Complies with USP Class VI and FDA guidelines for critical fluid handling.

6. Coffee/Espresso Machines

Heat-resistant tubing delivers steam and boiling water in commercial coffee systems without leaching. NSF-certified for food safety, it withstands daily high-pressure use in cafes and restaurants.

7. Agriculture & Food Packaging

Used in bottling lines for water, sauces, and condiments, these hoses maintain hygiene during filling and capping. Aseptic packaging systems rely on their smooth surfaces to prevent contamination risks.

Characteristics of Food Safe Silicone Tubing

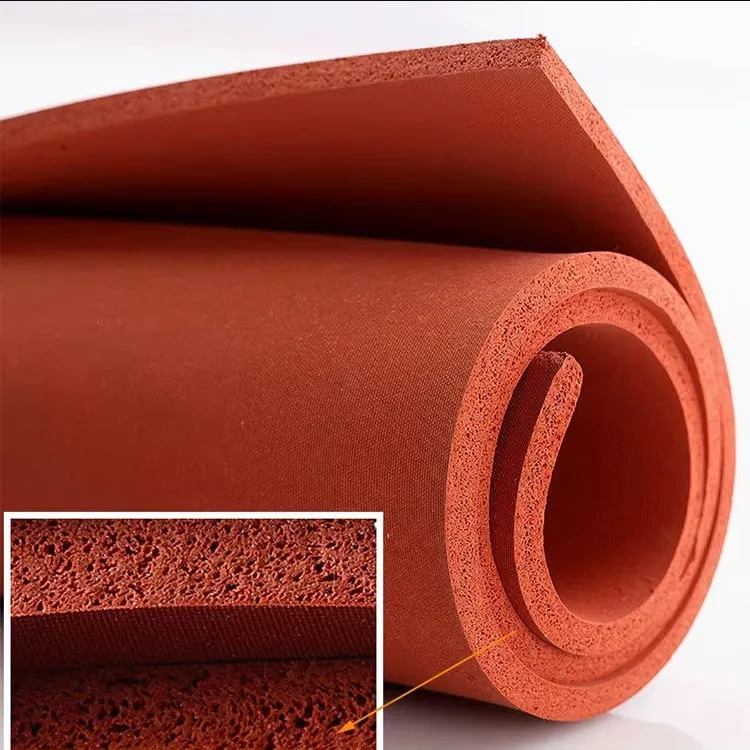

1. Material Composition

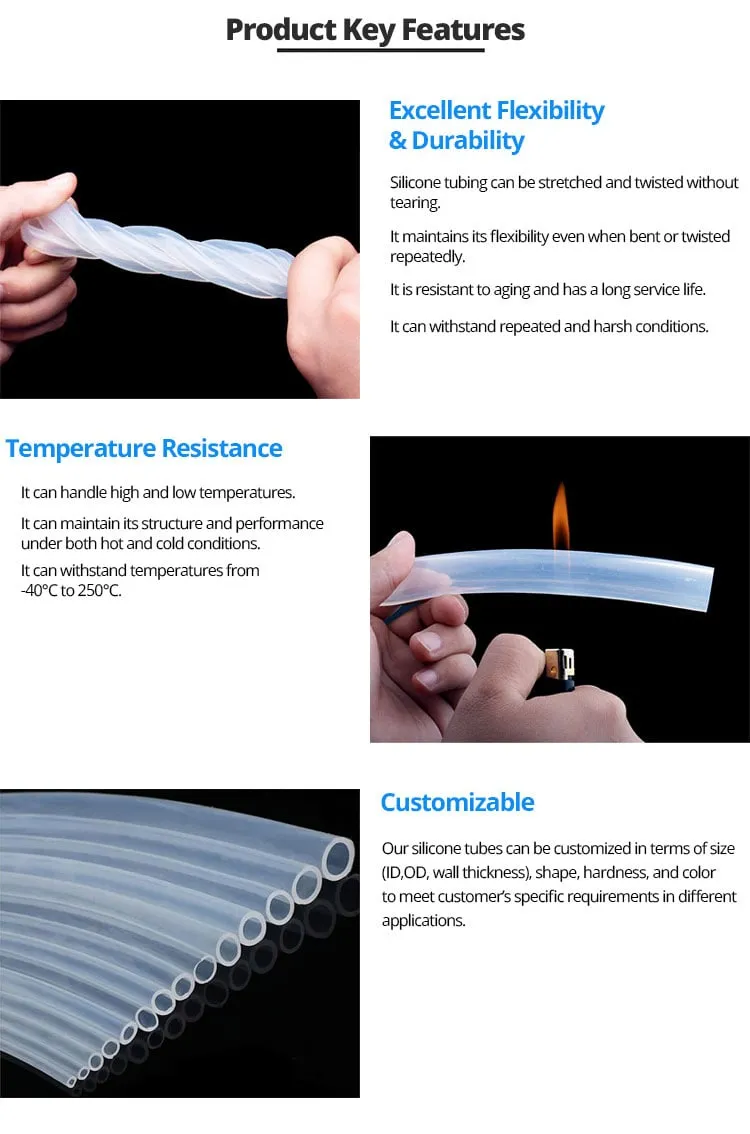

Silicone Properties: Food safe silicone tubes consist of high-quality silicone rubber. This material exhibits excellent flexibility and durability. The silicone used in these tubes does not leach harmful chemicals into food or beverages. This property ensures the safety and purity of consumables. The non-toxic nature of silicone makes it ideal for food and beverage applications.

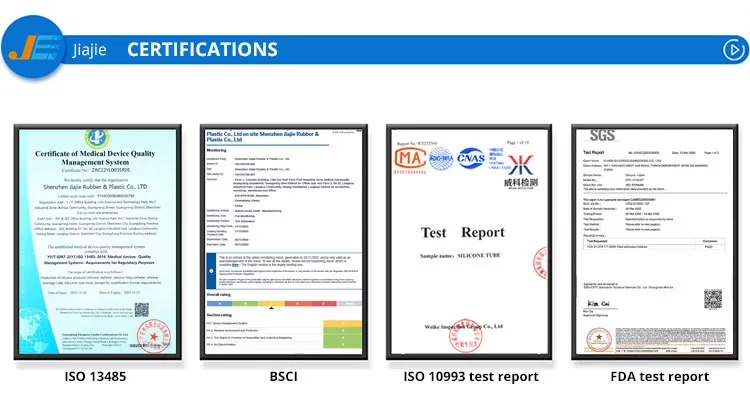

Food Safety Standards: Food-grade silicone tubes meet stringent food safety standards. These tubes comply with FDA regulations, ensuring their suitability for contact with food. The NSF-51 certification further guarantees the quality and safety of the tubing. Compliance with these standards provides assurance to users about the safety of the materials.

2. Physical Properties

Flexibility and Durability: Food-grade silicone tubes offer exceptional flexibility. This flexibility allows the tubing to bend without breaking. The durable nature of silicone ensures a long lifespan for the tubing. Users can rely on these tubes for various applications without frequent replacements.

Temperature Resistance: Silicone tubing can withstand extreme temperature variations. High-temperature resistance makes these tubes suitable for both hot and cold applications. Unlike plastic or rubber tubing, silicone does not degrade under extreme conditions. This property ensures consistent performance in diverse environments.

3. Chemical Properties

Non-reactivity: Food grade silicone tubes exhibit non-reactive properties. These tubes do not react with food or beverages, maintaining the integrity of the contents. The inert nature of silicone ensures that no chemical reactions occur during use. This characteristic is crucial for preserving the quality of consumables.

Odor and Taste Neutrality: Silicone tubing does not impart any odor or taste to food or beverages. This neutrality is essential for maintaining the original flavors of consumables. Users can trust that the tubing will not alter the sensory properties of their products. This feature makes food grade silicone tubes highly desirable in the food and beverage industry.

Key Benefits of Food Grade Silicone Tubing

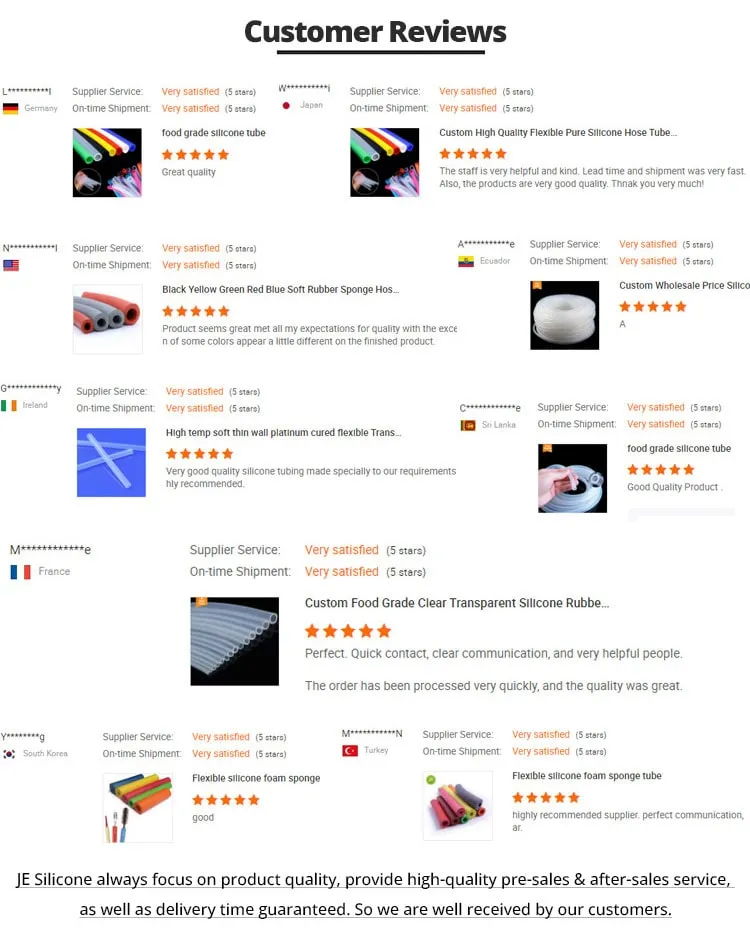

Safety and Compliance

FDA and Other Regulatory Approvals: Food grade silicone tube meets stringent regulatory requirements. The FDA approves these products for food contact applications. The NSF-51 certification further ensures safety and quality. These approvals provide confidence in the use of silicone tubing for food and beverage handling.

Non-toxic and Hypoallergenic: Silicone tubing offers non-toxic properties. This material does not leach harmful chemicals into consumables. The hypoallergenic nature of silicone makes it suitable for sensitive applications. Users can trust silicone tubing for safe and clean operations.

Versatility

Wide Range of Applications: Food grade silicone tubing serves various industries. The food and beverage sector relies on silicone tubing for safe processing. Medical and pharmaceutical fields use silicone tubing for sterile applications. Home and industrial users also benefit from the flexibility and reliability of silicone tubing.

Compatibility with Various Substances: Silicone tubing shows compatibility with a wide range of substances. This tubing handles both acidic and alkaline solutions without degradation. The material remains stable when exposed to oils, fats, and other chemicals. This versatility makes silicone tubing a preferred choice for diverse applications.

Durability and Longevity

Resistance to Wear and Tear: Silicone tubing exhibits high resistance to wear and tear. The durable nature of silicone ensures long-lasting performance. Users experience fewer replacements and lower maintenance costs. This durability proves beneficial in demanding environments.

Cost-effectiveness Over Time: Silicone tubing offers cost-effectiveness over time. The initial investment in high-quality silicone tubing pays off through reduced maintenance. The long lifespan of silicone tubing minimizes the need for frequent replacements. Users benefit from the overall cost savings and reliable performance.