Comparing Platinum Cured Silicone and Peroxide Cured Silicone: Assessing Properties, Applications, and Benefits

Platinum Cure Silicone and Peroxide Cure Silicone are very common words in silicone rubber industry. If you are new to silicone rubber industry, it may be create some confusion while choosing Platinum Cure Silicone or Peroxide Cure Silicone, because both are silicone grades with different curing mechanism and have their merits and demerits. In this article, we will try to provide a detailed comparison of them.

Introduction of Platinum Cured Silicone

Platinum cured silicone, also known as addition-cured silicone or platinum-catalyzed silicone, is a type of silicone rubber that is cured using platinum-based catalysts. It is widely used in various industries due to its exceptional properties and versatility.

Platinum cured silicone is created by mixing a two-part system: a platinum-based catalyst and a silicone base polymer. The platinum catalyst initiates a reaction that results in the cross-linking of the silicone polymer chains, forming a solid and flexible material.

Benifits of Platinum Cured Silicone

This type of silicone offers several advantages over other curing methods, such as peroxide curing. Some key characteristics of platinum cured silicone include:

High purity: Platinum cured silicone is known for its high degree of purity, making it suitable for applications that require a clean and biocompatible material. It has low levels of extractables and does not release byproducts during the curing process.

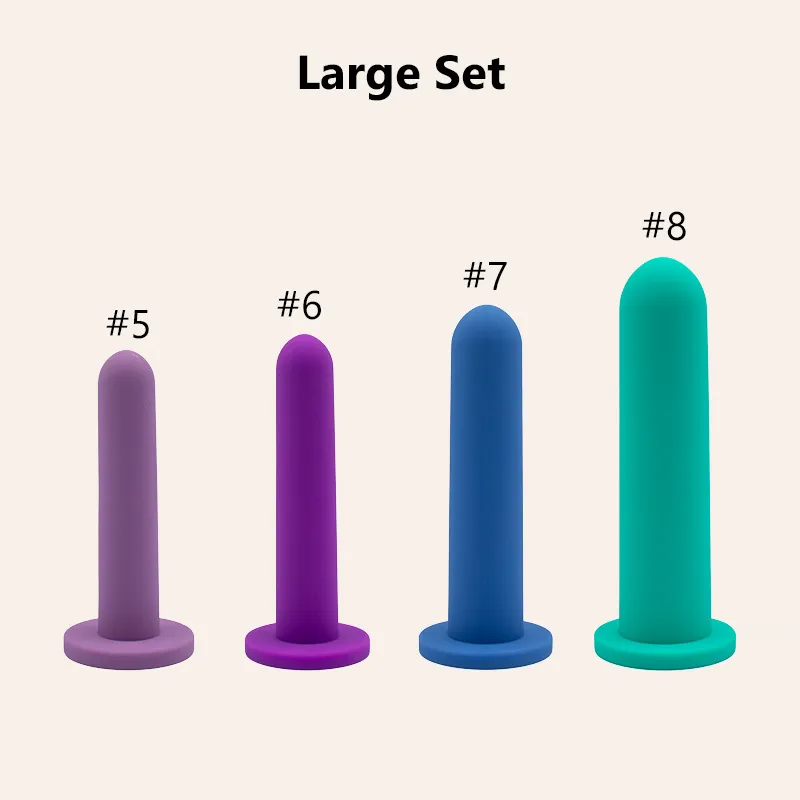

Enhanced transparency: Platinum cured silicone can be formulated to have excellent transparency, allowing for clear and see-through applications. This property is beneficial for industries like medical and optical, where transparency is essential.

Low shrinkage and excellent dimensional stability: Platinum cured silicone exhibits minimal shrinkage during the curing process, ensuring accurate replication of molds and precise dimensional stability in finished products.

Wide temperature range: This type of silicone can withstand a broad temperature range, from low temperatures to high heat conditions. It maintains its flexibility and mechanical properties over a wide temperature spectrum, making it suitable for demanding environments.

Good chemical resistance: Platinum cured silicone shows resistance to various chemicals, including solvents, acids, bases, and oils. This property makes it suitable for applications in chemical processing, pharmaceuticals, and food industries.

Biocompatibility: Platinum cured silicone is widely used in medical and healthcare applications due to its biocompatible nature. It is commonly used for medical implants, prosthetics, medical tubing, and other devices that come into contact with the human body.

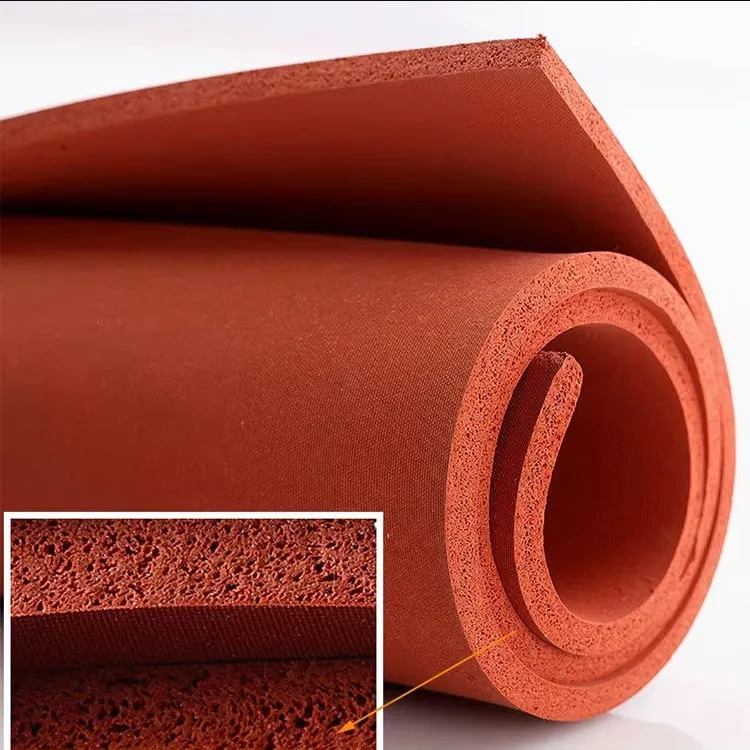

Introduction of Peroxide Cured Silicone

Curing of silicone elastomer using peroxide has been a customary approach for a long time. Peroxide cure procedure is clear and straightforward which use free radicals for cross-linking generated by organic peroxides. There are basically two parts: different kind of peroxides and the silicone gum resin.

Although the term “catalyst,” is used while peroxide cure, it isn’t in a proper manner a true catalyst reaction as it gets absorbed during the process. A peroxide inducted method is categorized as a second order reaction. It generally has three steps.

At the point when the silicone elastomer is put in the heated process, the peroxide thermally deteriorates to make free radicals. These free radicals strike either a methyl or a vinyl group, depending upon the polymer and peroxide utilized thus forming active cross link sites. The active sites on the silicone polymer at that point join, framing a carbon-carbon bond.