- HOME

-

PRODUCTS

High Temperature Silicone Tubing

Flexible Silicone Rubber Tubing

Large Diameter Silicone Tubing

High Temp Resistant Silicone Gasket

Custom Silicone Plug for Sealing

Custom Molded Rubber and Silicone Parts

Wholesale Silicone Molded Products

Custom Silicone Rubber Products

Custom Color Silicone Foam Tubing

Silicone Foam Tubing for Handle Grip

Sponge Silicone Rubber Products

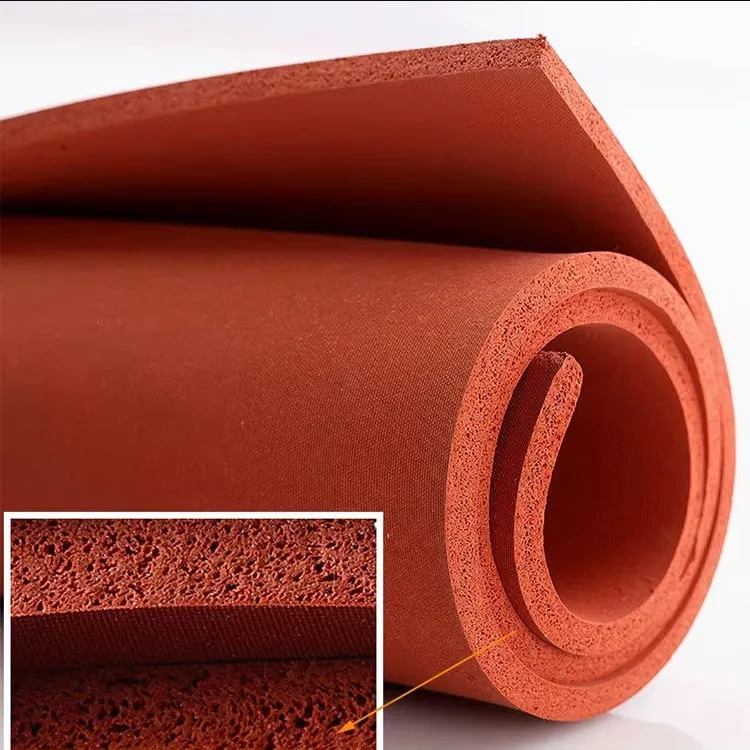

Environmental Soft Silicone Foam Sheet

High Temperature Silicone Foam Sheet

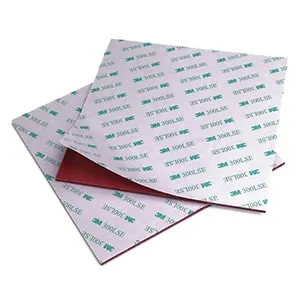

Insulating Shock-absorbing Foam Sheet

Smooth Surface Silicone Foam Sheet

Flame Retardant Silicone Strip

Silicone Door And Window Seal Strip

- GALLERY

-

ABOUT US

Your trustworthy silicone rubber products provider.

A well-known special silicone rubber products provider that integrates the research, development, production and sales.

Authorized certifications for strict product quality control and international market entry.

Established in 2007, the 50,000sqm Jiajie Manufacturing Base owns the most advanced automatic production lines in China to reach volume production capacity up to 60tons/month, ranking the frontline in the world.

-

CUSTOMIZITION (OEM/ODM)

One-stop Service / Your satisfaction, our motivation.

Frequently asked questions about silicone products.

-

NEWS

Keep updated with Jiajie about the latest silicone products, technologies and industry trends.

Acquire useful and popular knowledge regarding the silicone industry.

- Request for Quote