Shore Hardness | Definition, Characteristics, Applications, & Selection Guide

You may often hear the term "shore hardness" in the silicone rubber industry, but do you know exactly what shore hardness is?

Shore hardness measures how flexible and durable a material is. It determines the resistance of silicone rubber to deformation under pressure. The Shore A scale, ranging from 0 to 100, is commonly used for silicone rubber. Lower values indicate softer, more flexible materials, while higher values signify harder, less pliable ones. Choosing the right shore hardness ensures your silicone rubber performs effectively in its intended application. For instance, softer silicone suits molds with intricate details, while harder silicone withstands wear in demanding environments. This selection directly impacts usability, durability, and overall performance.

Key points about shore hardness you should know

- Shore hardness is crucial for determining the flexibility and durability of silicone rubber, impacting its performance in various applications.

- The Shore A scale, ranging from 0 to 100, helps you choose the right silicone rubber based on the required softness or hardness for your project.

- Softer silicone (Shore A 0-30) is ideal for applications needing flexibility, such as medical devices and intricate molds, while harder silicone (Shore A 70-90) excels in durability for automotive and industrial uses.

- Environmental factors like UV exposure and temperature should be considered when selecting shore hardness to ensure long-lasting performance.

- Testing and prototyping are essential steps to validate the chosen shore hardness, helping to identify potential issues before full-scale production.

- Choosing the right shore hardness not only enhances usability but also extends the lifespan of silicone rubber products, ensuring optimal performance.

Shore Hardness and Its Role in Silicone Rubber

What is Shore Hardness?

Shore hardness measures the resistance of a material to indentation. It provides a standardized way to evaluate the flexibility and rigidity of materials like silicone rubber. The Shore A scale is the most commonly used for silicone rubber, ranging from 0 to 100. Lower values on this scale indicate softer, more flexible materials, while higher values represent harder, more rigid ones. This scale helps you understand how a material will perform under pressure or stress.

The concept of shore hardness is essential for silicone rubber because it directly affects its usability. For example, ultra-soft silicone rubber with a low shore hardness is ideal for applications requiring high flexibility, such as molds with intricate details. On the other hand, harder silicone rubber with a higher shore hardness is better suited for applications that demand durability and resistance to wear.

How Shore Hardness is Measured

Shore hardness is measured using a device called a durometer. This tool presses a probe into the surface of the material with a specific amount of force. The depth of the indentation determines the hardness value. For silicone rubber, the Shore A durometer is typically used.

The testing process involves placing the material on a flat surface and applying the durometer probe. The reading appears on the scale, providing an accurate measure of the material's hardness. This method ensures consistency and reliability in evaluating silicone rubber properties. Industries rely on these measurements to maintain quality control and optimize performance during production.

Why Shore Hardness Matters for Silicone Rubber Applications

Shore hardness plays a critical role in determining the performance of silicone rubber in various applications. It impacts flexibility, durability, and resistance to deformation. Selecting the right shore hardness ensures that the silicone rubber meets the specific requirements of your project. For instance, softer silicone rubber is perfect for cushioning or sealing applications, while harder silicone rubber excels in structural components or high-wear environments.

Understanding shore hardness also helps you balance performance and longevity. Softer silicone may offer greater flexibility but could wear out faster under repeated use. Conversely, harder silicone provides better resistance to wear but may lack the flexibility needed for certain tasks. By choosing the appropriate shore hardness, you can ensure optimal performance and extend the lifespan of your silicone rubber products.

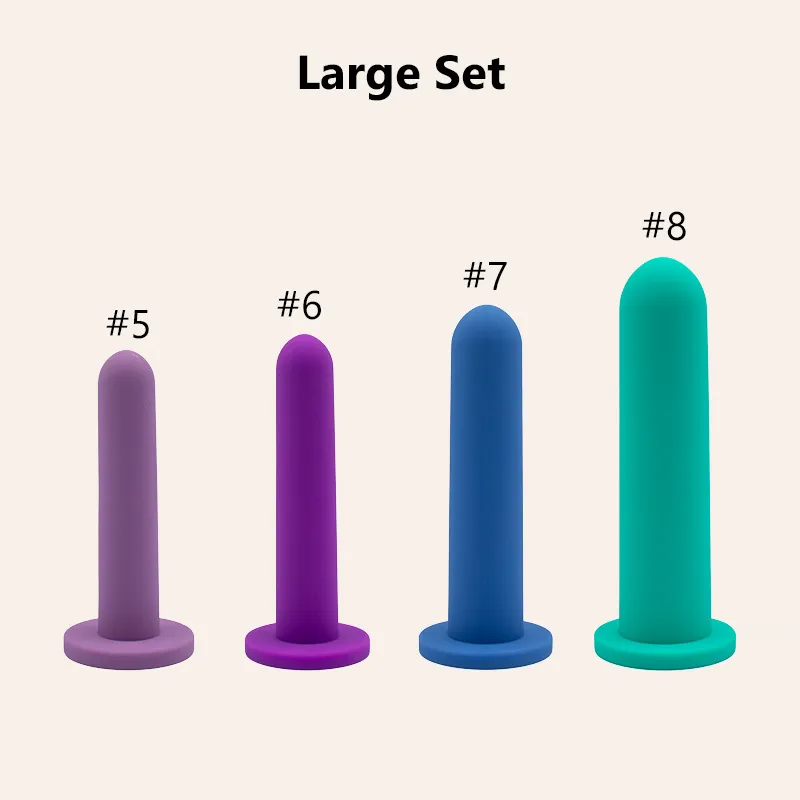

Shore A 0-10: Ultra-Soft Silicone Rubber

Characteristics of Ultra-Soft Silicone Rubber

Ultra-soft silicone rubber, with a Shore A hardness of 0-10, offers exceptional flexibility and softness. This material resists deformation while maintaining its pliability, making it ideal for applications requiring gentle contact. Its thermal stability ensures consistent performance across a wide temperature range. Additionally, it withstands exposure to outdoor elements, such as UV rays and moisture, without degrading.

This type of silicone rubber provides a smooth, soft texture that feels pleasant to the touch. It adapts well to intricate shapes and fine details, which makes it suitable for precision molding. Despite its softness, it retains durability, offering a balance between flexibility and resilience. These characteristics make ultra-soft silicone rubber a versatile choice for various industries.

Applications of Ultra-Soft Silicone Rubber

Ultra-soft silicone rubber serves a wide range of purposes across different fields. Its unique properties make it indispensable in many specialized applications:

- Medical Devices: This material is commonly used in medical-grade products, such as baby pacifiers, feeding nipples, and cushioning pads. Its softness ensures comfort and safety for sensitive users.

- Mold Making: The pliability of ultra-soft silicone rubber allows it to capture intricate details in molds. Artists and manufacturers use it to create replicas of complex designs.

- Sealing and Gaskets: Its ability to compress and conform makes it ideal for seals and gaskets in low-pressure environments. It prevents leaks while maintaining flexibility.

- Wearable Products: Ultra-soft silicone rubber is a popular choice for wearable items like wristbands and protective covers. Its soft texture enhances user comfort during prolonged use.

- Prototyping: Engineers and designers rely on this material for prototyping delicate components. Its adaptability helps refine designs before mass production.

0A hardness mold making silicone rubber

When it comes to creating molds with intricate details, 0A hardness mold making silicone rubber stands out as a game-changer. This ultra-soft material, measured on the Shore hardness scale, offers unmatched flexibility and precision. Its ability to conform to even the most delicate shapes makes it indispensable for mold-making projects. Whether you're crafting jewelry, prototypes, or artistic pieces, this 0A hardness mold making silicone rubber ensures every fine detail is captured. Its unique properties not only simplify the molding process but also enhance the quality of your final product.

Measuring 0A hardness involves using a durometer, a device designed to test the resistance of a material when pressure is applied. The durometer presses a small indenter into the silicone surface, and the reading reflects the material's hardness. A 0A reading indicates that the silicone rubber offers almost no resistance, highlighting its extreme softness.

This softness plays a critical role in mold making. It ensures that the silicone can wrap around complex shapes without tearing or losing detail. Whether you're casting resin, wax, or other materials, this flexibility guarantees that every curve and edge of your design is faithfully reproduced.

You might wonder why 0A hardness silicone rubber is so popular for mold making. The answer lies in its unique properties. Its ultra-soft nature allows it to capture fine details that harder materials might miss. This makes it invaluable for projects like jewelry molds, artistic sculptures, and prototypes.

Shore A 15-30: Soft Silicone Rubber

Characteristics of Soft Silicone Rubber

Soft silicone rubber, with a Shore A hardness of 15-30, offers a balance between flexibility and durability. This material provides enough softness to adapt to various shapes while maintaining structural integrity. Its pliable nature makes it suitable for applications requiring moderate compression without losing its form.

This type of silicone rubber resists environmental factors like UV rays, ozone, and moisture. It performs well in both indoor and outdoor settings, ensuring long-lasting reliability. Additionally, it remains thermally stable across a wide temperature range, making it a dependable choice for environments with fluctuating conditions. Despite its softer composition, it retains excellent tensile strength, ensuring resilience under stress.

Applications of Soft Silicone Rubber

Soft silicone rubber serves a variety of purposes across industries due to its versatile properties. Here are some common applications:

- Seals and Gaskets: Its flexibility allows it to create tight seals in moderate-pressure environments. You can use it for industrial gaskets or seals that need to prevent leaks while accommodating slight movements.

- Medical Products: Soft silicone rubber is a popular choice for medical-grade items like tubing, masks, and prosthetics. Its softness ensures comfort, while its durability supports repeated use.

- Consumer Goods: Many household items, such as kitchen utensils, phone cases, and protective covers, rely on soft silicone rubber for its pleasant texture and resilience.

- Cushioning Components: This material works well in padding or cushioning applications, such as shock absorbers or vibration dampeners. Its ability to compress and recover makes it ideal for these uses.

- Electrical Insulation: Soft silicone rubber provides excellent insulation for electrical components. Its resistance to heat and moisture ensures safety and performance in challenging conditions.

By choosing soft silicone rubber, you gain a material that combines adaptability with strength. Its unique characteristics make it a reliable option for projects requiring moderate flexibility and durability.

Shore A 40-60: Medium-Hard Silicone Rubber

Characteristics of Medium-Hard Silicone Rubber

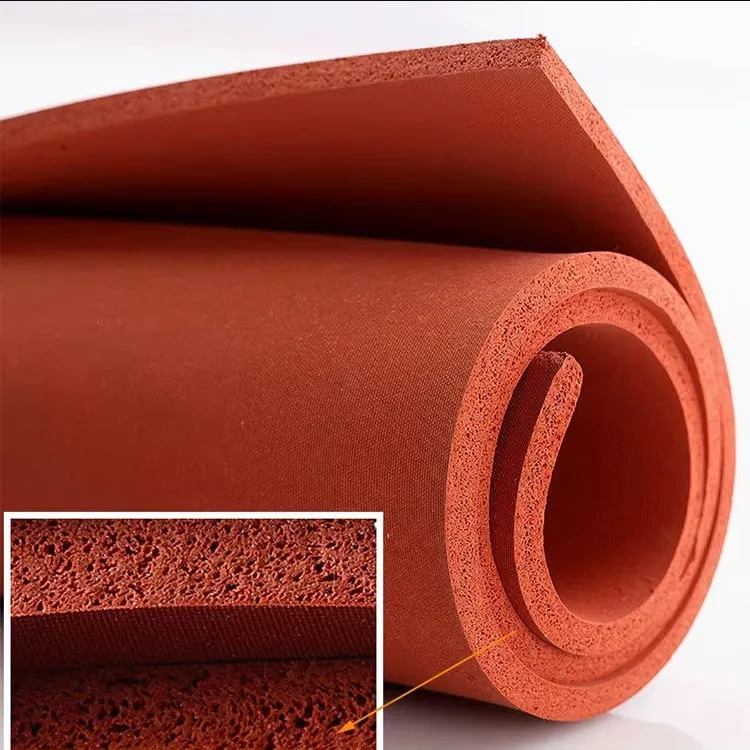

Medium-hard silicone rubber, with a Shore A hardness of 40-60, strikes a balance between flexibility and rigidity. This material offers enhanced durability while maintaining enough pliability to adapt to various applications. Its tensile strength and tear resistance make it a reliable choice for demanding environments. You can count on its ability to withstand repeated stress without losing its structural integrity.

This type of silicone rubber performs exceptionally well in both indoor and outdoor conditions. It resists UV rays, ozone, and moisture, ensuring long-lasting performance. Its thermal stability allows it to endure high temperatures, making it suitable for heat-intensive applications. Additionally, medium-hard silicone rubber exhibits low shrinkage, which ensures precision in applications requiring accurate detail reproduction.

Applications of Medium-Hard Silicone Rubber

Medium-hard silicone rubber serves a wide range of purposes across industries due to its versatile properties. Here are some common applications:

- Mold Making: This material excels in creating molds for epoxy resin, polyester, cement, concrete, and gypsum. Its ability to capture fine details ensures high-quality results. It also works well with low-melting-point metals, thanks to its heat resistance.

- Seals and Gaskets: Medium-hard silicone rubber is a popular choice for industrial gaskets and seals. Its durability and flexibility allow it to maintain tight seals under moderate to high pressure.

- Industrial Components: You can use this material for vibration dampeners, shock absorbers, and other components that require resilience under stress. Its tear resistance ensures longevity in these applications.

- Electrical Insulation: Medium-hard silicone rubber provides excellent insulation for electrical components. Its resistance to heat and environmental factors ensures safety and reliability.

- Consumer Products: Many household items, such as bakeware, protective covers, and durable mats, rely on medium-hard silicone rubber for its strength and adaptability.

By choosing medium-hard silicone rubber, you gain a material that combines toughness with versatility. Its unique characteristics make it a dependable option for projects requiring durability, precision, and thermal stability.

Shore A 70-90: Hard Silicone Rubber

Characteristics of Hard Silicone Rubber

Hard silicone rubber, with a Shore A hardness of 70-90, offers exceptional rigidity and durability. This material resists wear and deformation, making it ideal for demanding applications. Its high tensile strength ensures it can withstand significant mechanical stress without compromising its structure. You can rely on its excellent aging resistance, which allows it to maintain performance over time, even in harsh conditions.

This type of silicone rubber performs well in extreme environments. It resists UV rays, ozone, and moisture, ensuring long-lasting reliability. Its thermal stability allows it to endure high temperatures, making it suitable for heat-intensive applications. Additionally, hard silicone rubber provides superior mechanical support, which is essential for structural components and heavy-duty uses.

Applications of Hard Silicone Rubber

Hard silicone rubber serves a wide range of industrial and commercial purposes. Its unique properties make it indispensable in various fields:

- Automotive Parts: This material is a popular choice for gaskets, seals, and other components in vehicles. Its durability ensures it can handle the mechanical stress and high temperatures found in automotive environments.

- Engineering Machinery: Hard silicone rubber provides reliable mechanical support in heavy-duty equipment. Its resistance to wear and deformation makes it ideal for parts that experience constant pressure or movement.

- Mold Making: This material works well for molds that require rigidity and precision. It captures fine details while maintaining its shape under repeated use.

- Industrial Components: You can use hard silicone rubber for vibration dampeners, shock absorbers, and other parts that need to endure high stress. Its toughness ensures longevity in these applications.

- Consumer Products: Many durable household items, such as bakeware and protective covers, rely on hard silicone rubber for its strength and heat resistance.

By choosing hard silicone rubber, you gain a material that excels in strength, durability, and thermal stability. Its ability to perform under challenging conditions makes it a dependable option for projects requiring long-lasting and robust solutions.

Factors to Consider When Choosing Shore Hardness

Selecting the right shore hardness for silicone rubber is essential to ensure optimal performance and durability. Several factors influence this decision, and understanding them will help you make an informed choice.

Application-Specific Requirements

The intended use of silicone rubber plays a significant role in determining the appropriate shore hardness. Different applications demand varying levels of flexibility, durability, and resistance. For example:

- Medical Devices: Products like tubing or prosthetics require softer silicone rubber for comfort and adaptability.

- Industrial Components: Applications such as vibration dampeners or seals often need medium-hard to hard silicone rubber for enhanced durability and structural integrity.

- Consumer Goods: Items like phone cases or bakeware benefit from a balance between flexibility and toughness, typically found in medium-hard silicone rubber.

You should evaluate the specific needs of your project. Consider factors like the amount of stress the material will endure, the level of detail required, and the expected lifespan of the product. Selecting the correct shore hardness ensures that your silicone rubber meets these requirements effectively.

Environmental Conditions and Their Impact

Environmental factors significantly affect the performance of silicone rubber. Exposure to UV rays, moisture, ozone, or extreme temperatures can alter the material's properties over time. For instance:

- Outdoor Applications: Silicone rubber used outdoors must resist UV rays and weathering. Medium-hard or hard silicone rubber often performs better in such conditions.

- High-Temperature Environments: Applications involving heat, such as industrial machinery or bakeware, require silicone rubber with excellent thermal stability. Harder silicone rubber typically withstands high temperatures more effectively.

- Moisture-Prone Areas: In environments with high humidity or water exposure, silicone rubber with strong resistance to moisture degradation is essential.

By assessing the environmental conditions, you can choose a shore hardness that ensures long-lasting performance. Matching the material's properties to its environment is crucial for durability.

Importance of Testing and Prototyping

Testing and prototyping are critical steps in selecting the right shore hardness. Even with careful planning, real-world performance can differ from expectations. Prototyping allows you to evaluate how the silicone rubber behaves under actual conditions. This process helps you identify potential issues and make adjustments before full-scale production.

- Quality Control: Shore hardness testing ensures consistency in material properties during manufacturing. Using shore hardness tests during production helps optimize processes and maintain quality.

- Performance Validation: Prototypes let you assess whether the chosen shore hardness meets the application's demands. For example, you can test flexibility, durability, and resistance to wear in real-world scenarios.

Investing time in testing and prototyping minimizes risks and ensures that the final product performs as intended. This step is especially important for applications requiring precision or high durability.

In conclusion

The evolution of silicone rubber manufacturing has demonstrated the continuous need for understanding and accurately measuring Shore hardness. Shore hardness plays a vital role in determining the performance and durability of silicone rubber. Matching the right shore hardness to your specific application ensures optimal results, whether you need flexibility, rigidity, or a balance of both. To make the best choice, consult experts who can guide you through the selection process. Consider environmental factors like temperature and moisture, as these can impact material longevity. Always test prototypes to validate your decision before full-scale production. By understanding these factors, you can confidently explore silicone rubber options tailored to your needs.