Unveiling the Superiority of Food-Grade Silicone Tubing: A 20+ Year Manufacturer Guide to Safety & Performance

Table of Contents

1. Introduction

1.1 Overview of Food-Grade Silicone Tubing

1.2 Why Choose Food-Grade Silicone Tubing?

2. What is Food-Grade Silicone Tubing?

2.1 Composition and Manufacturing Process

2.2 FDA Approval and Regulatory Compliance

3. Key Features of Food-Grade Silicone Tubing

3.1 Non-Toxicity and Safety

3.2 Durability and Flexibility

3.3 Temperature Resistance

3.4 Chemical Resistance

3.5 Easy to Clean and Maintain

4. Applications of Food-Grade Silicone Tubing

4.1 Food and Beverage Industry

4.2 Medical and Pharmaceutical Applications

4.3 Biotechnology and Laboratories

4.4 Other Industrial Uses

5. How to Choose the Right Food-Grade Silicone Tubing

5.1 Factors to Consider: Size, Thickness, and Strength

5.2 Choosing the Right Certifications and Compliance

5.3 Comparing Food-Grade Silicone with Other Tubing Materials

6. Advantages of Working with a Reliable Silicone Tubing Manufacturer

6.1 Importance of Quality Control and Compliance

6.2 Customization Options for Your Business Needs

6.3 Why Choose JE Silicone for Food-Grade Silicone Tubing?

7. Conclusion

7.1 Recap of Key Benefits

7.2 Making the Right Choice for Your Application

Introduction

Overview of Food-Grade Silicone Tubing

Food-grade silicone tubing is a versatile and highly durable material used in various industries, most notably in food processing, pharmaceuticals, and medical applications. It is made from high-quality silicone rubber, which is non-toxic, flexible, and resistant to extreme temperatures. With over 20 years of industry experience, we specialize in producing food-grade silicone tubing that meets strict quality standards and ensures the safety of your processes.

Why Choose Food-Grade Silicone Tubing?

Silicone tubing has become the preferred choice in many applications due to its excellent durability, flexibility, and non-toxic properties. It is compliant with food safety regulations such as FDA standards, making it ideal for use in food and beverage manufacturing. The tubing also offers outstanding chemical resistance and is highly resistant to wear, making it a long-lasting and reliable solution.

What is Food-Grade Silicone Tubing?

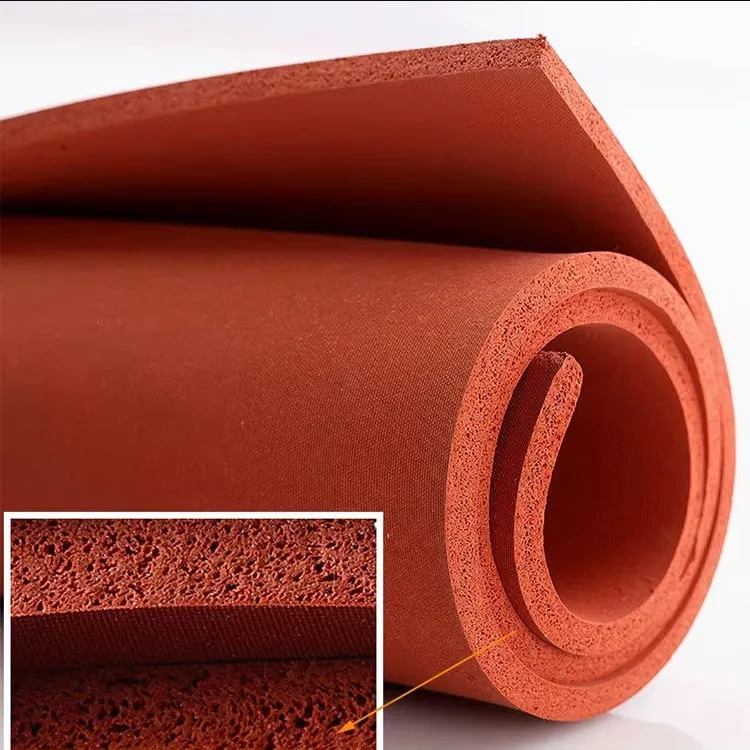

Composition and Manufacturing Process

Food-grade silicone tubing is made from high-quality, non-toxic silicone that is specifically formulated to meet industry standards for food safety. The manufacturing process involves precision molding and curing, ensuring the product meets the required strength, flexibility, and chemical resistance.

FDA Approval and Regulatory Compliance

To ensure safety, food-grade silicone tubing must comply with strict regulatory standards. FDA approval is essential for ensuring that the material is safe for direct food contact. Our silicone tubing is manufactured to meet these guidelines, offering peace of mind that your processes are safe and compliant.

Key Features of Food-Grade Silicone Tubing

Non-Toxicity and Safety

Food-grade silicone is free of harmful chemicals, making it safe for direct contact with food and beverages. Unlike other materials, silicone does not leach harmful substances, ensuring the integrity of your products.

Durability and Flexibility

Silicone tubing is known for its exceptional durability, maintaining its flexibility even in extreme conditions. Whether exposed to high or low temperatures, it will not crack or degrade easily.

Temperature Resistance

Food-grade silicone can withstand a wide temperature range, from as low as -60°C to as high as 250°C. This makes it suitable for applications that involve hot liquids, freezing temperatures, or high heat environments.

Chemical Resistance

Silicone tubing is resistant to a variety of chemicals, including acids, alkalis, and solvents, ensuring that it will not degrade or affect the quality of your product.

Easy to Clean and Maintain

One of the major advantages of silicone tubing is its ease of cleaning. It can be sterilized or autoclaved, making it ideal for sanitary applications such as food and medical industries.

Applications of Food-Grade Silicone Tubing

Food and Beverage Industry

Silicone tubing plays a crucial role in the food industry, where it is used for fluid transport, dispensing systems, and more. Its non-toxic and flexible nature makes it an ideal material for conveying liquids without contamination.

Medical and Pharmaceutical Applications

In medical devices and pharmaceutical manufacturing, food-grade silicone tubing is used for drug delivery systems, intravenous (IV) lines, and other critical applications. Its biocompatibility and resistance to degradation ensure reliable performance.

Biotechnology and Laboratories

Silicone tubing is used in laboratory settings where sterility and resistance to chemicals are paramount. It is employed in a variety of research applications, including microbiology and biochemistry.

Other Industrial Uses

Beyond food and medical uses, silicone tubing is also utilized in automotive, electronics, and manufacturing industries due to its resilience and versatility.

How to Choose the Right Food-Grade Silicone Tubing

Factors to Consider: Size, Thickness, and Strength

Selecting the right dimensions is crucial for ensuring proper fluid flow and durability.

Choosing the Right Certifications and Compliance

Businesses must verify that the tubing meets relevant safety and compliance standards before use.

Comparing Food-Grade Silicone with Other Tubing Materials

Silicone tubing outperforms PVC and rubber alternatives in safety, longevity, and environmental impact.

Advantages of Working with a Reliable Silicone Tubing Manufacturer

Importance of Quality Control and Compliance

Manufacturers must adhere to strict quality control protocols to ensure product safety and consistency.

Customization Options for Your Business Needs

Custom silicone tubing solutions help businesses meet specific operational requirements.

Why Choose Our Company for Food-Grade Silicone Tubing?

With over 20 years of experience, we specialize in high-quality, customized silicone tubing solutions tailored to your needs.

Conclusion

Recap of Key Benefits

Food-grade silicone tubing offers unmatched safety, durability, and versatility for food, medical, and industrial applications.

Making the Right Choice for Your Application

By selecting high-quality silicone tubing from a reputable manufacturer, businesses can ensure compliance, reliability, and long-term performance.