Silicone Mixing Techniques and Guide

Silicone mixing is a critical process in many industrial applications,including the medical,food & beverage, automotive, and consumer goods industries. Silicone materials are widely used in these fields due to their durability, flexibility, and resistance to extreme temperatures. Proper rubber mixing is essential to obtain high-quality silicone products. This article comprehensively explores the techniques and principles of silicone rubber mixing and will detail all aspects of silicone mixing to help you understand and master this important technology.

What Is Silicone?

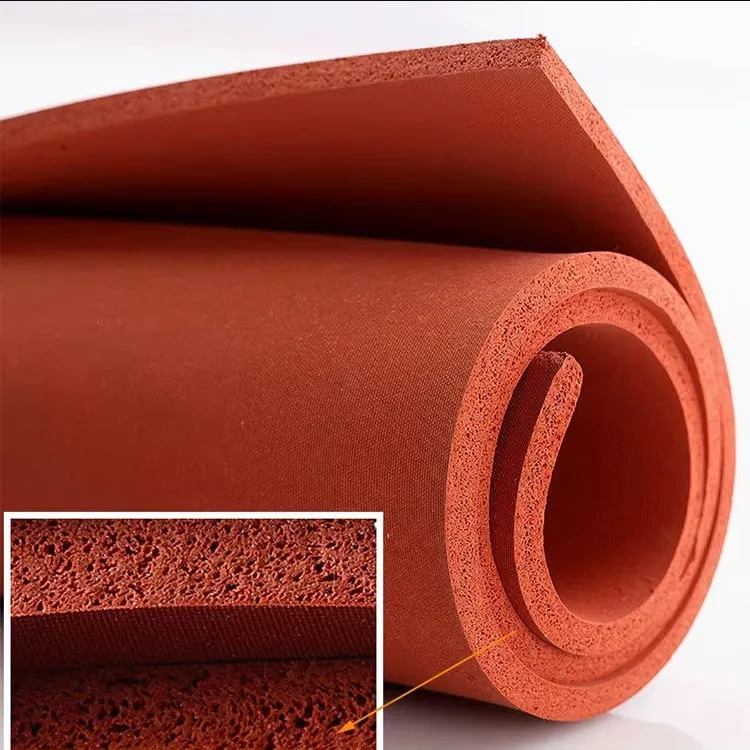

Silicone is a synthetic polymer composed of silicon, oxygen, carbon, and hydrogen atoms. It is known for its its flexibility, heat resistance, and stability. Unlike many other polymers, silicone remains stable across a wide range of temperatures, making it suitable for both high-temperature and low-temperature applications.

Key Properties Of Silicone

- Flexibility and Elasticity: Maintains flexibility even at low temperatures and does not become brittle.

- Thermal Stability: Remains stable and retains its properties over a wide temperature range (-60°C to +250°C).

- Chemical Resistance: Resistant to water, oxidation, and many chemicals, making it suitable for harsh environments.

- Biocompatibility: Safe for use in medical and food applications.

- Electrical Insulation: Excellent electrical insulating properties, ideal for electronic applications.

- UV and Weather Resistance: Resistant to UV radiation and weathering, making it durable for outdoor use.

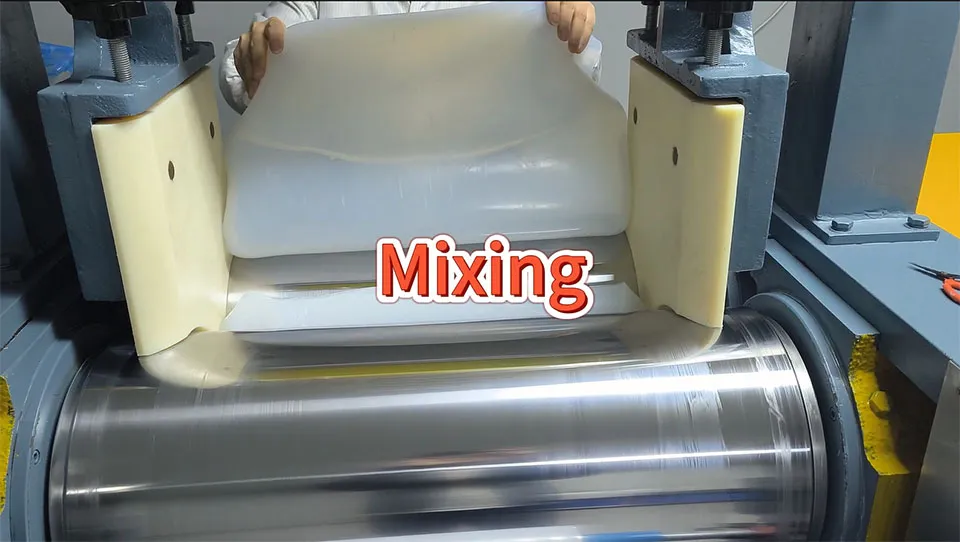

Silicone Mixing: What Is It?

Silicone mixing is a process of mixing silicone rubber raw materials with various additives like vulcanizers and processing them into a uniform mixture. This process is a key step in the production of silicone products and directly affects the quality and performance of the final product. The silicone rubber mixing process is usually carried out in a rubber mixer, where mechanical force and heat are used to fully mix and disperse the various ingredients.

Importance Of Mixing Process

The silicone mixing process is a crucial step in producing high-quality rubber products. Evenly mixed and dispersed additives can significantly improve the mechanical properties, aging resistance, wear resistance, and processing performance of rubber. A poor rubber mixing process may lead to uneven distribution of additives, bubbles or other defects, which will affect the performance and service life of the final product.

How To Silicone Mixing?

1. Silicone Mixing Preparation

Choosing The Right Worker

Silicone mixing is a complex technical job that requires experienced rubber mixing person to operate. If the wrong operator is selected, a series of common problems will arise, such as insufficient mixing, inconsistent colors, etc.

Selecting the Right Raw Materials

The preparation of mixing raw materials is crucial. Different materials are selected according to the hardness, practicality and tensile strength required for different products.

Choosing the Right Silicone Mixer

Selecting the appropriate silicone mixer is essential. The market offers a range of options, the most common rubber mixers are open mill mixers, internal mixers, and intensive mixers, each with its own distinct advantages.

Selecting Mixing Containers

The choice of mixing containers extends beyond functionality. The material of the container needs to work well with the initial substances to avoid any chemical interactions or mix-ups. For example, when incorporating additives such as carbon black, the containers need to be resistant to getting stained. It’s also extremely important to make sure that the containers are completely free of any leftover materials from earlier productions, highlighting the importance of deep cleaning.

Storage and Handling

Unprocessed materials are delicate components, prone to deterioration when not treated with accuracy. Contact with water, changes in temperature, and possible impurities act as harmful elements. Creating a regulated setting with controlled temperature and humidity is a key approach to safeguarding the quality of materials. This attention prevents the absorption of water and ensures the stability of the unprocessed materials.

2. Weighting And Measuring

The core of consistent material characteristics lies in the careful process of weighing and measuring raw materials. Even small changes in the proportions can lead to significant differences in the next batches, affecting the desired material traits. Advanced weighing devices and accurate measurement tools are used to achieve this goal: they guarantee precision and consistency. By following exact proportions with small error limits, the base of uniform quality is strengthened.

3.Pre-Blending

In situations where the raw materials come in different shapes or textures, pre-blending plays a vital part. This initial step guarantees that the materials are evenly mixed, preparing them for a smooth combination in the mixing stage. It also speeds up the following steps, improving the efficiency of the process of mixing silicone rubber.

4. Component Combination

Pour the measured components into a clean mixing container. Pour the base component first and then add the catalyst. Following this order ensures a uniform mixing process and reduces the risk of incomplete mixing.

5. Start Mixing

Carefully blend the natural silicone parts with a spatula or stick. Make sure to scrape the container’s edges and bottom while blending to guarantee everything is evenly combined. Keep mixing until every part is completely mixed and a consistent blend is achieved. The time it takes to mix can differ based on the natural silicone recipe but usually ranges from 1 to 5 minutes.

6. Check Consistency

During mixing, observe the texture and consistency of the silicone mixture. Ensure uniformity throughout the entire mixture, removing any lumps.

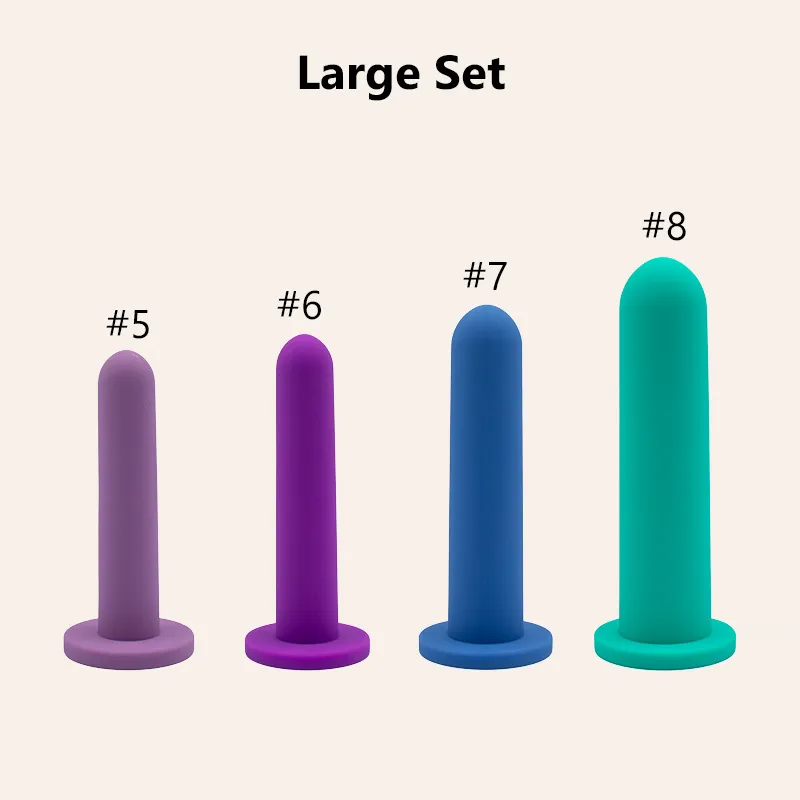

7. Silicone Color Mixing

Silicone colour mixing is also important, if your organic silicone formula requires special colours, add them at this step. Follow recommended guidelines for the quantity and timing of additive additions. Thoroughly mix to ensure an even distribution.

8. Cutting

Before the refining process is complete, cut the silicone material to the desired thickness and dimensions. This ensures efficient use of raw materials and prevents material waste and shortages during the shaping process.

Common Issues Of Silicone Mixing

As with all industrial processes, silicone mixing presents some issues and challenges. Some of these challenges are briefly described below:

Air Bubble Entrapment

The most common issue is air bubble entrapment, the air bubbles become trapped within the silicone mixture during the mixing process. Getting air bubbles caught inside can cause flaws on the outside or spots that are less strong in the end result. However, to reduce the chance of this happening, it’s important to mix the silicone parts gently and with caution. Moreover, using a vacuum degassing method can efficiently eliminate air bubbles from the blend.

Incomplete Mixing

Additionally, there’s the danger of insufficient blending, which could result in a patchy spread of the silicone ingredients – ultimately resulting in an unpredictable mixture of curing characteristics. It’s crucial to guarantee deep blending to prevent this and provide sufficient time for the blending procedure. Moreover, select appropriate mixing instruments and make sure to scrape well enough.

Inconsistent Color

Differences in the color of materials across various lots could suggest deeper problems. Small alterations in how pigment particles spread or changes in the way ingredients are mixed can lead to visible variations in color. The approach requires careful monitoring of how pigment is mixed in, steady regulation of temperature, and frequent maintenance of equipment used for mixing to avoid mixing different substances together.

Contamination

When foreign particles or substances get into the silicone mix, it becomes contaminated. This can affect its quality and homogeneity and lead to a degradation of performance.

Common Silicone Mixing Techniques

Visual Inspection

Visual inspection involves physically examining the mixed silicone material for possible side effects and structural defects. You search for bubbles, lumps, irregularities, discoloration, and additional issues.

Shore Hardness Testing

In shore hardness testing, the toughness of the silicone material after it has been set is evaluated. This is achieved by using a durometer gauge, which is applied to the silicone’s surface. After determining the hardness level, you can assess whether the silicone’s ability to withstand indentation is sufficient and whether it meets the appropriate criteria.

Tensile Strength Testing

In this area, you determine the silicone’s highest tensile strength when it has fully cured. You examine its elasticity, or how far it can be extended before it snaps. Typically, this examination is performed with a standard testing apparatus.

Compression Set Testing

In compression testing, you evaluate the silicone material’s ability to recover its original shape after being subjected to compression. You compress the material for a specific period, then measure the degree and time taken to recover.

Tear Resistance Testing

Tear strength evaluation assesses how well the silicone substance can withstand tearing or the spread of a tear. It aids in evaluating the substance’s strength and longevity. This evaluation process includes exerting pressure on a pre-made sample and noting the amount of force needed for the tear to spread.

Rheological Testing

Rheological testing examines the silicone material’s deformation and flows as it is mixed. It shows details such as the silicone material’s viscosity, shear thinning, and flow characteristics.

Thermal Analysis

Thermal analysis techniques include options like Differential Scanning Calorimetry (DSC) or Thermogravimetric Analysis (TGA). They help you to understand the material’s thermal properties, ranging from glass transition temperature and thermal stability.

Aging And Environmental Testing

Silicone materials are often subjected to aging or environmental testing to assess their long-term stability and performance.

This process may include exposing the fully hardened silicone specimens to high temperatures, moisture, ultraviolet light, or different environmental factors to replicate actual usage scenarios and examine how these conditions affect the material’s characteristics.