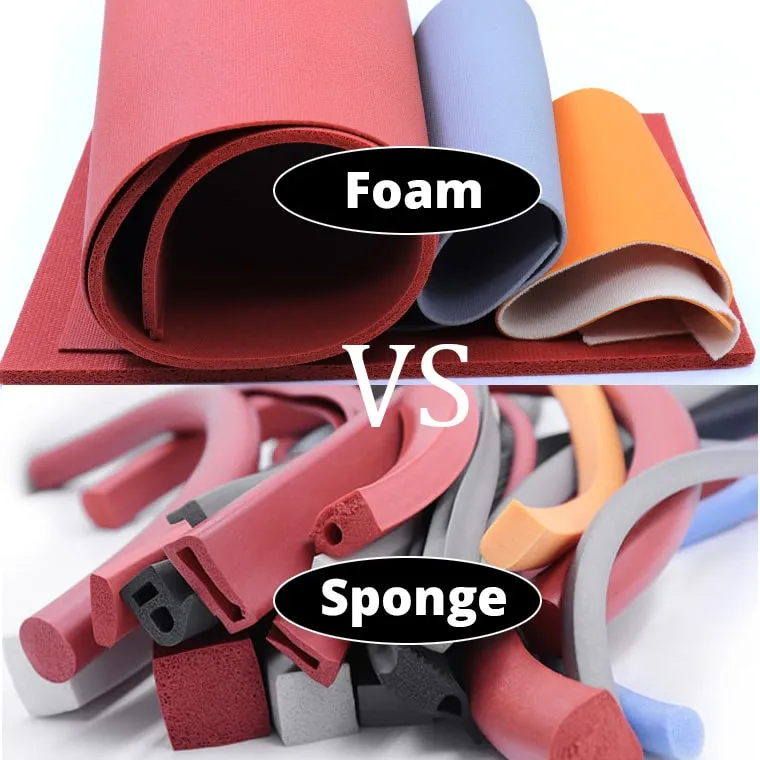

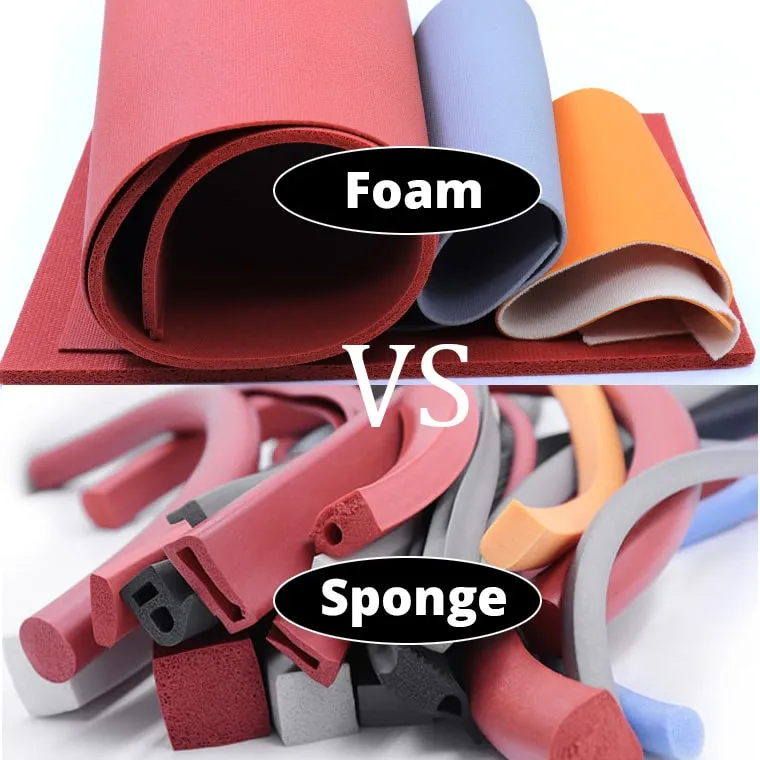

What is the difference between sponge and foam rubber?

Foam rubber and sponge rubber are both types of rubber materials that have undergone a cellular structure formation process. While they share similarities, there are differences between the two.

The foam material is made using foaming agents to create an air-filled structure. Sponge rubber broadly made-up of elastic and rubber-like material either in open cell or closed cell structure. Though both foam and sponge have low density, foam let the liquid pass through it, while sponge blocks the flow of liquid and gases.

How Are Foam and Sponge Rubbers Made?

Foam Rubber:

Foam rubber uses a chemical or gas called ‘blowing agent’ to generate a gas that creates thousands of bubbles in the liquid mixture. The liquid mixture consists of liquid polymers (Polyols, Polyisocyanates), water or colorants. Liquid polymers generate heat when mixed with water, and if we combine different liquid polymers, we can create flexible or rigid foam rubber depending upon the composition.

The blowing agents should be used in an accurate amount as they play a major role in making the foam flexible or rigid. Usually, manufacturers use carbon dioxide gas to make the foam flexible, while hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs) are used to form a more rigid foam rubber.

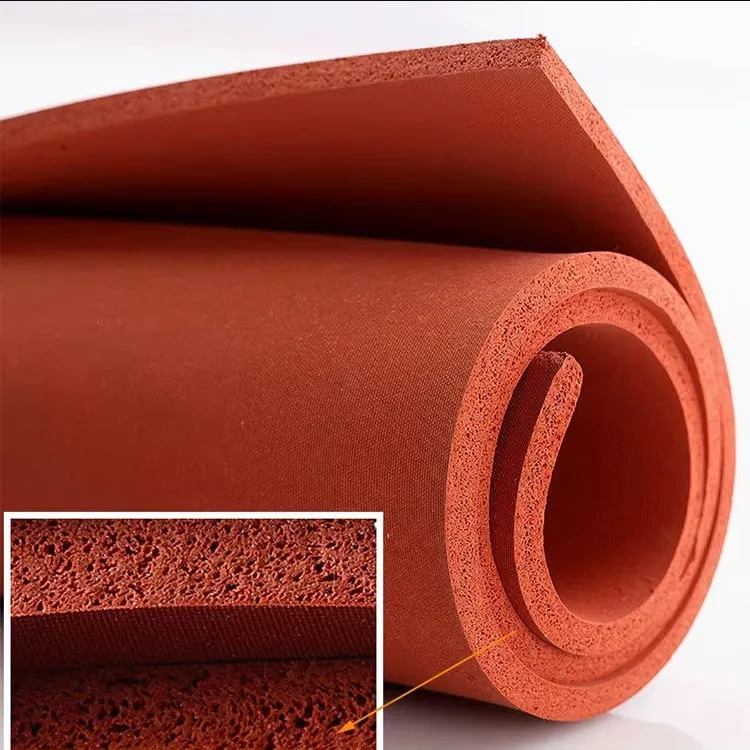

Sponge Rubber:

Sponge rubber is manufactured in the same way as foam rubber and has different densities (soft, medium, and firm). But there are two main types of sponge rubber- open-cell and closed-cell. Open-cell material has open and interconnected cells that allow air, water and other chemicals to pass when the material is loose. The gaps are formed by adding sodium bicarbonate to the heated mold with other ingredients to set the gaps in it.

Closed-cell material has closed cells that do not allow the passage of gaseous and liquid substance and make the rubber denser. Though the material has some gaps embedded, it is balloon-shaped and filled with nitrogen gas. The gaps here are formed by adding some chemical powder that decomposes when heated and some pressure is applied. It produces the nitrogen gas that closes the cells and gives it the needed strength and density.

Silicone sponge rubber is manufactured using gum-based polydimethylsiloxane (PMDS) that is heat cured to expand and create a closed structure. It is known across the world for its combining properties of closed cells with the lightness of the foam.

Now that we know how these are manufactured, let us discuss their uses.

Uses of Foam Rubber:

Polyurethane foams are useful in shock absorption and vibration control. These forms are rigid and do not spread when compressed. Some of the major applications include shock absorbers for industrial machinery, hood gaskets in mobile devices, and vibration isolators for different appliances.

Polystyrene foams are strong, light, and moisture resistant. Their high stiffness-to-weight ratio makes them a preferred choice for home and appliance insulation, lightweight product packaging, food packaging, surfboards, automobile parts, etc.

Reticulated foams (extremely open foams, like a net) are useful for filtration. Flexible foam rubber is used in soles and heels, automobile seats, mattresses and pillows. Rigid foam rubbers have their application in refrigerators and freezers.

Uses of Sponge Rubber:

Sponge rubbers are versatile and offer the following advantages-

It can be formed with low, medium, and high-density firmness.

High sealing ability

Can be compressed

Great shock absorption capability.

Sponge rubbers have been used in automotive, marine, public transport, and aviation sectors. Open-cell sponge rubber has its application in gaskets, seals, and protective padding, as it can resist sunlight and UV rays. Closed-cell sponge rubber is useful for cushioning, soundproofing, weather-stripping, thermal insulation, etc.

The uses of foam and sponge rubber are not limited to the areas mentioned above. However, these are some of the chief areas where they have been widely used time and again. Open and closed sponge rubber, made from different elastomers are widely used in multiple sectors like the auto industry, food and beverages packaging, medical packaging, chemical industry, electrical wires, etc.

JESilicone supplies custom made high quality closed cell sponge silicone rubber profiles in different size, shape and colors.If you are looking for silicone sponge gasket, extruded sponge rubber strips, silicone sponge tube visit www.jesilicone.com for more information. We can also make custom silicone rubber tubing, silicone rubber cord, extruded silicone gaskets, silicone rubber strips, molded rubber parts, vulcanized and splice silicone O-Rings, etc. Some of the market areas where our rubber products are in use include but not limited to