A Comprehensive Guide to Silicone Foam Tubes and Their Uses

Silicone foam tubes serve as essential components in various industries. These tubes provide sealing, cushioning, vibration dampening, and thermal insulation. Industries such as automotive, aerospace, and electronics rely on silicone foam tubes for their excellent properties. The global market for silicone foam is projected to reach USD 1.2 billion by 2027, growing at a CAGR of 6.7%. This guide aims to offer a comprehensive understanding of silicone foam tubes, highlighting their importance and diverse applications.

What are Silicone Foam Tubes?

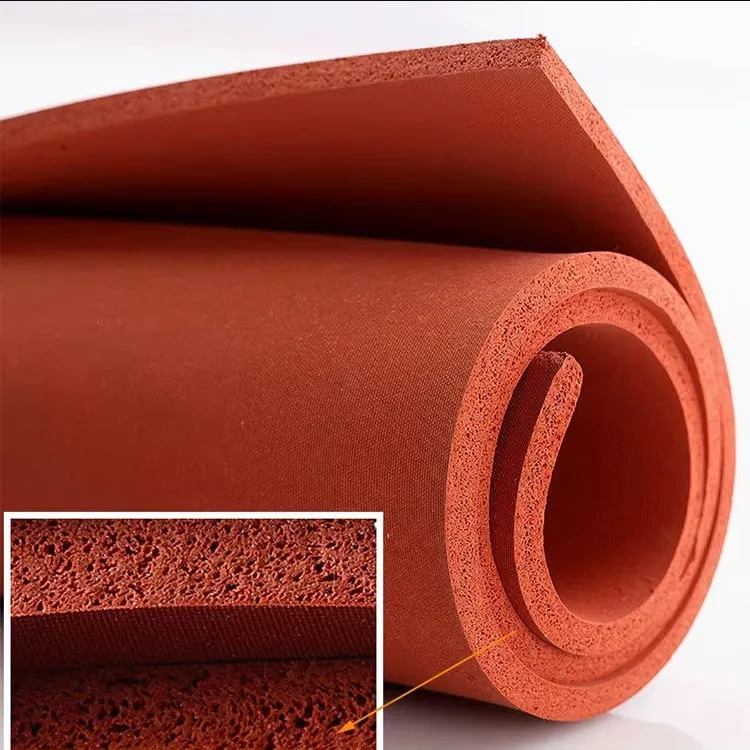

A silicone foam tube is a type of tubing crafted from silicone foam material. This material exhibits lightweight, compressible, and flexible characteristics. Excellent thermal and electrical insulation properties define silicone foam. Resistance to water, chemicals, and UV radiation further enhances its suitability for diverse applications. The closed-cell structure of the silicone foam tube ensures that tiny bubbles formed during heat curing do not connect, providing superior sealing and insulating capabilities.

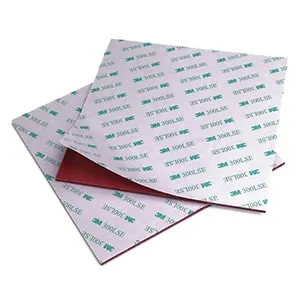

Manufacturing Process of Silicone Sponge Tubing

The manufacturing process of a silicone sponge tube involves several key steps. Initially, raw silicone material undergoes mixing with blowing agents. This mixture then enters an extrusion machine where it shapes into tubes. The extruded tubes proceed to a heat-curing stage. During this phase, the material expands, creating the closed-cell structure. The final product undergoes quality checks to ensure compliance with industry standards.

Key Properties of Silicone Foam Sponge Tubes

- Physical Properties: Silicone foam tubes exhibit lightweight, high flexibility, and compressibility. The closed-cell structure provides excellent cushioning and shock absorption.

- Chemical Properties: Silicone foam tubes can resist a wide range of chemicals, such as oils, solvents, and other harsh substances. This resistance ensures durability and longevity in demanding environments.

- Thermal Properties: Silicone foam tubes provide effective thermal insulation, maintaining stability across a broad temperature range. Resistance to extreme temperatures makes them suitable for both high-heat and low-temperature applications.

Silicone Foam Tube Types: Open-Cell vs. Closed-Cell

Open-cell silicone foam tubes feature interconnected cells. These cells allow the absorption and release of liquids or gases. This structure provides superior cushioning and flexibility. Open-cell tubes excel in applications requiring breathability and moisture management. The lightweight nature of open-cell foam enhances its usability in various industries.

Closed-cell silicone foam tubes possess a denser and less porous structure. This design makes them impermeable to air or water. Closed-cell tubes offer rigidity and stability. These tubes provide excellent sealing and insulation properties. The closed-cell structure ensures minimal fluid absorption, making them ideal for demanding environments.

Applications of Silicone Foam Tubes

Sealing and Insulation

Silicone foam tubes play a crucial role in sealing and insulation within various industries. The automotive sector uses these tubes for gasket and sealing purposes. The closed-cell structure of the silicone foam tube ensures effective protection against moisture, dust, and other environmental elements. Construction industries also benefit from the superior sealing properties of silicone foam tubes. These tubes provide excellent thermal insulation, making them ideal for HVAC systems and electrical enclosures.

Vibration Dampening

Industries such as aerospace and electronics rely on silicone foam tubes for vibration dampening. The high compressibility and flexibility of the silicone foam tube absorb vibrations and shocks. This property helps protect sensitive components and machinery from damage. The use of silicone foam tubes in vibration dampening applications enhances the longevity and reliability of equipment.

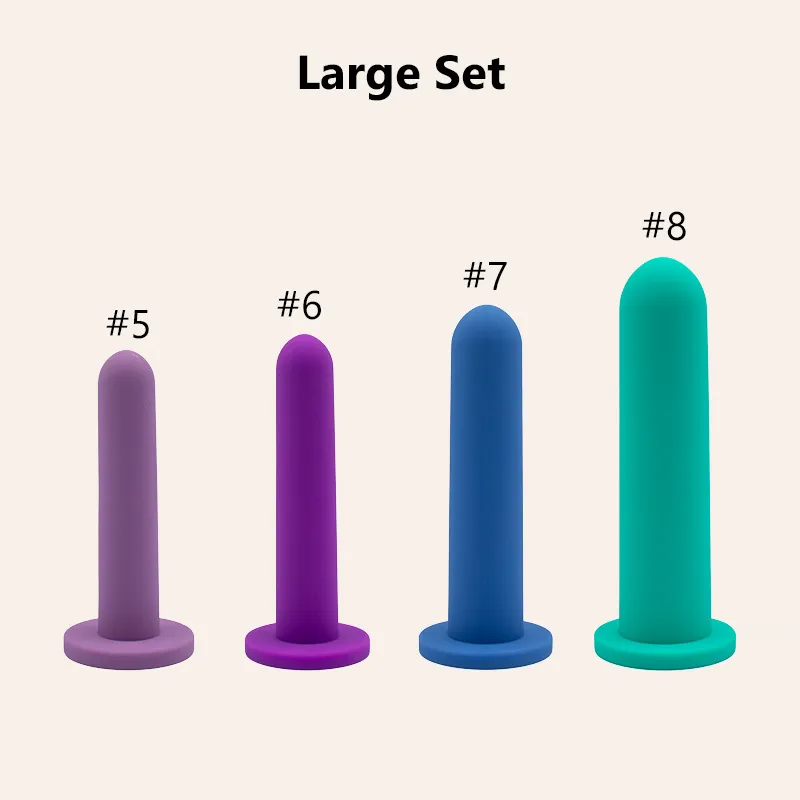

Medical Devices

Silicone foam tubes find extensive use in medical devices. The biocompatibility of the silicone foam tube makes it suitable for various medical applications. These tubes provide cushioning and support in devices such as catheters and drainage tubes. The flexibility and softness of the silicone foam tube ensure patient comfort and safety.

Prosthetics and Orthotics

Prosthetics and orthotics benefit significantly from the use of silicone foam tubes. The lightweight and compressible nature of the silicone foam tube provides excellent cushioning and support. These tubes enhance the comfort and functionality of prosthetic limbs and orthopedic braces. The durability and resistance to environmental factors ensure long-lasting performance in medical applications.

Household Items

Silicone foam tubes are commonly used in household items. The thermal insulation properties of the silicone foam tube make it ideal for use in appliances such as refrigerators and ovens. These tubes also provide cushioning and sealing in various household products. The versatility and flexibility of the silicone foam tube make it suitable for a wide range of consumer applications.

Automotive Uses

The automotive industry extensively uses silicone foam tubes for various applications. These tubes provide sealing and insulation in vehicle components such as doors and windows. The vibration dampening properties of the silicone foam tube help reduce noise and improve ride comfort. High-density silicone foam tubes offer durability and stability, making them ideal for use in demanding automotive environments.

Benefits of Using Silicone Foam Tubes

Resistance to Environmental Factors

Silicone foam tubes exhibit exceptional resistance to various environmental factors. These tubes withstand exposure to moisture, dust, and other contaminants. This resistance ensures reliable performance in harsh conditions. The automotive and aerospace industries benefit significantly from this property. Sealing applications in these sectors rely on the durability of silicone foam tubes.

Low Maintenance Requirements

Silicone foam tubes require minimal maintenance. The robust nature of the material reduces the need for frequent replacements. Industries such as electronics and construction appreciate the low upkeep demands. This characteristic translates to cost savings over time. The longevity of silicone foam tubes further enhances their appeal.

Adaptability to Different Applications

Silicone foam tubes adapt to a wide range of applications. The flexibility of the material allows for use in diverse settings. Electrical enclosures and HVAC systems benefit from the thermal insulation properties. Appliances like refrigerators and ovens also utilize silicone foam tubes. The adaptability of these tubes makes them indispensable across various industries.

Customization Options

Silicone foam tubes offer extensive customization options. Manufacturers can tailor the density and hardness to meet specific requirements. This versatility ensures optimal performance in different scenarios. Medical devices and consumer products often require customized solutions. The ability to modify silicone foam tubes enhances their utility in specialized applications.

Conclusion

Silicone foam tubes offer versatile solutions for insulation, protection, and cushioning. These tubes excel in various applications due to their high-temperature resistance, compression set resistance, and excellent thermal and electrical insulation properties. Industries such as automotive, aerospace, and electronics rely on silicone foam tubes for effective sealing and protection against environmental elements. The adaptability and durability of silicone foam tubes make them indispensable across multiple sectors. Exploring further applications and innovations in silicone foam technology can unlock new possibilities and enhance performance in diverse fields.